Abstract

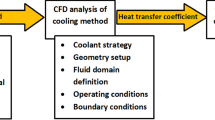

Cutting fluid is the most common method to control the cutting temperature. However, it is usually harmful to the environment and personal health. Near-dry cutting could be an effective substitute of cutting fluid. Most researchers focus on the lubrication during near-dry cutting processes. Actually, the cooling ability of near-dry cutting is very important for the control of cutting temperature and effectiveness of coolant. In this study, heat transfer coefficients (HTCs) of different cooling processes, including nature cooling, compressed air cooling, compressed cold air cooling, minimal quantity lubrication (MQL) cooling, and atomizing water cooling, have been estimated. Surface temperature, temperature of coolant carrier, and air velocity of coolant carrier have a great effect on the cooling ability of near-dry cutting system. The finite element method (FEM) is employed to simulate the cooling process and modify the estimated heat transfer coefficients. It is found that HTC is from 9.3 to 53.9 W/m2/°C with different surface temperatures in nature cooling. HTC increases with the increase of surface temperature. HTC is from 48.1 to 346.0 W/m2/°C with different air velocity and surface temperature in compressed air cooling. HTC has an increased trend with the increase of air velocity. HTC is from 52.6 to 405.6 W/m2/°C with different air velocities and surface temperatures in compressed cold air cooling. Lower air temperature increases HTC by 10∼20 %. HTC is from 96.5 to 718.7 W/m2/°C with different oil quantities and surface temperatures in MQL cooling. HTC increases with the increase of oil quantity of MQL. As a comparison, HTC is from 133.7 to 519.6 W/m2/°C with different water quantities and surface temperatures in atomizing water lubrication (AWL) cooling. HTC of AWL is much lower than that of MQL in the same condition, especially when the surface temperature is high. The boiling point of water is much lower than oil; subsequently, less water mist arrives at the cooled surface, so less heat is removed with AWL cooling than that with MQL cooling in the same condition. HTC is from 282.1 to 1890.3 W/m2/°C with different oil quantities and surface temperatures in cold-air MQL cooling. Lower carrier temperature increases the HTC greatly, even increases the HTC by 150 % when the surface temperature is up to 700 °C. The reason is that the coolant prevents high-temperature deterioration before the coolant arrives at a cooled surface.

Similar content being viewed by others

References

Su Y, He N, Li L, Li XL (2006) An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of Ti-6Al-4V. Wear 261:760–766. doi:10.1016/j.wear.2006.01.013

Wakabayashi T, Suda S, Inasaki I, Terasaka K, Musha Y, Toda Y (2007) Tribological action and cutting performance of MQL media in machining of aluminum. CIRP Ann Manuf Technol 56:97–100. doi:10.1016/j.cirp.2007.05.025

Zhang Y, Jun MBG (2013) Mixed jet of independently atomized water and oil sprays as cutting fluids in micro-milling. Manuf Lett 1:13–16. doi:10.1016/j.mfglet.2013.08.003

Yokogawa K, Yokogawa M, Okumura S (1998) Cooling air grinding and cutting technology. Tool Eng 42:57–62

Hong SYDY (2001) Cooling approaches and cutting temperatures in cryogenic machining of Ti-6Al-4V. Int J Mach Tools Manuf 41:1417–1437

Jiang F, Li J, Yan L, Sun J, Zhang S (2010) Optimizing end-milling parameters for surface roughness under different cooling/lubrication conditions. Int J Adv Manuf Technol 51:841–851. doi:10.1007/s00170-010-2680-9

Hadad M, Sadeghi B (2013) Minimum quantity lubrication-MQL turning of AISI 4140 steel alloy. J Clean Prod 54:332–343. doi:10.1016/j.jclepro.2013.05.011

Astakhov VP, Joksch S.(2012) Metalworking fluids (Mwfs) for cutting and grinding: fundamentals and recent advances

Yamazaki T, Miki K, Sato U (2003) Cooling air cutting of Ti-6Al-4V alloy. J Jpn Inst Light Metals 53:416–420

Wang S, Clarens AF (2013) Analytical model of metalworking fluid penetration into the flank contact zone in orthogonal cutting. J Manuf Process 15:41–50. doi:10.1016/j.jmapro.2012.09.015

Ueda T, Hosokawa A, Yamada K (2006) Effect of oil mist on tool temperature in cutting. ASME J Manuf Sci Eng 128:130–135

Hadad M, Sadeghi B (2012) Thermal analysis of minimum quantity lubrication-MQL grinding process. Int J Mach Tools Manuf 63:1–15. doi:10.1016/j.ijmachtools.2012.07.003

Atlati S, Haddag B, Nouari M, Zenasni M (2014) Thermomechanical modelling of the tool–work material interface in machining and its implementation using the ABAQUS VUINTER subroutine. Int J Mech Sci 87:102–117. doi:10.1016/j.ijmecsci.2014.05.034

Ceretti E, Filice L, Umbrello D, Micari F (2007) ALE simulation of orthogonal cutting: a new approach to model heat transfer phenomena at the tool-chip interface. CIRP Ann Manuf Technol 56:69–72. doi:10.1016/j.cirp.2007.05.019

Brandão LC, Coelho RT, Malavolta AT (2010) Experimental and theoretical study on workpiece temperature when tap** hardened AISI H13 using different cooling systems. J Braz Soc Mech Sci Eng 32:154–159

Brandao LC, Coelho RT, Lauro CH (2011) Contribution to dynamic characteristics of the cutting temperature in the drilling process considering one dimension heat flow. Appl Therm Eng 31:3806–3813. doi:10.1016/j.applthermaleng.2011.07.024

Luchesi VM, Coelho RT (2012) Experimental investigations of heat transfer coefficients of cutting fluids in metal cutting processes: analysis of workpiece phenomena in a given case study. Proc Inst Mech Eng 226

Kops L, Arenson M (1999) Determination of convective cooling conditions in turning. CIRP Ann Manuf Technol 48:47–52. doi:10.1016/S0007-8506(07)63129-1

Jiang F, Li J, Sun J, Al E (2010) Estimation of heat transfer coefficients in dry and cold-air cutting. Adv Mater Res 126-128:341–346

Umbrello D, Filice L, Rizzuti S, Micari F (2007) On the evaluation of the global heat transfer coefficient in cutting. Int J Mach Tools Manuf 47:1738–1743. doi:10.1016/j.ijmachtools.2006.12.002

Barrios ANS, Silva JBC, Rodrigues AR, Coelho RT, Braghini Junior A, Matsumoto H (2014) Modeling heat transfer in die milling. Appl Therm Eng 64:108–116. doi:10.1016/j.applthermaleng.2013.12.015

Lincoln Cardoso Brandão RTCA (2008) Experimental and theoretical study of workpiece temperature when end milling hardened steels using (TiAl)N-coated and PcBN-tipped tools. J Mater Process Technol 199:234–244

Cheng G, Han F, Feng Z (2007) Experimental determination of convective heat transfer coefficient in WEDM. Int J Mach Tools Manuf 47:1744–1751. doi:10.1016/j.ijmachtools.2006.12.003

Lin J, Liu CY (2001) Measurement of cutting tool temperature by an infrared pyrometer. Meas Sci Technol 1243–1249

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, F., Zhang, T. & Yan, L. Estimation of temperature-dependent heat transfer coefficients in near-dry cutting. Int J Adv Manuf Technol 86, 1207–1218 (2016). https://doi.org/10.1007/s00170-015-8293-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8293-6