Abstract

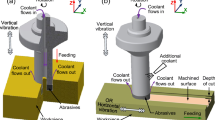

The superior properties make carbon fiber-reinforced plastic (CFRP) composites attractive in many applications. After CFRPs’ molding processes, additional machining processes are needed to produce final functional shapes with dimensional precision. Edge trimming is the primary process to cut the edge of CFRP composites. To reduce or further solve the problems in traditional machining processes, edge trimming of CFRP composites with rotary ultrasonic machining (RUM) has been proposed and conducted in this investigation. In RUM edge trimming processes, two different tool orientations (RUM edge trimming with tool end face and RUM edge trimming with tool side face) can be performed. The comparisons of machining performance and machined surface quality between these two different RUM edge trimming processes have been conducted. Smaller ultrasonic vibration amplitude in RUM using tool end face or larger ultrasonic vibration amplitude in RUM using tool side face produces smaller surface roughness. Lower feeding-directional cutting force, lower normal cutting force, and lower resultant force are generated in the process using tool side face. RUM using tool end face produces smaller surface roughness, smaller debris width, microcracking, flowed matrix on machined CFRP surfaces, etc.

Similar content being viewed by others

References

Jia Z, Su Y, Niu B, Zhang B, Wang F (2016) The interaction between the cutting force and induced sub-surface damage in machining of carbon fiber-reinforced plastics. J Reinf Plast Compos 35(9):712–726

Cong WL, Pei ZJ, Deines TW, Liu DF, Treadwell C (2013) Rotary ultrasonic machining of CFRP/Ti stacks using variable feedrate. Compos Part B 52:303–310

Dandekar CR, Shin YC (2012) Modeling of machining of composite materials: a review. Int J Mach Tools Manuf 57:102–121

Krishnaraj V, Prabukarthi A, Ramanathan A, Elanghovan N, Kumar MS, Zitoune R, Davim JP (2012) Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B 43(4):1791–1799

Karpat Y, Polat N (2013) Mechanistic force modeling for milling of carbon fiber reinforced polymers with double helix tools. CIRP Ann Manuf Technol 62(1):95–98

Haddad M, Zitoune R, Eyma F, Castanie B (2014) Study of the surface defects and dust generated during trimming of CFRP: influence of tool geometry, machining parameters and cutting speed range. Compos A: Appl Sci Manuf 66:142–154

Haddad M, Zitoune R, Bougherara H, Eyma F, Castanié B (2014) Study of trimming damages of CFRP structures in function of the machining processes and their impact on the mechanical behavior. Compos Part B 57:136–143

Cong WL, Ning FD (2015) Chapter 2 Rotary ultrasonic machining of CFRP composites. In: Davim JP (ed) Machinability of fibre-reinforced plastics. Walter de Gruyter GmbH & Co KG., Berlin, pp 31–81

Zhang JH, Zhao Y, Tian FQ, Zhang S, Guo LS (2015) Kinematics and experimental study on ultrasonic vibration-assisted micro end grinding of silica glass. Int J Adv Manuf Technol 78(9–12):1893–1904

Wang JJ, Zhang JF, Feng PF, Guo P (2017) Damage formation and suppression in rotary ultrasonic machining of hard and brittle materials: a critical review. Ceram Int 44:1227–1239

Wang JJ, Zhang CL, Feng PF, Zhang JF (2016) A model for prediction of subsurface damage in rotary ultrasonic face milling of optical K9 glass. Int J Adv Manuf Technol 83:347–355

Wang JJ, Feng PF, Zhang JF, Zhang CL, Pei ZJ (2016) Modeling the dependency of edge chip** size on the material properties and cutting force for rotary ultrasonic drilling of brittle materials. Int J Mach Tools Manuf 101:18–27

Wang JJ, Zha HT, Feng PF, Zhang JF (2016) On the mechanism of edge chip** reduction in rotary ultrasonic drilling: a novel experimental method. Precis Eng 44:231–235

Feng PF, Wang JJ, Zhang JF, Zheng JZ (2017) Drilling induced tearing defects in rotary ultrasonic machining of C/SiC composites. Ceram Int 43(1):791–799

Cong WL, Pei ZJ, Feng Q, Deines TW, Treadwell C (2012) Rotary ultrasonic machining of CFRP: a comparison with twist drilling. J Reinf Plast Compos 31(5):313–321

Ning FD, Cong WL, Pei ZJ, Treadwell C (2016) Rotary ultrasonic machining of CFRP: a comparison with grinding. Ultrasonics 66:125–132

Ning FD, Wang H, Cong WL, Fernando PKSC (2017) A mechanistic ultrasonic vibration amplitude model during rotary ultrasonic machining of CFRP composites. Ultrasonics 76:44–51

Cong WL, Pei ZJ, Sun X, Zhang CL (2014) Rotary ultrasonic machining of CFRP: a mechanistic predictive model for cutting force. Ultrasonics 54(2):663–675

Colligan K, Ramulu M (1992) The effect of edge trimming on composite surface plies. Manuf Rev 5(4):274–283

Janardhan P, Sheikh-Ahmad J, Cheraghi H (2006) Edge trimming of CFRP with diamond interlocking tools (No. 2006-01-3173). SAE Technical Paper

Sheikh-Ahmad J, Sridhar G (2002) Edge trimming of CFRP composites with diamond coated tools: edge wear and surface characteristics (No. 2002–01-1526). SAE Technical Paper

Ning FD, Cong WL, Hu YB, Wang H (2017) Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: effects of process parameters on tensile properties. J Compos Mater 51(4):451–462

Black JT, Kohser RA (2017) DeGarmo’s materials and processes in manufacturing. Wiley, Hoboken

Cong WL, Pei ZJ, Mohanty N, Van Vleet E, Treadwell C (2011) Vibration amplitude in rotary ultrasonic machining: a novel measurement method and effects of process variables. J Manuf Sci Eng 133(3):034501

Ning FD, Cong WL, Wang H, Hu YB, Hu ZL, Pei ZJ (2017) Surface grinding of CFRP composites with rotary ultrasonic machining: a mechanistic model on cutting force in the feed direction. Int J Adv Manuf Technol 92(1–4):1217–1229

Wang H, Ning FD, Hu YB, Fernando PKSC, Pei ZJ, Cong WL (2016) Surface grinding of carbon fiber–reinforced plastic composites using rotary ultrasonic machining: effects of tool variables. Adv Mech Eng 8(9):1687814016670284

Wang H, Cong WL, Ning FD, Hu YB (2018) A study on the effects of machining variables in surface grinding of CFRP composites using rotary ultrasonic machining. Int J Adv Manuf Technol 95(9–12):3651–3663. https://doi.org/10.1007/s00170-017-1468-6

Wang H, Hu YB, Ning FD, Li YZ, Zhang M, Cong WL, Smallwood S (2017) Surface grinding of CFRP composites using rotary ultrasonic machining: effects of ultrasonic power. In: ASME 2017 12th international manufacturing science and engineering conference, pp.V001T02A045-V001T02A045. doi:https://doi.org/10.1115/MSEC2017-2726

Wang H, Ning FD, Hu YB, Cong WL (2018) Surface grinding of CFRP composites using rotary ultrasonic machining: a comparison of workpiece machining orientations. Int J Adv Manuf Technol 95(5–8):2917–2930. https://doi.org/10.1007/s00170-017-1401-z

Jia Z, Fu R, Niu B, Qian B, Bai Y, Wang F (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tools Manuf 110:55–65

Denkena B, Köhler J, Hahmann D (2012) Grinding of steel-ceramic-composites. Int J Abras Technol 5(2):152–174

Ma JW, Jia ZY, Wang FJ, Ning FD (2014) Spindle speed selection for high-speed milling of titanium alloy curved surface. Mater Manuf Process 29(3):364–369

Wang H, Ning FD, Hu YB, Du DP, Cong WL (2017) Surface grinding of CFRP composites using rotary ultrasonic machining: design of experiment on cutting force, torque, and surface roughness. Int J Manuf Res 12(4):461–479. https://doi.org/10.1504/IJMR.2017.10008389

Bhaduri D, Soo SL, Novovic D, Aspinwall DK, Harden P, Waterhouse C, Lucas M (2013) Ultrasonic assisted creep feed grinding of Inconel 718. Proc CIRP 6:615–620

Hu YB, Wang H, Ning FD, Cong WL, Li YZ (2017) Surface grinding of optical BK7/K9 glass using rotary ultrasonic machining: an experimental study. In: ASME 2017 12th international manufacturing science and engineering conference. pp. V001T02A014-V001T02A014. doi:https://doi.org/10.1115/MSEC2017-2780

Acknowledgments

The work was supported by the National Science Foundation through award CMMI-1538381.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Ning, F., Hu, Y. et al. Edge trimming of carbon fiber-reinforced plastic composites using rotary ultrasonic machining: effects of tool orientations. Int J Adv Manuf Technol 98, 1641–1653 (2018). https://doi.org/10.1007/s00170-018-2355-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2355-5