Abstract

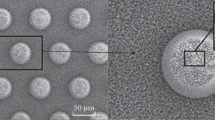

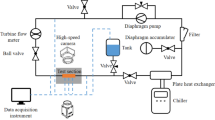

In order to explore boiling-heat-transfer performances for different surface morphologies, a boiling model was established via the volume-of-fluid (VOF) method. Four kinds of micron-scale pit and protrusion heat-transfer surfaces were designed, and these surfaces on boiling-heat-transfer performance were explored. Additionally, the temperature, heat-transfer coefficient, phase-volume fraction, and flow-velocity distribution of each heat-exchange surface were used to find an optimal structure. When the heat-transfer surface temperature was lower than 378 K, the truncated-cone-pit and cylindrical-pit structures exhibited the best heat transfer capacity due to shorter nucleation time. With an increase of heat-exchange surface temperature in the cylindrical-pit structure, film boiling occurs because of the small space between the microstructures, and the heat-transfer capacity decreases sharply. The film boiling that occurs in the truncated-cone-pit structure is due to the narrow outlet. When the heat-transfer surface temperature is higher than 378 K, the truncated-cone-protrusion structure shows the highest heat-transfer coefficient and, correspondingly, the lowest heat-transfer surface temperature.

Similar content being viewed by others

References

Leach F, Kalghatgi G, Stone R, Miles P (2020) The scope for improving the efficiency and environmental impact of internal combustion engines. Transp Eng 1. http://doi.org/10.1016/j.treng.2020.100005

Kalghatgi GT (2015) Developments in internal combustion engines and implications for combustion science and future transport fuels. Proc Combust Inst 35(1):101–115. https://doi.org/10.1016/j.proci.2014.10.002

Yuan X, Cai Y (2021) Forecasting the development trend of low emission vehicle technologies: Based on patent data. Technol Forecast Soc Chang 166(4):120651. https://doi.org/10.1016/j.techfore.2021.120651

Razmjooei B, Ravangard AR, Momayez L, Ferchichi M (2021) The influence of heat transfer due to radiation heat transfer from a combustion chamber. J Therm Anal Calorim 15:1–17. https://doi.org/10.1007/s10973-020-10263-3

Hyun SB, Lee DR (2020) A study on cooling performance augmentation of water-cooling and optimization design utilizing carbon material in electric vehicle secondary battery J Korean Soc Precis Eng 37. https://doi.org/10.7736/JKSPE.020.043

Saneie N, Kulkarni V, Treska B, Fezzaa K, Anand S (2021) Microbubble dynamics and heat transfer in boiling droplets. Int J Heat Mass Transf 176(4):121413. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121413

Zhao Z, Ma X, Li S, Yang S, Huang L (2020) Visualization-based nucleate pool boiling heat transfer enhancement on different sizes of square micropillar array surfaces-Science Direct. Exp Thermal Fluid Sci 119. https://doi.org/10.1016/j.expthermflusci.2020.110212

Gao L, Lyu J, Bai M, Li Y, Shi L (2021) The microchannel combined hydrophobic nanostructure for enhancing boiling heat transfer. Appl Therm Eng 194:116962. https://doi.org/10.1016/j.applthermaleng.2021.116962

Dedov AV (2019) A review of modern methods for enhancing nucleate boiling heat transfer. Therm Eng 66(12):881–915. https://doi.org/10.1134/S0040601519120012

Yu T, Cui C, Qi B, Wei J, Qaisrani MA (2020) Boiling heat transfer and bubble distribution on inhomogeneous wetting surface patterned with sierpinski carpet. Appl Therm Eng 180(14):115818. https://doi.org/10.1016/j.applthermaleng.2020.115818

Jacob M (1936) Heat transfer in evaporation and condensation II. Mech Eng 58:729–740

Lv Y, Liu MY, Hui LF, Pavlenko AN, Surtaev AS, Serdyukov VS (2019) Heat transfer and fouling rate at boiling on superhydrophobic surface with TiO2 nanotube-array structure. J Eng Thermophys 28(2):163–176. https://doi.org/10.1134/S1810232819020012

Fisenko S, Bobb J, Rodrigues CJ, Ei-Shall KM (2019) Nucleation of gold nanoparticles in a solution via laser hell: simulation and experiments. Int J Nanosci 18(3&4):1940059. https://doi.org/10.1142/S0219581X19400593

Bruder M, Riffat P, Sattelmayer T (2019) Identification of universal heat transfer characteristics along the boiling curve for vertical subcooled flow boiling of refrigerant Novec 649. Heat Mass Transf (2). https://doi.org/10.1007/s00231-019-02675-1

Hosseini R, Gholaminejad A, Nabil M (2011) Concerning the effect of surface material on nucleate boiling heat transfer of R-113. Journal of Electronics Cooling & Thermal Control 1(2):22–27. https://doi.org/10.1115/AJTEC2011-44498

Choi C, Yoo HS, Oh JM (2008) Preparation and heat transfer properties of nanoparticle-in-transformer oil dispersions as advanced energy-efficient coolants. Curr Appl Phys 8(6):710–712. https://doi.org/10.1016/j.cap.2007.04.060

Leongab KY, Saidura R, Kazia SN, Mamunc AH (2010) Performance investigation of an automotive car radiator operated with nanofluid-based coolants (nanofluid as a coolant in a radiator)-Science Direct. Appl Therm Eng 30(17–18):2685–2692. https://doi.org/10.1016/j.applthermaleng.2010.07.019

Kiyomura IS, Nunes JM, Souza RRD, Gajghate SS, Bhaumik S, Cardoso EM (2020) Effect of microfin surfaces on boiling heat transfer using HFE-7100 as working fluid. J Braz Soc Mech Sci Eng 42(7):1–13. https://doi.org/10.1007/s40430-020-02439-7

Zhang J, Guan Y, Lin W, Gu X (2019) Enhanced mechanical properties and biocompatibility of Mg-Gd-Ca alloy by laser surface processing. Surf Coat Technol 362:176–184. https://doi.org/10.1016/j.surfcoat.2019.01.063

Yang GF, Zhang H, Li HW, Lu MK, Zhai W, Cui J (2020) Experimental study on the ice suppression characteristics of TC4 microstructure surface induced by femtosecond pulsed laser. Surf Coat Technol 405. https://doi.org/10.1016/j.surfcoat.2020.126558

Wen HY, Chen JL, Chiang CC (2020) Square-wave long-period fiber grating fabricated with double-sided laser-assisted wetetching technology. IEEE Sens J 99:1–1. https://doi.org/10.1109/JSEN.2020.2978872

Omar H, Hashim MR, Pakhuruddin MZ (2021) Surface morphological and optical properties of flexible black silicon fabricated by metal-assisted chemical etching. Opt Laser Technol 136:106765. https://doi.org/10.1016/j.optlastec.2020.106765

Deng D, Wan W, Qin Y, Zhang J, Chu X (2017) Flow boiling enhancement of structured microchannels with micro pin fins. Int J Heat Mass Transf 105:338–349. https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.086

Moze M, Zupancic M, Hacvar M, Golobic I, Gregorcic P (2019) Surface chemistry and morphology transition induced by critical heat flux incipience on laser-textured copper surfaces. Appl Surf Sci 490(1):220–230. https://doi.org/10.1016/j.apsusc.2019.06.068

Das AK, Das PK, Saha P (2010) Some investigations on the enhancement of boiling heat transfer from planer surface embedded with continuous open tunnels. Exp Thermal Fluid Sci 34(8):1422–1431. https://doi.org/10.1016/j.expthermflusci.2010.06.017

Ha M, Graham S (2019) Pool boiling enhancement using vapor channels in microporous surfaces. Int J Heat Mass Transf 143:118532. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118532

Kuo CJ, Peles Y (2009) Pressure effects on flow boiling instabilities in parallel microchannels. Int J Heat Mass Transf 52(1–2):271–280. https://doi.org/10.1016/j.ijheatmasstransfer.2008.06.015

Deng D, Wan W, Tang Y, Wan Z, Liang D (2015) Experimental investigations on flow boiling performance of reentrant and rectangular microchannels-A comparative study. Int J Heat Mass Transf 82:435–446. https://doi.org/10.1016/j.ijheatmasstransfer.2014.11.074

Xue F, Taslim ME (2018) Detailed flow and heat transfer analyses in a rib-roughened trailing-edge cooling cavity with im**ement. J Turbomach 10(1115/1):4041818

Bova S, Castiglione T, Piccione F, Pizzonia F (2015) A dynamic nucleate-boiling model for CO2 reduction in internal combustion engines. Appl Energy 143. https://doi.org/10.1016/j.apenergy.2015.01.047

Torregrosa AJ, Broatch A, Olmeda P, Cornejo O (2014) Experiments on subcooled flow boiling in I.C. engine-like conditions at low flow velocities. Exp Thermal Fluid Sci 52:347–354. https://doi.org/10.1016/j.expthermflusci.2013.10.004

Punekar H, Das S (2013) Numerical simulation of subcooled nucleate boiling in cooling jacket of IC engine. Sae World Congress & Exhibition.

Dong F, Hou L, Xu Z, Cao TT (2017) SAE Technical Paper Series [SAE International WCX™ 17: SAE World Congress Experience - (APR. 04, 2017)] SAE Technical Paper Series-Simulation of subcooled flow boiling on engine cooling jacket with a bubble waiting time coefficient model. https://doi.org/10.4271/2017-01-0139

Hara T, Kato S (2004) Numerical simulation of thermal plumes in free space using the standard k–ε model. Fire Saf J 39(2):105–129. https://doi.org/10.1016/j.firesaf.2003.07.005

Dong F, Hou L, Jiang L, Ni J (2017) Simulation of subcooled flow boiling with an SVR based interphase mass transfer model. Applied Thermal Engineering 116(Complete):840–849. https://doi.org/10.1016/j.applthermaleng.2016.12.067

Zhu C, Li X, Song L, **ang L (2013) Development of a theoretically based thermal model for lithium ion battery pack. J Power Sources 223(none):155–164. https://doi.org/10.1016/j.jpowsour.2012.09.035

Lei G, Zhang SS, Cheng L (2011) Study on characteristics of vapor–liquid two-phase flow in mini-channels. Nucl Eng Des 241(10):4158–4164. https://doi.org/10.1016/j.nucengdes.2011.07.014

Robert JM (1988) Describing the uncertainties in experimental results. Exp Thermal Fluid Sci. https://doi.org/10.1016/0894-1777(88)90043-X

Zhang Y, Liu B, Liu Y, Yang Y, Wei J (2019) Experimental study on the pool boiling heat transfer enhancement with micro/nanostructured surfaces. Interfacial Phenomena and Heat Transfer 7(1). https://doi.org/10.1615/InterfacPhenomHeatTransfer.2019030616

Surtaev AS, Serdyukov VS, Malakhov IP (2020) Features of boiling heat transfer at various pressures on hydrophilic/hydrophobic surfaces. J Eng Thermophys 29(4):582–591. https://doi.org/10.1134/S1810232820040062

Acknowledgements

This work was funded by National Natural Science Foundation of China [Grant No. 51406070], Natural Science Foundation of Jiangsu Province of China [Grant No. BK20140548], Natural Science Foundation of the Jiangsu Higher Education Institutions of China [Grant No. 14KJB470001], and A Project of the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, R., Wang, Z. & Dong, F. Influence of heat-transfer surface morphology on boiling-heat-transfer performance. Heat Mass Transfer 58, 1303–1318 (2022). https://doi.org/10.1007/s00231-022-03179-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03179-1