Abstract

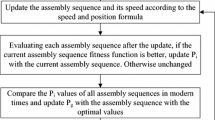

The demands on assembly accuracy require accurate operations both in machining and assembly in order to achieve the high performance of products. Although advanced machining technologies can be used to satisfy most of the demands on precision assembly, the corresponding manufacturing cost will also be increased. Selective assembly provides an effective way for producing high-precision assembly from relatively low-precision components. The accuracy of selective assembly is mainly based on the number of groups and the range of the group (allocated equally on the design tolerance). However, there are often surplus parts in some groups due to the imbalance of mating parts, especially in the cases of undesired dimensional distributions, which makes the methods developed and reported in the literature often not suitable for practice. In this work, a particle swarm optimization (PSO) algorithm is proposed by applying batch selective assembly method to a complex assembly with three mating components (as in ball bearing: an inner race, ball and outer race), to minimize the surplus parts and thereby maximizing the assembly efficiency. Due to the continuous nature of particle swarm optimization algorithm, standard PSO equations cannot be used to generate discrete combination of mating parts. An effective encoding scheme is developed to make the combination of mating parts feasible. The evolution performance of the PSO algorithm with different control parameter values is also analysed.

Similar content being viewed by others

References

Fang XD, Zhang Y (1995) A new algorithm for minimizing the surplus parts in selective assembly. Comput Ind Eng 28:341–350

Chan KC, Linn RJ (1998) A grou** method for selective assembly of parts of dissimilar distributions. Qual Eng 11(2):221–234

Kannan SM, Jayabalan V (2001) A new grou** method for minimizing the surplus parts in selective assembly. Qual Eng 14(1):67–75

Kern DC (2003) Forecasting manufacturing variation using historical process capability data: application for random assembly and serial processing. Dissertation, Massachusetts Institute of Technology, pp 137–188

Chen M-S (1996) Optimising tolerance allocation for mechanical components correlated by selective assembly. Int J Adv Manuf Technol 12:349–355

Mease D, Sudjianto A, Nair VN (2004) Selective assembly in manufacturing: statistical issues and optimal binning strategies. Technometrics 46(2):165–175

Kannan SM, Asha A, Jayabalan V (2005) A new method in selective assembly to minimize clearance variation for a radial assembly using genetic algorithm. Qual Eng 17:595–607

Stoll HW (1999) Product design methods and practices. CRC Press, Boca Raton, USA

Wang Y (2008) Semantic tolerance modelling with generalized intervals. J Mech Des. doi:10.1115/1.2936900, Volume 130, Issue 8, 7 pages

Fu**o Y (1987) Matching problem when lot size is large. Reports of Statistical Application Research 34:1–10

Shan HS, Satyawadi A (1989) Computer-aided component selection for precision assembling. 10th international conference on production research, University of Nottingham, UK, pp. 734–739

Coullard CR, Gamble AB, Jones PC (1998) Matching problems in selective assembly operations. Ann Oper Res 76:95–107

Akachai Jantayavichit (2000) Efficient algorithms for tolerance improvement through selective assembly. Ph.D. thesis, University of Wisconsin-Madison, pp 128–160

Kannan SM, Sivasubramanian R, Jayabalan V (2008) Particle swarm optimization for minimizing assembly variation in selective assembly. Int J Adv Manuf Technol 42:793–803

Parrish A (1973) Mechanical engineer's reference book. Butterworths, London

Osma A (2009) A statistical approach to comparing whell hub forging processes. Proc Int Mech Eng Part D, Journal of Automobile Engineering 223:1559–1576

Lind DA, Marchal WG, Wathen SA (2005) Statistical techniques in business and economics, 12th edn. McGraw-Hill Irwin, New York

Kennedy J, Eberhart RC (1995) Particle swarm optimization. Proceedings of the IEEE International Conference on Neural Networks, Perth, Australia, pp 1942–1948

Shi YH, Eberhart RC (1998) A modified particle swarm optimizer. IEEE International Conference on Evolutionary Computation, Anchorage, Alaska, 4–9 May 1998

Shi YH, Eberhart RC (1998) Parameter selection in particle swarm optimization. 1998 Annual Conference on Evolutionary Programming, San Diego

Eberhart RC, Shi YH (1998) Comparison between genetic algorithm and particle swarm optimization. 1998 Annual Conference on Evolutionary Programming, San Diego

Chen YM, Lin CT (2007) A particle swarm optimization approach to optimize component placement in printed circuit board assembly. Int J Adv Manuf Technol 35:610–620

Lv H, Lu C (2010) An assembly sequence planning approach with a discrete particle swarm optimization algorithm. Int J Adv Manuf Technol 50:761–770

Liu B, Wang L, ** YH (2007) An effective hybrid particle swarm optimization for no-wait flow shop scheduling. Int J Adv Manuf Technol 31:1001–1011

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Raj, M.V., Sankar, S.S. & Ponnambalam, S.G. Particle swarm optimization algorithm to maximize assembly efficiency. Int J Adv Manuf Technol 59, 719–736 (2012). https://doi.org/10.1007/s00170-011-3512-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3512-2