Abstract

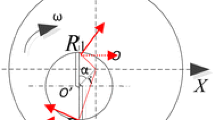

Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing effect in the tool run-out. Therefore, this needed to be taken into account to design a model for reliably predicting the cutting forces in these processes. In this paper, a study of the tool deflection phenomenon was carried out by applying the principles of elasticity of materials to the situation of a tool under a distributed force along its edge. The contribution of this study consisted of considering a variable deflection along the length of the edge, which has not been taken into account in previous models. A new methodology of obtaining the rigidity, based on experimental data, was applied to two specific types of mills by using their geometry. With this model, a linear equations system that allows the prediction of cutting forces was obtained. These predictions, which were calculated with a low computational cost, can be used in monitoring systems and adaptive control of the process for the prevention of tool failure.

Similar content being viewed by others

References

Nakamoto K, Ishida T, Kitamura N, Takeuchi Y (2011) Fabrication of microinducer by 5-axis control ultraprecision micromilling. CIRP Ann Manuf Technol 60(1):407–410

Brousseau E, Dimov S, Pham D (2010) Some recent advances in multi-material micro-and nano-manufacturing. Int J Adv Manuf Technol 47:161–180

Rodriguez P, Perez H, Labarga J, Vizan A (2008) Research on tool life in micro-end-milling as related to workpiece quality criteria. Proceedings of the Early Technical Career Conference, Miami, pp 163–165

DeVor RE, Kline W, Zdeblick WJ (1980) A mechanistic model for the force system in end milling with application to machining airframe structures. 8th North Am Manuf Res Conf 8:297–303

Smith S, Tlusty J (1991) An overview of modeling and simulation of the milling process. J Eng Ind 113:169–175

Carboloy Systems Department (1980) Milling handbook of high-efficiency metal cutting. Published by General Electric Company, London

Tlusty P, MacNeil J (1975) Dynamics of cutting forces in end milling. CIRP Ann 24:21–25

Tlusty J (1985) Machine dynamics. In: King RI (ed) Handbook of high-speed machining technology. Chapman and Hall, New York

Sutherland JW, DeVor RE (1986) Improved method for cutting force and surface error prediction in flexible end milling systems. J Eng Ind 108:269–279

Mamedov A, Layegh SE, Lazoglu KI (2013) Machining forces and tool deflections in micro milling. Procedia CIRP 8:147–151

Tlusty J, Ismail F (1983) Special aspects of chatter in milling. Trans ASME 105:24

Rodríguez P, Labarga JE (2013) A new model for the prediction of cutting forces in micro-end-milling operations. J Mater Process Technol 213:261–268

Budak E, Altintas Y, Armarego EJA (1996) Prediction of milling force coefficients from orthogonal cutting data. J Manuf Sci Eng Trans ASME 118:216–224

Cardoso P, Davim JP (2012) A brief review on micromachining of materials. Rev Adv Mater Sci 30:98–102

Davim JP (2008) Machining: fundamentals and recent advances, Springer-Verlag, London Limited

Nash WA (1998) Schaum’s outline of theory and problems of strength of materials. Schaum’s Outline Series, McGraw Hill

Davim JP, Jackson MJ (eds) (2010) Frontmatter, in Nano and Micromachining, ISTE, London, UK. doi:10.1002/9780470611807.fmatter

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33:402–407

Kim CJ, Mayor JR (2004) A static model of chip formation in microscale milling. J Manuf Sci Eng 126:710

Câmara MA, Rubio JCC, Abrão AM, Davim JP (2012) State of the art on micromilling of materials, a review. J Mater Sci Technol 28:673–685

Pérez H, Vizán A, Hernandez JC, Guzmán M (2007) Estimation of cutting forces in micromilling through the determination of specific cutting pressures. J Mater Process Technol 190:18–22

Özel T, Liu X, Dhanorker A (2007) Modelling and simulation of micro-milling process. In 4th International Conference and Exhibition on Design and Production of Machines and Dies/Molds pp 21–23

Kuram E, Ozcelik B (2013) Multi-objective optimization using Taguchi based grey relational analysis for micro-milling of Al 7075 material with ball nose end mill. Measurement 46:1849–1864

Bissacco G, Hansen HN, Slunsky J (2008) Modelling the cutting edge radius size effect for force prediction in micro milling. CIRP Ann Manuf Technol 57:113–116

Bao WY, Tansel IN (2000) Modeling micro-end-milling operations. Part I: analytical cutting force model. Int J Mach Tools Manuf 40:2155–2173

Jaffery SI, Driver N, Mativenga PT (2010) Analysis of process parameters in the micromachining of Ti-6Al-4V alloy. In Proceedings of the 36th International MATADOR Conference. Springer, London, pp 239–242

Mian AJ, Driver N, Mativenga PT (2011) Identification of factors that dominate size effect in micro-machining. Int J Mach Tools Manuf 51:383–394

Newby G, Venkatachalam S, Liang SY (2007) Empirical analysis of cutting force constants in micro-end-milling operations. J Mater Process Technol 192–193:41–47

Dornfeld D, Min S, Takeuchi Y (2006) Recent advances in mechanical micromachining. CIRP Ann Manuf Technol 55:745–768

Mian A, Driver N, Mativenga P (2011) Estimation of minimum chip thickness in micro-milling using acoustic emission. Proc Inst Mech Eng Pt B: J Eng Manuf 225:1535–1551

Vogler MP, Devor RE, Kapoor SG (2004) On the modeling and analysis of machining performance in micro-end-milling: II. Cutting force prediction. J Manuf Sci Eng 126:695

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodríguez, P., Labarga, J.E. Tool deflection model for micromilling processes. Int J Adv Manuf Technol 76, 199–207 (2015). https://doi.org/10.1007/s00170-014-5890-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5890-8