Abstract

The thermal conductivity is a key parameter to study the applicability of nanofluids for heat transfer enhancement of flowing liquids. This paper is an effort on implementing various methods to model the effective thermal conductivity of 26 nanofluids under different situations and evaluate the authenticity of the reported experimental data in the open literature. The most influential physical properties of nanofluids, such as the nanoparticle volume fraction, nanoparticle diameter, thermal conductivity of base fluid, temperature, and thermal conductivity of solid particle are considered as the input variables. With the purpose of introducing a comprehensive and pragmatic model with desired accuracy, a Multilayer Perceptron-Artificial Neural Network (MLP-ANN) approach is constructed and tested using data generated from 993 experiments. To appraise the creditability of the MLP-ANN model, a comparison with other 10 alternative techniques is carried out. The predictions made by the MLP-ANN yield excellent match with the experimentally generated samples against those of the other approaches. The coefficient of determination and relative root mean squared error are found to be 0.994 and 1.534%, respectively. Likewise, the results of the data analysis and the outlier detection method have proved that some of the data samples are significantly inconsistent with the remainder of the data set.

Similar content being viewed by others

References

Das PK (2017) A review based on the effect and mechanism of thermal conductivity of normal nanofluids and hybrid nanofluids. J Mol Liq 240:420–446

Chen T, Kim J, Cho H (2014) Theoretical analysis of the thermal performance of a plate heat exchanger at various chevron angles using lithium bromide solution with nanofluid. Int J Refrig 48:233–244

Buschmann MH, Franzke U (2014) Improvement of thermosyphon performance by employing nanofluid. Int J Refrig 40:416–428

Sozen A, Ozbas E, Menlik T, Cakır MT, Guru M, Boran K (2014) Improving the thermal performance of diffusion absorption refrigeration system with alumina nanofluids: an experimental study. Int J Refrig 44:73–80

Khan JA, Mustafa M, Hayat T, Farooq M, Alsaedi A, Liao SJ (2014) On model for three-dimensional flow of nanofluid: an application to solar energy. J Mol Liq 194:41–47

Azmi WH, Sharma KV, Mamat R, Najafi G, Mohamad MS (2016) The enhancement of effective thermal conductivity and effective dynamic viscosity of nanofluids-a review. Renew Sust Energ Rev 53:1046–1058

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement for nanofluids. J Heat Transf 125:567–574

Timofeeva EV, Gavrilov AN, McCloskey JM, Tolmachev YV (2007) Thermal conductivity and particle agglomeration in alumina nanofluids: experiment and theory. Phys Rev E 76:061203

Oh D-W, Jain A, Eaton JK, Goodson KE, Lee JS (2008) Thermal conductivity measurement and sedimentation detection of aluminum oxide nanofluids by using the 3ω method. Int J Heat Fluid Flow 29:1456–1461

Kim SH, Choi SR, Kim D (2007) Thermal conductivity of metal-oxide nanofluids: particle size dependence and effect of laser irradiation. J Heat Transf 129:298–307

Patel HE, Sundararajan T, Das SK (2010) An experimental investigation into the thermal conductivity enhancement in oxide and metallic nanofluids. J Nanopart Res 12:1015–1031

Gu Y, Xu S, Wu X (2018) Thermal conductivity enhancements and viscosity properties of water based nanofluid containing carbon nanotubes decorated with ag nanoparticles. Heat Mass Transf 54:1847–1852

Ebrahimi S, Saghravani SF (2018) Experimental study of the thermal conductivity features of the water based Fe3O4/CuO nanofluid. Heat Mass Transf 54:999–1008

Godson L, Raja B, Lal DM, Wongwises S (2010) Experimental investigation on the thermal conductivity and viscosity of silver-deionized water nanofluid. Experimental Heat Transfer 23:317–332

Hamilton R, Crosser O (1962) Thermal conductivity of heterogeneous two-component systems. Ind Eng Chem Fundam 1:187–191

Wasp EJ, Kenny JP, Gandhi RL (1977) Solid-liquid flow slurry pipeline transportation. In: Series on bulk materials handling, vol 1. Trans Tech Publications, Clausthal, p 224

Xue QZ (2005) Model for thermal conductivity of carbon nanotube-based composites. Phys B Condens Matter 368:302–307

Li CH, Peterson GP (2006) Experimental investigation of temperature and volume fraction variations on the effective thermal conductivity of nanoparticle suspensions (nanofluids). J Appl Phys 99:084314

Mintsa HA, Roy G, Cong TN, Doucet D (2009) New temperature dependent thermal conductivity data for water-based nanofluids. Int J Therm Sci 48:363–371

Yang L, Xu J, Du K, Zhang X (2017) Recent developments on viscosity and thermal conductivity of nanofluids. Powder Technol 317:348–369

Nabipour M, Keshavarz P (2017) Modeling surface tension of pure refrigerants using feed-forward back-propagation neural networks. Int J Refrig 75:217–227

Deng S, Su W, Zhao L (2016) A neural network for predicting normal boiling point of pure refrigerants using molecular groups and a topological index. Int J Refrig 63:63–71

Zendehboudi A, Wang B, Li X (2017) Robust model to predict the migration ratios of nanoparticles during the pool-boiling process of nanorefrigerants. International Communications in Heat and Mass Transfer 84:75–85

Zendehboudi A (2016) Implementation of GA-LSSVM modelling approach for estimating the performance of solid desiccant wheels. Energy Convers Manag 127:245–255

Zendehboudi A, Tatar A (2017) Utilization of the RBF network to model the nucleate pool boiling heat transfer properties of refrigerant-oil mixtures with nanoparticles. J Mol Liq 247:304–312

Zendehboudi A, Wang B, Li X (2017) Application of smart models for prediction of the frost layer thickness on vertical cryogenic surfaces under natural convection. Appl Therm Eng 115:1128–1136

Zendehboudi A, Tatar A (2017) Oil flooded scroll compressors: predicting the energy performance and evaluating the experimental data. Measurement 112:38–46

Zendehboudi A, Li X (2017) Robust predictive models for estimating frost deposition on horizontal and parallel surfaces. Int J Refrig 80:225–237

Zendehboudi A, Li X, Wang B (2017) Utilization of ANN and ANFIS models to predict variable speed scroll compressor with vapor injection. Int J Refrig 74:473–485

Mehrabi M, Sharifpur M, Meyer JP (2012) Application of the FCM-based neuro-fuzzy inference system and genetic algorithm-polynomial neural network approaches to modelling the thermal conductivity of alumina–water nanofluids. International Communications in Heat and Mass Transfer 39:971–977

Esfe MH, Saedodin S, Sina N, Afrand M, Rostami S (2015) Designing an artificial neural network to predict thermal conductivity and dynamic viscosity of ferromagnetic nanofluid. International Communications in Heat and Mass Transfer 68:50–57

Esfe MH, Afrand M, Yan W-M, Akbari M (2015) Applicability of artificial neural network and nonlinear regression to predict thermal conductivity modeling of Al2O3-water nanofluids using experimental data. International Communications in Heat and Mass Transfer 66:246–249

Afrand M, Toghraie D, Sina N (2016) Experimental study on thermal conductivity of water-based Fe3O4 nanofluid: development of a new correlation and modeled by artificial neural network. International Communications in Heat and Mass Transfer 75:262–269

Yousefi F, Mohammadiyan S, Karimi H (2016) Application of artificial neural network and PCA to predict the thermal conductivities of nanofluids. Heat Mass Transf 52:2141–2154

Esfe MH, Saedodin S, Bahiraei M, Toghraie D, Mahian O, Wongwises S (2014) Thermal conductivity modeling of MgO/EG nanofluids using experimental data and artificial neural network. J Therm Anal Calorim 118:287–294

khosrojerdi S, Vakili M, Yahyaei M, Kalhor K (2016) Thermal conductivity modeling of graphene nanoplatelets/deionized water nanofluid by MLP neural network and theoretical modeling using experimental results. International Communications in Heat and Mass Transfer 74:11–17

Esfahani JA, Safaei MR, Goharimanesh M, Oliveira LRD, Goodarzi M, Shamshirband S, Filho EPB (2017) Comparison of experimental data, modelling and non-linear regression on transport properties of mineral oil based nanofluids. Powder Technol 317:458–470

Jiang H, Li H, Zan C, Wang F, Yang Q, Shi L (2014) Temperature dependence of the stability and thermal conductivity of an oil-based nanofluid. Thermochim Acta 579:27–30

Chon CH, Kihm KD, Lee SP, Choi SUS (2005) Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl Phys Lett 87:153107

Timofeevaa EV, Moravekb MR, Singh D (2011) Improving the heat transfer efficiency of synthetic oil with silica nanoparticles. J Colloid Interface Sci 364:71–79

Pastoriza-Gallego MJ, Lugo L, Cabaleiro D, Legido JL, Piñeiro MM (2014) Thermophysical profile of ethylene glycol-based ZnO nanofluids. J Chem Thermodyn 73:23–30

Khedkar RS, Sonawane SS, Wasewar KL (2012) Influence of CuO nanoparticles in enhancing the thermal conductivity of water and monoethylene glycol based nanofluids. International Communications in Heat and Mass Transfer 39:665–669

Murshed SMS (2012) Simultaneous measurement of thermal conductivity, thermal diffusivity, and specific heat of nanofluids. Heat Transfer Engineering 33:722–731

Mondragón R, Segarra C, Martínez-Cuenca R, Juliá JE, Jarque JC (2013) Experimental characterization and modeling of thermophysical properties of nanofluids at high temperature conditions for heat transfer applications. Powder Technol 249:516–529

Halelfadl S, Maré T, Estellé P (2014) Efficiency of carbon nanotubes water based nanofluids as coolants. Exp Thermal Fluid Sci 53:104–110

Lee S, Choi US, Li S, Eastman JA (1999) Measuring thermal conductivity of fluids containing oxide nanoparticles. J Heat Transf 121:280–289

Fedele L, Colla L, Bobbo S (2012) Viscosity and thermal conductivity measurements of water-based nanofluids containing titanium oxide nanoparticles. Int J Refrig 35:1359–1366

Thang BH, Khoi PH, Minh PN (2015) A modified model for thermal conductivity of car- bon nanotube-nanofluids. Phys Fluids 27:032002

Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ (2001) Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys Lett 78:718–720

Moghadassi AR, MasoudHosseini S, Henneke DE (2010) Effect of CuO nanoparticles in enhancing the thermal conductivities of monoethylene glycol and paraffin fluids. Ind Eng Chem Res 49:1900–1904

Murshed SMS, Leong KC, Yang C (2008) Investigations of thermal conductivity and viscosity of nanofluids. Int J Therm Sci 47:560–568

Godson L, Lal DM, Wongwises S (2010) Measurement of thermo physical properties of metallic nanofluids for high temperature applications. Nanoscale and Microscale Thermophysical Engineering 14:152–173

Esfe MH, Karimipour A, Yan WM, Akbari M, Safaei MR, Dahari M (2015) Experimental study on thermal conductivity of ethylene glycol based nanofluids containing Al2O3 nanoparticles. Int J Heat Mass Transf 88:728–734

Esfe MH, Saedodin S, Asadi A, Karimipour A (2015) Thermal conductivity and viscosity of Mg(OH)2–ethylene glycol nanofluids: finding a critical temperature. J Therm Anal Calorim 120:1145–1149

Wang W, Lin L, Feng Z, Wang S (2012) A comprehensive model for the enhanced thermal conductivity of nanofluids. Journal of Advanced Research in Physics 3:021209

Teng TP, Hung YH, Teng TC, Moa HE, Hsu HG (2010) The effect of alumina/water nanofluid particle size on thermal conductivity. Appl Therm Eng 30:213–2218

Kazemi-Beydokhti A, Heris SZ, Moghadam N, Shariati-Niasar M, Hamidi AA (2014) Experimental investigation of parameters affecting nanofluid effective thermal conductivity. Chem Eng Commun 201:593–611

Yousefi F, Karimi H, Mohammadiyan S (2016) Viscosity of carbon nanotube suspension using artificial neural networks with principal component analysis. Heat Mass Transf 52:2345–2355

Du K-L, Swamy MNS (2006) Neural networks in a soft computing framework. Springer, London

Aghaei A, Khorasanizadeh H, Sheikhzadeh GA (2018) Measurement of the dynamic viscosity of hybrid engine oil-Cuo-MWCNT nanofluid, development of a practical viscosity correlation and utilizing the artificial neural network. Heat Mass Transf 54:151–161

Goh ATC (1995) Back-propagation neural networks for modeling complex systems. Artif Intell Eng 9:143–151

Kaastra I, Boyd M (1996) Designing a neural network for forecasting financial and economic time. Neurocomputing 10:215–236

Mitchell TM (1997) Machine learning. McGraw Hill, New York

Gramatica P (2007) Principles of QSAR models validation: internal and external. QSAR Comb Sci 26:694–701

Rousseeuw PJ, Leroy AM (2005) Robust regression and outlier detection. Wiley, New York

Mohammadi AH, Eslamimanesh A, Gharagheizi F, Richon D (2012) A novel method for evaluation of asphaltene precipitation titration data. Chem Eng Sci 78:181–185

Eslamimanesh A, Gharagheizi F, Mohammadi AH, Richon D (2013) Assessment test of sulfur content of gases. Fuel Process Technol 110:133–140

Li M-F, Tang X-P, Wu W, Liu H-B (2013) General models for estimating daily global solar radiation for different solar radiation zones in mainland China. Energy Convers Manag 70:139–148

Ivakhnenko AG (1971) Polynomial theory of complex systems. IEEE Transactions on Systems, Man, and Cybernetics SMC-1:364–378

Jang JSR (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Transactions on Systems, Man, and Cybernetics 23:665–685

Suykens J, Vandewalle J (1999) Least squares support vector machine classifiers. Neural Process Lett 9:293–300

Vatani A, Woodfield PL, Dao DV (2015) A survey of practical equations for prediction of effective thermal conductivity of spherical-particle nanofluids. J Mol Liq 211:712–733

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

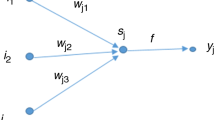

Figure 9 shows the architecture of the MLP-ANN developed in this study, including the input layer, hidden layers, and output layer. To make the outcomes of the model reproducible, the matrices of the weights and biases of all layers of the optimized trained model are presented.

Rights and permissions

About this article

Cite this article

Zendehboudi, A., Saidur, R. A reliable model to estimate the effective thermal conductivity of nanofluids. Heat Mass Transfer 55, 397–411 (2019). https://doi.org/10.1007/s00231-018-2420-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2420-5