Abstract

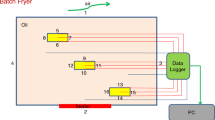

In this paper, the development of new models to determine heat and mass transfer parameters (HMTPs) in terms of the thermal diffusivity, heat transfer coefficient, moisture diffusivity and moisture transfer coefficient for slab, cylindrical, and spherical products being deep-fried was presented. In the model development, two cases of the Biot number, i.e., 0<Bi<100, and Bi≥100 in the transient heat and mass transfer were considered. In order to verify the models, frying experiments were performed using the cylindrically shaped potatoes as test samples, and these samples were fried in a deep fryer at 180°C. The lag factor and frying coefficient for a frying process, which affect heat and mass transfer parameters, were first-defined and considered most important process parameters. By using the temperature and moisture measurements, the frying coefficient and lag factor were determined and incorporated into the models. The HMTPs were determined in a simple and effective manner. In this respect, we can conclude that the present models are useful tools for determining the HMTPs for the products during frying and will be beneficial to the practical applications.

Zusammenfassung

In der Arbeit werden Modelle vorgestellt, über die sich Wärme- und Stoffübergangsparameter als Funktionen der Temperatur- und Feuchteleitfähigkeit und der Wärme- und Stoffübergangskoeffizienten für platten-, zylinder- und kugelförmige Nahrungsmittel beim Tauchgaren bestimmen lassen. Im instationären Wärme- und Stoffaustauschmodell werden zwei Bereiche der Biot-Zahl betrachtet: 0≤Bi≤100 und Bi≥100. Die Modellvorstellungen konnten durch Garexperimente bei 180°C an zylindrisch vorgeformten Kartoffelstücken verifiziert werden. Als wichtigste Prozeßparameter wurden über Temperature- und Feuchtegehaltsmessungen ein Verzögerungsfaktor und ein Garkoeffizient ermittelt und hieraus, in sehr einfacher und effektiver Weise, die interessierenden Wärme- und Stoffaustauschparameter. Es zeigte sich, daß die vorgeschlagenen Modelle recht gut geeignet sind, um die relevanten Wärme- und Stoffübergangsparameter für zum Tauchgaren bestimmte Produkte ermitteln zu helfen.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received on 22 January 1996

Rights and permissions

About this article

Cite this article

Dincer, I. Modelling for heat and mass transfer parameters in deep-frying of products. Heat and Mass Transfer 32, 109–113 (1996). https://doi.org/10.1007/s002310050099

Issue Date:

DOI: https://doi.org/10.1007/s002310050099