Abstract

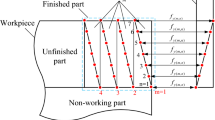

A method for predicting simultaneous dynamic stability limit of thin-walled workpiece high-speed milling process is described. The proposed approach takes into account the variations of dynamic characteristics of workpiece with the tool position. A dedicated thin-walled workpiece representative of a typical industrial application is designed and modeled by finite element method. The curvilinear equation of modal characteristics changing with tool position is regressed. A specific dynamic stability lobe diagram is then elaborated by scanning the dynamic properties of workpiece along the machined direction throughout the machining process. The results show that, during thin-walled workpiece milling process, material removing plays an important part on the change of dynamic characteristics of system, and the stability limit curves are dynamic curves with time–variable. In practical machining, some suggestion is interpreted in order to avoid the vibrations and increase the chatter free material removal rate and surface finish. Then investigations are compared and verified by high-speed milling experiments with thin-walled workpiece.

Similar content being viewed by others

References

Wiercigroch M, Budak E (2001) Sources of nonlinearities, chatter generation and suppression in metal cutting. Phil Trans R Soc Lond A 359:663–693

Balachandran B (2001) Nonlinear dynamics of milling processes. Phil Trans R Soc Lond A 359:793–819

Tobias SA (1977) Machine tool vibration. China Machine Press, Bei**g

Smith S, Tlusty J (1990) Update on high-speed milling dynamics. Trans ASME J Eng Ind 112:142–149

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. Ann CIRP 44:357–362

Davies MA, Pratt JR, Dutterer B, Burns TJ (2002) Stability prediction for low radial immersion milling. Trans ASME J Manuf Sci Eng 124:217–225

Faassen RPH, van de Wouw N, Nijimeijer H, Oosterling JAJ (2007) An improved tool path model including periodic delay for chatter prediction in milling. J Comput Nonlinear Dynam 2:167–179

Long XH, Balachandran B, Mann BP (2007) Dynamics of milling processes with variable time delays. Nonlinear Dynam 47:49–63

Seguy S, Insperger T, Arnaud L, Dessein G, Peigne G (2010) On the stability of high-speed milling with spindle speed variation. Int J Adv Manuf Technol 48:883–895

Park SS, Qin YM (2007) Robust regenerative chatter stability in machine tools. Int J Adv Manuf Technol 33:389–402

Smith S, Snyder J (2001) A cutting performance based template for spindle dynamics. Ann CIRP 50:259–262

Schmitz TL, Davies MA, Medicus K, Snyder J (2001) Improving high-speed machining material removal rates by rapid dynamic analysis. Ann CIRP 50:263–268

Tian JF, Hutton SG (2001) Chatter instability in milling systems with flexible rotating spindles—a new theoretical approach. Trans ASME J Manuf Sci Eng 123:1–9

Movahhedy MR, Mosaddegh P (2006) Prediction of chatter in high speed milling including gyroscopic effects. Int J Mach Tools Manuf 46:996–1001

Chen CK, Tsao YM (2006) A stability analysis of turning a tailstock supported flexible work-piece. Int J Mach Tools Manuf 46:18–25

Heisel U, Feinauer A (1999) Dynamic influence on workpiece quality in high speed milling. Ann CIRP 48:321–324

Tang AJ, Liu ZQ (2009) Three-dimensional stability lobe and maximum material removal rate in end milling of thin-walled plate. Int J Adv Manuf Technol 43:33–39

Davies MA, Balachandran B (2000) Impact dynamics in milling of thin-walled structures. Nonlinear Dynam 22:375–392

Bravo U, Altuzarra O, López de Lacalle LN, Sánchez JA, Campa FJ (2005) Stability limits of milling considering the flexibility of the workpiece and the machine. Int J Mach Tools Manuf 45:1669–1680

Lan JVL, Marty A, Debongnie JF (2007) Providing stability maps for milling operations. Int J Mach Tools Manuf 47:1493–1496

Mane I, Gagnol V, Bouzgarrou BC, Ray P (2008) Stability-based spindle speed control during flexible workpiece high-speed milling. Int J Mach Tools Manuf 48:184–194

Thevenot V, Arnaud L, Dessein G, Cazenave-Larroche G (2006) Integration of dynamic behaviour variations in the stability lobes method: 3D lobes construction and application to thin-walled structure milling. Int J Adv Manuf Technol 27:638–644

Insperger T, Mann BP, Stépán G, Bayly PV (2003) Stability of up-milling and down-milling, part 1; alternative analytical methods. Int J Mach Tools Manuf 43:25–34

Insperger T, Stépán G (2002) Semi-discretization method for delayed systems. Int J Numer Methods Eng 55:503–518

Hartung F, Insperger T, Stepan G, Turi J (2006) Approximate stability charts for milling processes using semi-discretization. Appl Math Comput 174:51–73

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Q., Ai, X. & Tang, W. Prediction of simultaneous dynamic stability limit of time–variable parameters system in thin-walled workpiece high-speed milling processes. Int J Adv Manuf Technol 55, 883–889 (2011). https://doi.org/10.1007/s00170-010-3139-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3139-8