Abstract

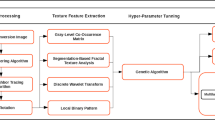

Cutting and extruding processing technology for ceramics based on the edge-chip** effect is a non-traditional rough machining method for engineering ceramics. A set of new methods for evaluating unconventional rough surfaces of such ceramics was developed by using grey-level co-occurrence matrix (GLCM) and a neural network (NN). The influences of three parameters including step size, greyscale quantisation and direction on the GLCM were investigated to measure the morphology of the machined surface of Si3N4 ceramic by using a GLCM with suitable such parameters. Based on a generalised regression network, a prediction model for the textural features of sintered Si3N4 ceramic surfaces was established with multiple processing parameters. Moreover, a competitive layer network was used to sort the roughness grades of the machined surface. The division and cooperation of the generalised regression network and competitive network are able to preferably identify and predict the roughness of the machined surface without contact.

Similar content being viewed by others

References

Malzbender J, Steinbrech RW (2008) Threshold fracture stress of thin ceramic components. J Eur Ceram Soc 28:247–252

Gadelmawla ES (2004) A vision system for surface roughness characterization using the gray level co-occurrence matrix. NDT&E Int 37:577–588

Ulaby FT, Kouyate F, Brisco B (1986) Textural information in SAR images. IEEE T Geosci Remote 24:235–245

Wang L, Tian XL, Wang WL (2015) Cutting and extruding processing technology for ceramics based on edge-chip** effect. Int J Mach Tools Manuf 84:673–678

Fernando RS, William RS, Helio P (2013) Multi-scale gray level co-occurrence matrices for texture description. Neurocomputing 120:336–345

Mehmet EY, Levent BK (2012) Surface creation on unstructured point sets using neural networks. Comput Aided Des 44:644–656

Guo RP, Tao ZS (2013) A study of neural network for surface characteristics in-process optical measurement. Optik 124:2821–2824

Tang XJ, Tian XL, Wang WL (2013) Study on fracture regulars and mechanisms of edge chip** for engineering ceramics based on energy. J Synth Cryst 42:1–4

Zhang Y, James JWL, Ramanathan S (2013) Edge chip** and flexural resistance of monolithic ceramics. Dent Mater 29:1201–1208

Mohajerani A, Spelt JK (2011) Edge chip** of borosilicate glass by low velocity impact of sherical indenters. Mech Mater 43:671–683

Mohajerani A, Spelt JK (2010) Edge chip** of borosilicate glass by blunt indentation. Mech Mater 42:1064–1080

Yang B, Shen X, Lei S (2009) Mechanisms of edge chip** in laser-assisted milling of silicon nitride ceramics. Int J Mach Tool Manuf 49:344–350

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Tian, X., Wang, W. et al. Evaluation of machined surface quality of Si3N4 ceramics based on neural network and grey-level co-occurrence matrix. Int J Adv Manuf Technol 89, 1661–1668 (2017). https://doi.org/10.1007/s00170-016-9191-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9191-2