Abstract

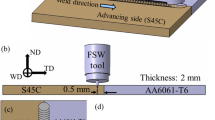

One type of advanced high-strength steel, transformation-induced plasticity (TRIP) 780 steel, has been successfully welded to aluminum alloy Al 6061-T6 using friction stir welding (FSW) technique. The major Al-Fe interface in the steel side has been analyzed in detail under various welding conditions, where a thin layer of intermetallic compound (IMC) with a thickness of less than 1 μm can be generally observed and the composition was identified to be either FeAl or Fe3Al. This thin IMC layer can be shown to be beneficial for joint strength. Optical microscopy and scanning electron microscopy showed the weld nugget was distributed with sheared-off steel fragments encompassed IMC layers or simply IMC particles. Finally, a stirred-over steel strip embedded in the aluminum matrix was revealed, which would determine the failure mode and is crucial to joint quality based on tensile test results.

Similar content being viewed by others

References

Sakiyama T, Murayama G, Naito Y, Saita K, Oikawa YMH, Nose T (2013) Dissimilar metal joining technologies for steel sheet and aluminum alloy sheet in auto body. Nippon steel technical report

Ogura T, Saito Y, Nishida T, Nishida H, Yoshida T, Omichi N, Fujimoto M, Hirose A (2012) Partitioning evaluation of mechanical properties and the interfacial microstructure in a friction stir welded aluminum alloy/stainless steel lap joint. Scr Mater

Das H, Basak S, Das G, Pal TK (2013) Influence of energy induced from processing parameters on the mechanical properties of friction stir welded lap joint of aluminum to coated steel sheet. Int J Adv Manuf Technol 64(9–12):1653–1661

Movahedi M, Kokabi AH, Seyed Reihani SM, Cheng WJ, Wang CJ (2013) Effect of annealing treatment on joint strength of aluminum/steel friction stir lap weld. Mater Des 44(0):487–492. doi:10.1016/j.matdes.2012.08.028

Movahedi M, Kokabi A, Reihani S, Najafi H (2012) Effect of tool travel and rotation speeds on weld zone defects and joint strength of aluminium steel lap joints made by friction stir welding. Sci Technol Weld Join 17(2):162–167

Uematsu Y, Kakiuchi T, Tozaki Y, Ko** H (2012) Comparative study of fatigue behaviour in dissimilar Al alloy/steel and Mg alloy/steel friction stir spot welds fabricated by scroll grooved tool without probe. Sci Technol Weld Join 17(5):348–356

Flores OV, Kennedy C, Murr L, Brown D, Pappu S, Nowak BM, McClure J (1998) Microstructural issues in a friction-stir-welded aluminum alloy. Scr Mater 38(5):703–708

Uzun H, Dalle Donne C, Argagnotto A, Ghidini T, Gambaro C (2005) Friction stir welding of dissimilar Al 6013-T4 To X5CrNi18-10 stainless steel. Mater Des 26(1):41–46. doi:10.1016/j.matdes.2004.04.002

Tanaka T, Morishige T, Hirata T (2009) Comprehensive analysis of joint strength for dissimilar friction stir welds of mild steel to aluminum alloys. Scr Mater 61(7):756–759. doi:10.1016/j.scriptamat.2009.06.022

Liu X, Lan S, Ni J (2015) Experimental investigation on joining dissimilar aluminum alloy 6061 to TRIP 780/800 steel through friction stir welding. J Eng Mater Technol 137(4), 041001-1-11. doi:10.1115/1.4030480

Lee W-B, Schmuecker M, Mercardo UA, Biallas G, Jung S-B (2006) Interfacial reaction in steel–aluminum joints made by friction stir welding. Scr Mater 55(4):355–358. doi:10.1016/j.scriptamat.2006.04.028

Ghosh M, Kar A, Kumar K, Kailas S (2012) Structural characterisation of reaction zone for friction stir welded aluminium-stainless steel joint. Mater Technol: Adv Perform Mater 27(2):169–172

Chen CM, Kovacevic R (2004) Joining of Al 6061 alloy to AISI 1018 steel by combined effects of fusion and solid state welding. Int J Mach Tools Manuf 44(11):1205–1214. doi:10.1016/j.ijmachtools.2004.03.011

Lee CY, Choi DH, Yeon YM, Jung SB (2009) Dissimilar friction stir spot welding of low carbon steel and Al-Mg alloy by formation of IMCs. Sci Technol Weld Join 14(3):216–220

Watanabe T, Takayama H, Yanagisawa A (2006) Joining of aluminum alloy to steel by friction stir welding. J Mater Process Technol 178(1–3):342–349. doi:10.1016/j.jmatprotec.2006.04.117

Kimapong K, Watanabe T (2005) Effect of welding process parameters on mechanical property of FSW lap joint between aluminum alloy and steel. Mater Trans 46(10):2211–2217

Chen Y, Komazaki T, Tsumura T, Nakata K (2008) Role of zinc coat in friction stir lap welding Al and zinc coated steel. Mater Sci Technol 24(1):33–39

Chen YC, Komazaki T, Kim YG, Tsumura T, Nakata K (2008) Interface microstructure study of friction stir lap joint of AC4C cast aluminum alloy and zinc-coated steel. Mater Chem Phys 111(2–3):375–380. doi:10.1016/j.matchemphys.2008.04.038

Kuziak R, Kawalla R, Waengler S (2008) Advanced high strength steels for automotive industry. Arch Civ Mech Eng 8(2):103–117

Da Silva A, Aldanondo E, Alvarez P, Arruti E, Echeverria A (2010) Friction stir spot welding of AA 1050 Al alloy and hot stamped boron steel (22MnB5). Sci Technol Weld Join 15(8):682–687

Chung Y, Fujii H, Ueji R, Tsuji N (2010) Friction stir welding of high carbon steel with excellent toughness and ductility. Scr Mater 63(2):223–226

Ikeda R, Matsushita M, Fujii H, Chung YD, Kitani Y, Ono M (2011) Development of friction stir welding of high strength steel sheet. Sci Technol Weld Join 16(2):181–187. doi:10.1179/1362171810y.0000000026

Jafarzadegan M, Feng A, Abdollah-zadeh A, Saeid T, Shen J, Assadi H (2012) Microstructural characterization in dissimilar friction stir welding between 304 stainless steel and st37 steel. Mater Charact

Barnes S, Bhatti A, Steuwer A, Johnson R, Altenkirch J, Withers P (2012) Friction stir welding in HSLA-65 steel: part I. Influence of weld speed and tool material on microstructural development. Metall Mater Trans A 43(7):2342–2355

Ohashi R, Fujimoto M, Mironov S, Sato Y, Kokawa H (2009) Effect of contamination on microstructure in friction stir spot welded DP590 steel. Sci Technol Weld Join 14(3):221–227

Miles M, Pew J, Nelson T, Li M (2006) Comparison of formability of friction stir welded and laser welded dual phase 590 steel sheets. Sci Technol Weld Join 11(4):384–388

Miles M, Nelson T, Steel R, Olsen E, Gallagher M (2009) Effect of friction stir welding conditions on properties and microstructures of high strength automotive steel. Sci Technol Weld Join 14(3):228–232

Park SHC, Sato YS, Kokawa H, Okamoto K, Hirano S, Inagaki M (2009) Boride formation induced by pcBN tool wear in friction-stir-welded stainless steels. Metall Mater Trans A 40(3):625–636

Rathod M, Kutsuna M (2004) Joining of aluminum alloy 5052 and low-carbon steel by laser roll welding. Weld J 83(1):16

Bouché K, Barbier F, Coulet A (1998) Intermetallic compound layer growth between solid iron and molten aluminium. Mater Sci Eng A 249(1–2):167–175. doi:10.1016/S0921-5093(98)00573-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lan, S., Liu, X. & Ni, J. Microstructural evolution during friction stir welding of dissimilar aluminum alloy to advanced high-strength steel. Int J Adv Manuf Technol 82, 2183–2193 (2016). https://doi.org/10.1007/s00170-015-7531-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7531-2