Abstract

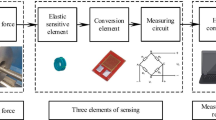

To realize on-line monitoring interelectrode gap, six-axis force sensor was embedded into main spindle of machine tool to measure force signals on cathode exerted by electrolyte. The force signals, three forces, and three moments in X, Y, Z directions, respectively, are considered as research parameters. On one hand, the forces exerted on the tool cathode by electrode are measured with six-axis force sensor as electrolyte flow system is activated and electrode is deactivated. On the other hand, the forces are tested when electrolyte flow system and electrode are both activated. Then, the relation between six force components and interelectrode gap are analyzed. Machining experiments using three types of tool, e.g., plane tool, slant tool, and blade tool, have been carried out to deduct experiential equations between six force components and gap according to least squares method. Furthermore, the experimental data with blade tool are put into experiential equation with slant tool to examine validity of measuring gap in ECM. The relation of parameters in equations is analyzed and a conclusion is drawn: in the range of 15% error, machining experiential equation with slant tool can be used to on-line measure the interelectrode gap in ECM.

Similar content being viewed by others

References

Yu CY (1993) Aviation manufacture process manual: special machining fascicule. Aviation Industry Publishing House, Bei**g

Wang JY, Xu JW (2001) ECM principle and application. National Defence Industry Publishing House, Bei**g

Zhu D, Rajurkar KP (1999) Modeling and verification of interelectrode gap in electrochemical machining with passivating electrolyte. J Manuf Sci Eng 10:589–596

Rajurkar KP, Zhu D, McGeough JA, De Silva A (1999) New developments in electro-chemical machining. CIRP Annals-ManufacturingTechnology 48(2):567–579

Rajurkar KP, Wei B, Kozak J (1995) Modelling and monitoring interelectrode gap in pulse electrochemical machining. CIRP Annals-Manufacturing Technology 44(1):177–180

Zhu D, Rajurkar KP, Wei B (1997) Modeling and monitoring and control systems. J Manuf Sci Eng Trans ASME 119(4):770–775

Wei B, Rajurkar KP, Talpallikar S (1997) Identification of interelectrode gap sizes in pulse electrochemical machining. J Electrochem Soc 144(11):3913–3919

Zhu D (2000) The latest advances and the principal issues in ECM. J Electromachining Mould 1:11–16

Zaytsev A, Agafonov I, Gimaev N, Moukhoutdinov R (2004) Precise pulse electrochemical machining by bipolar current: Aspects of effective technological application. J Mater Process Technol 149(1–3):419–425

Clifton D, Mount AR, Alder GM, Jardine D (2002) Ultrasonic measurement of the inter-electrode gap in electrochemical machining. Inter J Mach Tools Manuf 42:1259–1267

Lu YH, Zhao DB, Zhu D (2004) Mechanical property analysis of inter-electrode gap in electrochemical machining based on six force components. Chin J Mech Eng 15(23):2142–2145

Lu YH, Zhao DB, Lv X, Li J (2005) Design and analysis for elastic body of Stewart six-axis force/torque sensor. J Nan**g Univ Aeron Astron 37(3):78–82

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y., Liu, K. & Zhao, D. Experimental investigation on monitoring interelectrode gap of ECM with six-axis force sensor. Int J Adv Manuf Technol 55, 565–572 (2011). https://doi.org/10.1007/s00170-010-3105-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3105-5