Abstract

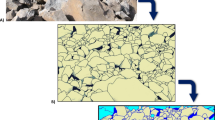

Rock fragmentation as one of the most important blasting results plays an indispensable role in subsequent stages such as secondary breakage, loading, hauling, crushing and grinding, and relevant energy consumption. Since several rock mass properties, blasthole parameters, and powder factor can affect the fragmentation results, development of an accurate model to predict fragment size has long been a complicated subject. In this study, rock mass properties, blasthole parameters, powder factor (q), and fragment size distribution of blasted rock using image analysis technique were determined for several blasting operations in different zones of Sungun open pit copper mine, Rashakan limestone mine, Soufian limestone mine, and Golgohar open pit iron mine. The median fragment size (X50) varied from 10.4 to 32.1 cm, and the predicted X50 by the modified Kuz–Ram models was significantly different from the X50 of the results. Because only a coefficient has been changed from one model to another and the impact of the combination of the parameters on X50 has not yet been well investigated, the impact of individual essential parameters such as blasthole diameter (ϕh), charge per blasthole (Q), rock mass properties, and q on the X50, X80, and uniformity index (n) was originally analyzed to clarify how their combination affects the fragment size of blasted rocks. ϕh and Q had a similar or a parallel effect on the fragmentation results. Two types of relations between X50 with the new combination of Q, q, SANFO, and blastability index (BI) and X50 with the combination of ϕh, q, SANFO, and BI with acceptable correlations were obtained and the correlations also increased when the parameter of joint plane spacing (JPS) was adjusted in the BI system. At the end, a new empirical model was achieved to predict X50 as a function of combination of Q, q, SANFO and adjusted BI with higher correlation (R2 = 0.865), less root mean square error (RMSE = 3.3 cm), and less coefficient of variation (CV = 19.9%) with actual field results.

Similar content being viewed by others

References

Chung SH, Katsabanis PD (2000) Fragmentation prediction using improved engineering formula. Int J Blast Fragment (Fragblast) 4:198–207

Cunningham CVB (1983) The Kuz-Ram model for prediction of fragmentation from blasting. In: Holmberg R, Rustan A (eds) Proceedings of 1st International Symposium on Rock Fragmentation by Blasting, Lulea, Sweden, 22–26 August 1983. Tekniska Universitet, Lulea, pp 439–453

Cunningham CVB (1987) Fragmentation estimations and the Kuz-Ram model-four years on. In: Fourney WL, Dick RD (eds) Proceedings of 2nd International Symposium on Rock Fragmentation by Blasting, Keystone, CO, 23–26 August 1987. Society of Experimental Mechanics, Bethel, pp 475–487

Cunningham CVB (2005) The Kuz-Ram fragmentation model-20 years on. In: Proceedings of 3rd World Conference on Explosives and Blasting, Brighton, UK, 13–16 September 2005, pp 201–210

Curry JA, Ismay MJL, Jameson GJ (2014) Mine operating costs and the potential impacts of energy and grinding. Miner Eng 56:70–80. https://doi.org/10.1016/j.mineng.2013.10.020

Day PR, Webster WK (1981) Controlled blasting to minimize overbreak with big boreholes underground, CIL Inc. CIMM Annual Meeting, Calgary

Deng Y, Yin F, Deng H, Li J, Liu W (2020) Research on crack propagation and rock fragmentation efficiency under spherical tooth dynamic indentation. Arab J Geosci 13:30. https://doi.org/10.1007/s12517-019-4926-7

Dhekne PY, Pradhan M, Jade RK, Mishra R (2017) Boulder prediction in rock blasting using artificial neural network. ARPN J Eng Appl Sci 12(1):47–61

Faramarzi F, Mansouri H, Ebrahimi Farsangi MA (2013) A rock engineering systems based model to predict rock fragmentation by blasting. Int J Rock Mech Min Sci 60:82–94

Gheibie S, Aghababaei H, Hoseinie SH, Pourrahimian Y (2009) Modified Kuz-Ram fragmentation model and its use at the Sungun Copper Mine. Int J Rock Mech Min 46(6):967–973

Grundstrom C, Kanchibotla S, Jankovic A, Thornton DM (2001) Blast fragmentation for maximising the SAG mill throughput at Porgera goldmine. Twenty-Seventh Annual Conference on Explosives and Blasting Te, Orlando, Florida, 28-31 January. The Internat. Soc. of Explosive Engineers, Cleveland, p 2001

Gustafsson R (1973) Swedish blasting technique. Published by SPI, Gothenburg, pp 61–62

Holmberg R, Persson PA (1978) The Swedish approach to contour blasting, Proceedings of the 4th Conference on Explosives and Blasting Technique. pp. 113-127.

Hudaverdi T, Kulatilake Kulatilake PHSW, Kuzu C (2011) Prediction of blast fragmentation using multivariate analysis procedures. Int J Numer Anal Methods Geomech 35:1318–1333

Inanloo Arabi Shad H, Sereshki F, Ataei A, Karamoozian M (2017) Investigation of rock blast fragmentation based on specific explosive energy and in-situ block size. International Journal of Mining and Geo-Engineering 52(1):1–6

ISRM (1978a) Suggested methods for determining hardness and abrasiveness of rocks. In: Brown ET (ed) Rock characterization, testing and monitoring: ISRM suggested methods. Pergamon, Oxford, pp 95–96

ISRM (1978b) Suggested methods for the quantitative description of discontinuities in rock masses. In: Brown ET (ed) Rock characterization, testing and monitoring: ISRM suggested methods. Pergamon, Oxford, pp 346–350

Kabwe E (2019) Velocity of detonation measurement and fragmentation analysis to evaluate blasting efficacy, Journal of Rock Mechanics and Geotechnical Engineering. Vol. 10:523e533

Kanchibotla SS, Valery W, Morrell S (1999) Modelling fines in blast fragmentation and its impact on crushing and grinding. EXPLO ‘99–A conference on rock breaking. The Australasian Institute of Mining and Metallurgy, Kalgoorlie, pp 137–144

Koshelev EA, Kuznetsov VM, Sofronov ST, Chernikov AG (1971) Statistics of the fragments forming with the destruction of solids by explosion. J Appl Mech Tech Phys 12(2):244–256

Kulatilake PHSW, Qiong W, Hudaverd T, Kuzu C (2010) Mean particle size prediction in rock blast fragmentation using neural networks. Eng Geol 114:298–311

Kuznetsov VM (1973) The mean diameter of the fragments formed by blasting rock. Sov Min Sci 9:144–148

Lilly PA (1986) An empirical method of assessing rock mass blastability. In: Davidson JR (ed) Proceedings of Large Open Pit Mine Conference, Newman, WA, October 1986. The Australasian Institute of Mining and Metallurgy, Parkville, pp 89–92

Lilly PA (1992) The use of blastability index in the design of blasts for open pit mines. In: Szwedzicki T, Baird GR, Little TN (eds) Proceedings of Western Australian Conference on Mining Geomechanics, Kalgoorlie, West Australia, 8–9 June 1992. Western Australia School of Mines, Kalgoorlie, pp 421–426

Maerz NH, Palangio TC, Franklin JA (1996) WipFrag image based granulometry system. Proceedings of the FRAGBLAST 5 Workshop on Measurement of Blast Fragmentation, Montreal, Quebec, Canada, 91-99

Mahmood W, Mohammed A (2020) Hydraulic conductivity, grain size distribution (GSD) and cement injectability limits predicted of sandy soils using Vipulanandan models. Geotech Geol Eng 38:2139–2158. https://doi.org/10.1007/s10706-019-01153-z

Michaux S, Djordjevic N (2005) Influence of explosive energy on the strength of the rock fragments and SAG mill throughput. Min Eng 18:439–448

Monjezi M, Rezaei M, Yazdian Varjani A (2009) Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int J Rock Mech Min Sci 46(8):1273–1280. https://doi.org/10.1016/j.ijrmms.2009.05.005

Monjezi M, Bahrami A, Yazdian Varjani A (2010) Simultaneous prediction of fragmentation and flyrock in blasting operation using artificial neural networks. Int J Rock Mech Min Sci 47(3):476–480

Morin MA, Ficarazzo F (2006) Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz-Ram model. Comput Geotech 32:352–369

Nadolski S (2018) Cave-to-mill: mine and mill integration for block cave mines, PhD Thesis, Mining Engineering Department, Faculty of Graduate and Postdoctoral Studies, The University of British Columbia, Vancouver

Nourian A, Moomivand H (2020) Development of a new model to predict uniformity index of fragment size distribution based on the blasthole parameters and blastability index. J Min Sci 56(1):47–58

Olofsson SO (1990) Application explosive technology for construction and mining. Applex, Sweden

Onederra I, Riihioja K (2006) An alternative approach to determine the uniformity index of Rosin-Rammler based fragmentation models. Proceedings of the 8th Int. Symp. on Rock Frag. by Blast. 193-199

Ouchterlony F (2016) The case for the median fragment size as a better fragment size descriptor than the mean. Rock Mech Rock Eng 49:143–164 (2016. https://doi.org/10.1007/s00603-015-0722-1

Ouchterlony F, Nyberg U, Olsson M, Vikström K, Svedensten P, Bergskolan i F (2010) Optimal fragmentering i krosstäkter, fältförsök i Långåsen, Swebrec report 2010: 2. Luleå, Swedish Blasting Research Centre (in Swedish)

Ouchterlony F, Nyberg U, Olsson M, Vikström K, Svedensten P (2015) Effects of specific charge and electronic delay detonators on fragmentation in an aggregate quarry, building KCO design curves. In: Fragblast 11, proceedings of the 11th international symposium on rock fragmentation by blasting. Carlton, AusIMM, pp 727–739

Ouchterlony F, Sanchidrián JA, Moser P (2017) Percentile fragment size predictions for blasted rock and the fragmentation-energy fan. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-016-1094-x

Protodyakonov MM (1962) Mechanical properties and drillability of rocks. Proceedings of the fifth US symposium on rock mechanics. Minneapolis: University of Minnesota. pp. 103-118

Rosin P, Rammler E (1933) The laws governing the fineness of powdered coal. J Inst Fuel 7:29–36

Roy MP, Paswan RK, Sarim M, Kumar S, Jha R, Singh PK (2016) Rock fragmentation by blasting – a review. J Mines Met Fuels 64(9):424–431

Sadegheslam G, Moomivand H (2020) The significant reduction in cost price by changing excavation from blasting to mechanical method based on rock mass properties in Sardar Bucan limestone mine. JMRE 5(1):22–26. https://doi.org/10.30479/JMRE.2019.10495.1252

Sanchidrián JF, Ouchterlony F (2017) A distribution-free description of fragmentation by blasting based on dimensional analysis. Rock Mech Rock Eng 50:781–806. https://doi.org/10.1007/s00603-016-1131-9

Sari M, Lever PJA (2007) Effect of blasted rock particle size on excavation machine loading performance. In: Karpuz C, Hindistan MA, Tercan AE (eds) 20th International Mining Congress and Exhibition of Turkey-IMCET2007, pp 121–126

Sereshki F, Hoseini SM, Ataei M (2016) Blast fragmentation analysis using image processing. Int J Min Geo-Eng 50(2):211–218

Shams S, Monjezi M, Majd VJ, Jahed Armaghani D (2015) Application of fuzzy inference system for prediction of rock fragmentation induced by blasting. Arab J Geosci 8:10819–10832. https://doi.org/10.1007/s12517-015-1952-y

Shi X, Huang D, Zhou J, Zhang S (2013) Fragmentation distribution due to blasting. J Inf Computat Sci 10(11):3511–3518

Silva JD, Amaya JG, Basso F (2017) Development of a predictive model of fragmentation using drilling and blasting data in open pit mining. J South Afr Inst Min Metall 117:1089–1094

Singh SP, Narendrul R (2007) Factors affecting the productivity of loaders in surface mines. Int J Min Reclam Environ. https://doi.org/10.1080/13895260500261574

Split Desktop (2015) Split Engineering LLC Team, Manual of Split Desktop Image Analysis Software, Version 3.1. P.O. Box 41766, Tucson, AZ 85717-1766. www.spliteng.com

Sudhakar J, Adhikari GR, Gupta RN (2006) Comparison of fragmentation measurements by photographic and image analysis techniques. Rock Mech Rock Eng 39(2):159–168

Tosun A, Konak G, Toprak T, Karakus D, Onur AH (2014) Development of the Kuz-Ram model to blasting in a limestone quarry. Arch Min Sci 59(2):477–488

Acknowledgments

The authors would like to thank Mr. D. Taghizadeh, Mining Engineer of Rashakan Limestone Mine; Mr. M. Baghernegad, Managing Director of Sungun Open Pit Copper Mine; Mr. Akbarifar, Mining Engineer of Sungun Copper Mine; Mr. Ahmadzadeh, Mining Engineer of Soufian Limestone Mine; and Mr. A. Hamzehnejadi, Mining Engineer of Golgohar Open Pit Iron mine, for their continuous support during carrying out the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Rights and permissions

About this article

Cite this article

Moomivand, H., Vandyousefi, H. Development of a new empirical fragmentation model using rock mass properties, blasthole parameters, and powder factor. Arab J Geosci 13, 1173 (2020). https://doi.org/10.1007/s12517-020-06110-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-06110-2