Abstract

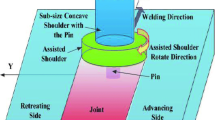

A 3D model is developed for numerical analysis for heat generation, temperature field, and material flow in reverse dual-rotation friction stir welding (RDR-FSW) process. The reverse rotation of the assisted shoulder and the tool pin is considered to determine the heat generation rate. Friction heat, plastic deformation heat, and their partition coefficients are analyzed. Due to the tool pin and assisted shoulder being separated and reversely rotated independently, the temperature difference between the advancing and retreating sides is weakened. The reverse material flow is beneficial to the uniformity of both the temperature and microstructure at the advancing and retreating sides. The calculated temperature profiles agree well with the corresponding experimentally measured values.

Similar content being viewed by others

References

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50(1):1–78

Nandan R, Debroy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding-process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

DebRoy T, Bhadeshia H (2010) Friction stir welding of dissimilar alloys—a perspective. Sci Technol Weld Join 15(4):266–270

Vilaça P, Thomas W (2012) Friction stir welding technology. Adv Struct Mater 8:85–124

Chen C, Kovacevic R (2004) Thermomechanical modeling and force analysis of friction stir welding by the finite element method. J Mech Eng Sci 218(5):509–519

Zimmer S, Langlois L, Laye J, Bigot R (2010) Experimental investigation of the influence of the FSW plunge processing parameters on the maximum generated force and torque. Int J Adv Manuf Technol 47(1–4):201–215

Li JQ, Liu HJ (2013) Effects of welding speed on microstructures and mechanical properties of AA2219-T6 welded by the reverse dual-rotation friction stir welding. Int J Adv Manuf Technol 68(9–12):2071–2083

Thomas WM, Norris IM, Staines DG, Watts ER (2005) Friction stir welding—process developments and variant techniques. The SME Summit 2005, Oconomowoc

Li JQ, Liu HJ (2013) Characteristics of the reverse dual-rotation friction stir welding conducted on 2219-T6 aluminum alloy. Mater Des 45:148–154

Gök K, Aydin M (2013) Investigations of friction stir welding process using finite element method. Int J Adv Manuf Technol 68(1–4):775–780

Zhang Z, Zhang HW (2007) Material behaviors and mechanical features in friction stir welding process. Int J Adv Manuf Technol 35(1–2):86–100

Nandan R, Roy GG, Lienert TJ, DebRoy T (2006) Numerical modelling of 3D plastic flow and heat transfer during friction stir welding of stainless steel. Sci Technol Weld Join 11(5):526–537

Prasanna P, Rao BS, Rao GKM (2010) Finite element modeling for maximum temperature in friction stir welding and its validation. Int J Adv Manuf Technol 51(9–12):925–933

Colegrove PA, Shercliff HR, Zettler R (2007) Model for predicting heat generation and temperature in friction stir welding from the material properties. Sci Technol Weld Join 12(4):284–297

Neto DM, Neto P (2013) Numerical modeling of friction stir welding process: a literature review. Int J Adv Manuf Technol 65(1-4):115–126

Nandan R, Roy GG, DebRoy T (2006) Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall Mater Trans A 37(4):1247–1259

Zhang Z, Zhang HW (2014) Solid mechanics-based Eulerian model of friction stir welding. Int J Adv Manuf Technol. doi:10.1007/s00170-014-5789-4

Arora A, De A, DebRoy T (2011) Toward optimum friction stir welding tool shoulder diameter. Scr Mater 64(1):9–12

Wu CS, Zhang WB, Shi L, Chen MA (2012) Visualization and simulation of the plastic material flow in friction stir welding of aluminium alloy 2024 plates. Trans Nonferrous Metals Soc China 22(6):1445–1451

Al-Badour F, Merah N, Shuaib A, Bazoune A (2014) Thermo-mechanical finite element model of friction stir welding of dissimilar alloys. Int J Adv Manuf Technol. doi:10.1007/s00170-014-5680-3

Nandan R, Roy GG, Lienert TJ, DebRoy T (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883–895

Perzyna P, Wojno W (1966) On the constitutive equations of elastic/viscoplastic materials at finite strain. Arch Appl Mech 18:85

Seidel TU, Reynolds AP (2001) Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall Mater Trans A 32(11):2879–2884

Sheppard T, Wright DS (1979) Determination of flow stress: part 1 constitutive equation for aluminum alloys at elevated temperatures. Metals Technol 6(1):215–223

Sheppard T, Jackson A (1997) Constitutive equations for use in prediction of flow stress during extrusion of aluminum alloys. Mater Sci Technol 13(3):203–209

Cho HH, Hong ST, Roh JH, Choi HS, Kang SH, Steel RJ, Han HN (2013) Three-dimensional numerical and experimental investigation on friction stir welding processes of ferritic stainless steel. Acta Mater 61(7):2649–2661

Awang M, Mucino VH, Feng Z, David SA (2005) Thermo-mechanical modeling of friction stir spot welding (FSSW) process: use of an explicit adaptive meshing scheme, Proceedings of the SAE 2005 World Congress & Exhibition, 2005 April 11–14

Schmidt H, Hattel J (2005) Modelling heat flow around tool probe in friction stir welding. Sci Technol Weld Join 10(2):176–186

Lienert TJ, Stellwag JWL, Grimmett BB, Warke RW (2003) Friction stir welding studies on mild steel. Weld J 82(1):1s–9s

Mehta M, Chatterjee K, De A (2013) Monitoring torque and traverse force in friction stir welding from input electrical signatures of driving motors. Sci Technol Weld Join 18(3):191–197

Patankar SV (1980) Numerical heat transfer and fluid flow. Hemisphere, Washington

Schmidt H, Dickerson TL, Hattel J (2006) Material flow in butt friction stir welds in AA2024-T3. Acta Mater 54(4):1199–1209

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, L., Wu, C.S. & Liu, H.J. Numerical analysis of heat generation and temperature field in reverse dual-rotation friction stir welding. Int J Adv Manuf Technol 74, 319–334 (2014). https://doi.org/10.1007/s00170-014-5967-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5967-4