Abstract

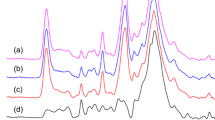

This study was carried out to elucidate the effect of defibration temperature in the range 171–202°C on the properties of 12-mm thick MDF boards made without synthetic resins from softwood fibers activated by laccase treatment for the generation of phenoxy radicals on the fiber surfaces. Laccase treatment generated radicals in the fibers. An increase in defibration temperature improved the reactivity of fibers during laccase-catalyzed oxidation. The number of radicals detected in the fibers after laccase treatment in water suspension and the fiber oxygen consumption during the treatments increased with an increase in defibration temperature, while a concurrent improvement was observed in the mechanical strength and thickness swell of dry-process MDF boards made from fibers refined at different temperatures and treated with laccase in the refiner blowline. The different fiber reactivities or board properties were not due to a presence of different amounts of lignin remaining on the fiber surfaces after acetone extraction. The probable reason for them was the fact that the amount of low-molecular weight lignin, a reactive substrate for laccase, increases with increasing defibration temperature. The adhesion occurring during pressing is thus likely to involve coupling or other reactions of radicals located on adjacent fibers, whereby interfiber covalent bonds are formed.

Similar content being viewed by others

References

Felby C, Nielsen BR, Olesen PO, Skibsted LH (1997a) Identification and quantification of radical reaction intermediates by electron spin resonance spectrometry of laccase-catalyzed oxidation of wood fibers from beech (Fagus sylvatica). Appl Microbiol Biotechnol 48:459–464

Felby C, Pedersen LS, Nielsen BR (1997b) Enhanced autoadhesion of wood fibers using phenol oxidases. Holzforschung 51:281–286

Hassingboe J, Lawther JM, Felby C (1998) Influence of extractives on enzymic catalyzed bonding of Norway spruce TMP fibers. In: 7th international conference biotechnology pulp and paper industry, pp A125-A128

Hon DN-S (1983) Mechanochemical reactions of lignocellulosic materials. J Appl Polym Sci (Appl Polym Symp) 37:461–481

Hüttermann A, Kharazipour A (1996) Enzymes as polymerisation catalysts. VTT Symp 163:143–148

Kharazipour A, Hüttermann A, Lüdemann H-D (1997) Enzymatic activation of wood fibres as a means for the production of wood composites. J Adhes Sci Technol 11:419–427

Kharazipour A, Bergmann K, Nonninger K, Hüttermann A (1998a) Properties of fibre boards obtained by activation of the middle lamella lignin of wood fibres with peroxidase and H2O2 before conventional pressing. J Adhes Sci Technol 11:1045–1053

Kharazipour A, Mai C, Hüttermann A (1998b) Polyphenoles for compounded materials. Polym Degrad Stab 59:237–243

Milstein O, Hüttermann A, Fründ R, Lüdemann H-D (1994) Enzymatic co-polymerization of lignin with low-molecular mass compounds. Appl Microbiol Biotechnol 40:760–767

Widsten P, Laine JE, Qvintus-Leino P, Tuominen S (2001) Effect of high-temperature fiberization on the chemical structure of softwood. J Wood Chem Technol 21:227–245

Widsten P, Laine JE, Qvintus-Leino P, Tuominen S (2002a) Effect of high-temperature defibration on the chemical structure of hardwood. Holzforschung 56:51–59

Widsten P, Laine JE, Tuominen S (2002b) Radical formation on laccase treatment of wood defibrated at high temperatures. Part 1. Studies with hardwood fibers. Nordic Pulp Pap Res J 17:139–146

Widsten P, Laine JE, Tuominen S (2002c) Radical formation on laccase treatment of wood defibrated at high temperatures. Part 2. Studies with softwood fibers. Cellul Chem Technol 36:161–172

Widsten P, Laine JE, Qvintus-Leino P, Tuominen S (2003) Effect of high defibration temperature on the properties of medium density fiberboard (MDF) made from laccase-treated hardwood fibers. J Adhes Sci Technol 17:67–78

Yaropolov AI, Skorobogatko OV, Vartanov SS, Varfolomeyev SD (1994) Laccase – properties, catalytic mechanism, and applicability. Appl Biochem Biotechnol 49:257–280

Zavarin E (1984) Activation of wood surface and nonconventional bonding. In: Rowell R (ed) The chemistry of solid wood. Advances in chemistry series no. 207, chap 10. American Chemical Society, Washington, D.C., pp 354–355

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Widsten, P., Tuominen, S., Qvintus-Leino, P. et al. The influence of high defibration temperature on the properties of medium-density fiberboard (MDF) made from laccase-treated softwood fibers. Wood Sci Technol 38, 521–528 (2004). https://doi.org/10.1007/s00226-003-0206-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-003-0206-4