Abstract

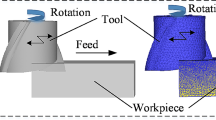

Because it reduces forces and temperatures, vibration-assisted grinding has the potential to improve the feasibility of dry grinding. This paper presents an experimental study of force and temperature effects in dry and wet grinding at vibration frequencies below ultrasonic. Based on a moving line heat source model, heat flux quantities were estimated from subsurface temperature measurements. Reductions in force of up to 30 % were observed for dry grinding with 2,360 Hz vibration assistance. For the same condition, heat flux into the workpiece reduced by 42 %. The paper presents evidence that vibration assistance has a beneficial effect on the convective heat transfer rate.

Similar content being viewed by others

References

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32:153–172

Colwell L (1956) Effects of high frequency vibrations in grinding. Trans ASME 124-131

Peng Y, Wu YB, Liang ZQ, Guo YB, Lin X (2011) An experimental study of ultrasonic vibration-assisted grinding of polysilicon using two-dimensional vertical workpiece vibration. Int J Adv Manuf Tech 54:941–947

Spur G, Uhlmann E, Holl S (2006) Ultrasonic machining of ceramics. In: Marinescu ID (ed) Handbook of advanced ceramic machining. CRC Press, Boca Raton, FL

Warnecke G, Zapp M (1995) Ultrasonic superimposed grinding of advanced ceramics, SME Tech Paper–MR95-169, Int Mach and Grind Conf

Tawakoli T, Azarhoushang B, Rabiey M (2008) Ultrasonic assisted dry grinding of 42CrMo4. Int J Adv Manuf Tech 42:883–891

Abdullah A, Sotoodezadeh M, Abedini R, Fartashvand V (2013) Experimental study on ultrasonic use in dry creep-feed up-grinding of aluminum 7075 and steel X210Cr12. Int J Precis Eng Man 14:191–198

Tawakoli T, Westkämper E, Azarhoushang B (2009) Effects of vibration-assisted grinding on wear behavior of vitrified bond Al2O3 wheel. Adv Mat Res 76–78:21–26

Spur G, Holl SE (1996) Ultrasonic assisted grinding of ceramics. J Mater Process Techn 62:287–293

Astashev VK, Babitsky VI (1998) Ultrasonic cutting as a non-linear (vibro-impact) process. Ultrasonics 36:89–96

Qin N, Pei ZJ, Treadwell C, Guo DM (2009) Physics-based predictive cutting force model in ultrasonic-vibration-assisted grinding for titanium drilling. J Manuf Sci E-T ASME 131:111–119

Overcash JL, Cuttino JF (2009) In-process modeling of dynamic tool-tip temperatures of a tunable vibration turning device operating at ultrasonic frequencies. Precis Eng 33:505–515

Jaeger JC, Carslaw HS (1947) Conduction of heat in solids. Oxford University Press, London

Guo C, Malkin S (1996) Inverse heat transfer analysis of grinding, part 1: methods. J Eng Ind 118:137–142

Guo C, Malkin S (1996) Inverse heat transfer analysis of grinding, part 2: applications. J Eng Ind 118:143–149

Xu X (2001) Experimental study on temperatures and energy partition at the diamond-granite interface in grinding. Tribol Int 34:419–426

Ro PI, Loh B-G (2001) Feasibility of using ultrasonic flexural waves as a cooling mechanism. IEEE T Ind Electron 48:143–150

Saito Y, Nishiwaki N, Ito Y (1979) An investigation of local heat transfer during grinding process—effects of porosity on grinding wheel. J Eng Ind 101:97–103

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahaddalkar, P.M., Miller, M.H. Force and thermal effects in vibration-assisted grinding. Int J Adv Manuf Technol 71, 1117–1122 (2014). https://doi.org/10.1007/s00170-013-5537-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5537-1