Abstract

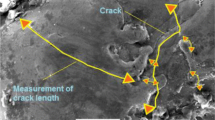

The performance of the produced parts in the electrical discharge machining (EDM) is strongly influenced by the final quality of surface. High thermal gradients in EDM process develop considerable changes in surface integrity of machined samples such as changing the chemical composition of the surface, micro cracks appearance, recast layer, residual stresses, and reduction in fatigue life and corrosion resistance. Ultrasonic-assisted EDM (USEDM) and powder-mixed dielectric EDM (PMEDM) are two techniques in improving EDM efficiency. This paper was an attempt to investigate the effects of USEDM, PMEDM, and powder-mixed dielectric USEDM (PM-USEDM) processes on main characteristics of the surface integrity such as surface roughness, micro cracks, heat-altered metal zone, and residual stress. Scanning electron microscopy (SEM) micrographs were used to analysis micro cracks and heat-altered metal zone, and nanoindentation method was utilized to measure the amount of residual stress of discharged surface. The results indicated that PMEDM process improved surface roughness as well, induced micro cracks in PM-USEDM were very low, and heat-altered metal layer was very thick in traditional EDM comparing to PM-USEDM process which was thinner. The results of the present study also confirmed that the amount of residual stress of ultrasonic-assisted process was partially in lower level and had different profile compared with traditional EDM and PMEDM process.

Similar content being viewed by others

References

Yadav V, Jain VK, Dixit PM (2002) Thermal stresses due to electrical discharge machining. Int J Mach Tools Manuf 42:877–888. doi:10.1016/S0890-6955(02)00029-9

Shabgard MR, Alenabi H (2015) Ultrasonic assisted electrical discharge machining of Ti–6Al–4V alloy. Mater Manuf Process 30(8):991–1000. doi:10.1080/10426914.2015.1004686

Dibitonto D, Eubank T, Patel MR, Barrufet MA (1989) Theoretical models of the electrical discharge machining process. I. A simple cathode erosion model. J Appl Phys 66:4095–4103. doi:10.1063/1.343994

Mamalis AG, Vosniakos GC, Vaxevanidis NM (1987) Macroscopic and microscopic phenomena of electro-discharge machined steel surfaces: an experimental investigation. J Mech Work Technol 15:335–356. doi:10.1016/0378-3804(87)90047-7

Lim LC, Lee LC, Wong YS, Lu HH (1991) Solidification microstructure of electro discharge machined surfaces of tool steels. Mater Sci Technol 7:239–249. doi:10.1179/026708391790183411

Sidhom H, Ghanem F, Amadou T, Gonzalez G, Braham C (2013) Effect of electro discharge machining (EDM) on the AISI316L SS white layer microstructure and corrosion resistance. Int J Adv Manuf Technol 65:141–153. doi:10.1007/s00170-012-4156-6

Biswas CK, Pradhan MK (2012) FEM of residual stress of EDMed surfaces. Adv Mater Res 383-390:872–876. doi:10.4028/www.scientific.net/AMR.383-390.872

Kremer D, Lebrun JL, Hosari B, Moisan A (1989) Effects of ultrasonic vibrations on the performances in EDM. Ann ClRP 38:199–202. doi:10.1016/S0007-8506(07)62684-5

Ekmekci B, Tekkaya AE, Erden A (2006) A semi-empirical approach for residual stresses in electric discharge machining (EDM). Int J Mach Tool Manuf 46:858–868. doi:10.1016/j.ijmachtools.2005.07.020

Mamalis G, Vosniakos GC, Vacevanidis NM (1988) Residual stress distribution and structural phenomena of high-strength steel surfaces due to EDM and ball-drop forming. Ann CIRP 37(1):531–535. doi:10.1016/S0007-8506(07)61694-1

Das S, Klotz M, Klocke F (2003) EDM simulation: finite element-based calculation of deformation, microstructure and residual stresses. J Mater Process Technol 142:434–451. doi:10.1016/S0924-0136(03)00624-1

Guu YH, Hocheng H, Chou CY, Deng CS (2003) Effect of electrical discharge machining on surface characteristics and machining damage of AISI D2 tool steel. Mater Sci Eng A358:37–43. doi:10.1016/S0921-5093(03)00272-7

Ghanem F, Braham C, Fitzpatrick ME, Sidhom H (2002) Effect of near-surface residual stress and microstructure modification from machining on the fatigue endurance of a tool steel. J Mater Eng Perform 11(6):631–639

Ghanem F, Fredj NB, Sidhom H, Braham C (2011) Effects of finishing processes on the fatigue life improvements of electro-machined surfaces of tool steel. Int J Adv Manuf Technol 52:583–595. doi:10.1007/s00170-010-2751-y

Casas B, Torres Y, Llanes L (2006) Fracture and fatigue behavior of electrical-discharge machined cemented carbides. Int J Refract Met Hard Mater 24:162–167. doi:10.1016/j.ijrmhm.2005.04.007

Rebelo JC, Dias AM, Kremer D, Lebrun JL (1998) Influence of EDM pulse energy on the surface integrity of martensitic steels. J Mater Process Technol 84:90–96. doi:10.1016/S0924-0136(98)00082-X

Yang X, Han X, Zhou F, Kunieda M (2013) Molecular dynamics simulation of residual stress generated in EDM. Procedia CIRP 6:433–438. doi:10.1016/j.procir.2013.03.037

Lütjering G, Williams JC (2007) Titanium, 2nd edition, Springer, Verlag-Berlin Heidelberg

Matthew J, Donachie Jr (2000) Titanium: a technical guide, 2nd edn, ASM International

Zhu LN, Xu BS, Wang HD, Wang CB (2010) Measurement of residual stress in quenched 1045 steel by the nanoindentation method. Mater Charact 61:1359–1362. doi:10.1016/j.matchar.2010.09.006

Anthony C, Cripps F (2011) Nanoindentation, Third Edition, Springer-Verlag New York

Lee YH, Kwon D (2004) Estimation of biaxial surface stress by instrumented indentation with sharp indenters. Acta Mater 52(6):1555–1563. doi:10.1016/j.actamat.2003.12.006

Suresh S, Giannakopoulos AE (1999) A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater 46(16):5755–5767. doi:10.1016/S1359-6454(98)00226-2

Murthy VSR, Philip PK (1987) Pulse train analysis in ultrasonic assisted EDM. Int J Mach Tool Manuf 27(4):469–477. doi:10.1016/S0890-6955(87)80019-6

Takeshi H, Masanori H, Toshiaki O (2002) Mechanical vibration assisted plasma etching for etch rate and anisotropy improvement. Precis Eng 26(4):442–447. doi:10.1016/S0141-6359(02)00151-4

Abdullah A, Shabgard MR (2008) Effect of ultrasonic vibration of tool on electrical discharge machining of cemented tungsten carbide (WC-Co). Int J Adv Manuf Technol 38:1137–1147. doi:10.1007/s00170-007-1168-8

Shabgard MR, Kakolvand H, Seyedzavvar M, Shotorbani RM (2011) Ultrasonic assisted EDM: effect of the workpiece vibration in the machining characteristics of FW4 Welded Metal. Front Mech Eng 6(4):419–428. doi:10.1007/s11465-011-0246-7

Prihandana GS, Mahardika M, Hamdi M, Wong YS, Mitsui K (2009) Effect of micro-powder suspension and ultrasonic vibration of dielectric fluid in micro-EDM processes-Taguchi approach. Int J Mach Tool Manuf 49:1035–1041. doi:10.1016/j.ijmachtools.2009.06.014

Prihandana GS, Mahardika M, Hamdi M, Wong YS, Mitsui K (2011) Accuracy improvement in nanographite powder-suspended dielectric fluid for micro-electrical discharge machining processes. Int J Adv Manuf Technol 56:143–149. doi:10.1007/s00170-011-3152-6

Shabgard MR, Khosrozadeh B, Sadizadeh B, Kakoulvand H (2013) Comparative study of the effect of ultrasonic vibration of work piece in the electrical discharge machining (EDM). Modares Mech Eng 13(12):48–55 (in Persian)

Kumar H (2015) Development of mirror like surface characteristics using nano powder mixed electric discharge machining (NPMEDM). Int J Adv Manuf Technol 76(1):105–113. doi:10.1007/s00170-014-5965-6

Wang Y, Zhao F, Liu Y (2008) Behaviors of suspended powder in powder mixed EDM. Key Eng Mater 375-376:36–41. doi:10.4028/www.scientific.net/KEM.375-376.36

Lin YC, Yan BH, Chang YS (2000) Machining characteristics of titanium alloy (Ti-6Al-4V) using a combination process of EDM with USM. J Mater Process Technol 104:171–177. doi:10.1016/S0924-0136(00)00539-2

Ekmekci B (2007) Residual stresses and white layer in electric discharge machining (EDM). Appl Surf Sci 253:9234–9240. doi:10.1016/j.apsusc.2007.05.078

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khosrozadeh, B., Shabgard, M. Effects of hybrid electrical discharge machining processes on surface integrity and residual stresses of Ti-6Al-4V titanium alloy. Int J Adv Manuf Technol 93, 1999–2011 (2017). https://doi.org/10.1007/s00170-017-0601-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0601-x