Abstract

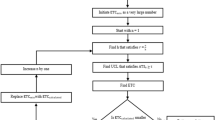

Silicon wafer slicing is a complex manufacturing process, complicating efforts to monitor process stability and quality control effectively. However, silicon wafer slicing involves several synchronously occurring multiple quality characteristics that require close monitoring and control. Therefore, this study applies the Chinese philosophy of yin and yang to illustrate relative management and control wafer slicing quality, and provides decision makers with philosophical thoughts for balancing the simultaneous consideration of various factors. Furthermore, to increase process yield and accurately forecast the next wafer slice quality, grey forecasting is applied to constantly and closely monitor slicing machine drift and quality control.

Similar content being viewed by others

References

Lin CT, Chen CB, Chang CW (2002) Screening synchronously occurred multiple abnormal quality characteristics screening in a silicon wafer slicing process. Asian J Qual 3(1):48–60

ASTM F534 (1995) Annual Book of ASTM Standards

ASTM F657 (1995) Annual Book of ASTM Standards

Lin CT, Chen CB, Chang CW (2003) Focus groups: impact factors of quality and process capability on silicon wafer slicing process. J Technol Manage 8(1):121–133

Laozi, Roberts M (Translator) (2001) Dao De **g: The book of the way. University of California Press, Berkeley, CA

Deng J (1999) Grey system theory and applications. Kao-Li, in Chinese

Deng J (1989) Introduction to grey system theory. J Grey Syst 1(1):1–24

Lin ZC, Lin WS (2001) The application of grey theory to the prediction of measurement points for circularity geometric tolerance. Int J Adv Manuf Technol 17(5):348–360

Hsieh C H, Chou JH, Wu YJ (2002) Optimal predicted fuzzy PI gain scheduling controller of constant turning force systems with fixed metal removal rate. Int J Adv Manuf Technol 19(10):714–721

Lin CT, Yang SY (2003) Forecast of the output value of Taiwan’s opto-electronics industry using the grey forecasting model. Technol Forecasting Social Change 70(2):177–186

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, CT., Chang, CW. & Chen, CB. Relative control philosophy – balance and continual change for forecasting abnormal quality characteristics in a silicon wafer slicing process. Int J Adv Manuf Technol 26, 1109–1114 (2005). https://doi.org/10.1007/s00170-004-2067-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2067-x