Abstract

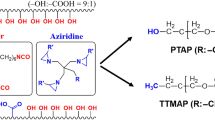

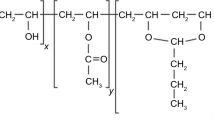

This paper focuses on defining the reaction mechanism involved in the environmental etch of acrylic melamine-based automotive clearcoats via an identification of reaction products. This has been accomplished through a comparative study of products formed on acid treatment of neat crosslinkers, and those formed following laboratory acid treatment and field exposure of acrylic melamine clearcoat systems. Bulk elemental, X-ray photoelectron spectroscopy (XPS), and infrared (IR) analyses of sulfuric acid-treated melamine crosslinkers show that acid hydrolysis results primarily in the formation of melamine sulfate. Melamine sulfate formation was also observed following laboratory and field exposure of acrylic melamine clearcoat systems. These results confirm that the primary mode of melamine crosslink decomposition is through hydrolysis of acetal linkages and subsequent formation of melamine sulfates. However, data show that hydrolysis of pendent amino groups on the triazine ring also occurs.

Similar content being viewed by others

References

Gregorovich, B.V. and Hazan, I.,Prog. Org. Coat., 245, 131–146 (1994).

Rogers, W.R., Garner, D.P., and Cheever, G.D., “Study of the Attack of Acidic Solutions on Melamine-Acrylic Basecoat/Clearcoat Paint Systems,”Journal of Coatings Technology, 70, No. 877, 83 (1998).

Wernståhl, K.M. and Carlsson, B., “Durability Assessment of Automotive Coatings—Design and Evaluation of Accelerated Tests,”Journal of Coatings Technology, 69, No. 865, 69 (1997).

Shultz, U. and Trubiroha, P., ASTM STP 1294, Herling, R.J. (Ed.), American Society for Testing and Materials, Philadelphia, 1996.

Holubka, J.W., Schmitz, P.J., and Xu, L., “Acid Etch Resistance of Automotive Clearcoat. I: Laboratory Test Method Development,”Journal of Coatings Technology, 72, No. 901, 77 (2000).

Schmitz, P.J., Holubka, J.W., and Xu, L., “Acid Etch of Automotive Clearcoats II: Comparision of Degradation Chemistry in Laboratory and Field Testing,”Journal of Coatings Technology, 72, No. 902, 53 (2000).

Edney, E.O., Cheek, S.F., Corse, E.W., Spence, J.W., and Haynie, F.H.,J. Environ. Sci. Health Part A, 24, No. 5, pp. 439–457 (1989).

Edney, E.O., Cheek, S.F., Stiles, D.C., Corse, E.W., and Wheeler, M.L.,Mater. Perform., 27, No. 3, pp. 47–50 (1988).

Smolin, E.M. and Rapoport, L.,The Chemistry of Heterocyclic Compounds, S. Triazines and Derivatives, Interscience Publishers Inc., New York, 1959.

Bauer, D.R., “Chemical Criteria for Durable Automotive Topcoats,”Journal of Coatings Technology, 66, No. 835, 57 (1994).

Wolff, G.T., Rogers, W.R., Collins, D.C., Verma, M.H., and Wong C.A.,J. Air Waste Manage. Assoc., 40, 1638–1648 (1990).

Author information

Authors and Affiliations

Additional information

Ford Research Laboratory, P.O. Box 2053, MD 3083 SRL, Dearborn MI 48121. E-mail: pschmit1@ford.com

Rights and permissions

About this article

Cite this article

Schmitz, P.J., Holubka, J.W. & Xu, LF. Mechanism for environmental etch of acrylic melamine-based automotive clearcoats: Identification of degradation products. Journal of Coatings Technology 72, 39–45 (2000). https://doi.org/10.1007/BF02698018

Issue Date:

DOI: https://doi.org/10.1007/BF02698018