Abstract

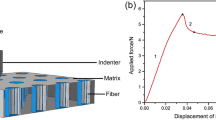

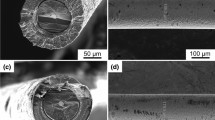

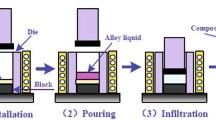

The formation of fiber-matrix interfacial reaction zone and its impact on mechanical properties of Gr/201 Al composite (41 vol pct fiber) was evaluated in the as-received condition and after heat treatment in vacuum at 450°C, 500°C, and 545°C temperatures for one day, and at 545°C for one week. After heat treatment the microstructures of matrix and interface were studied by transmission electron microscopy. This study revealed the presence of interfacial constituents Al4C3, Al4O4C, and TiB2. The mean fiber-matrix reaction zone thickness showed an increase with increasing heat treatment temperature and time. The effects of heat treatment on interfacial shear strength, monotonic and cyclic tension/compression properties were evaluated. The results show that the interfacial shear strength not only depends on chemical reaction but also depends on the thickness of the reaction zone. An increase in reaction zone size reduces mechanical bonding considerably (thermal induced stresses). The growth of reaction zone was very detrimental to monotonic and cyclic tension/tension fatigue behavior. The mechanism of failure in tension/tension fatigue was the initiation of cracks at the interface and their subsequent propagation in the matrix. It was concluded that the reaction zone was the controlling factor in tension/tension fatigue. In contrast, the results showed that compressional fatigue was matrix dependent and was little sensitive to the size of the fiber/matrix interfacial reaction zone.

Similar content being viewed by others

References

R. J. Diefendorf:Proceedings—Critical Issues in Materials Technology Workshop on Transverse Strength in Carbon Fiberi aluminum Composites, Naval Surface Weapon Center, R.N. Lee, ed., April 1984, pp. 2–43 to 2–82.

M. F. Amateau:J. Composite Materials, Oct. 1976, vol. 10, pp. 279–96.

G. Blankenburgs,The J. of Australian Institute of Metals, Nov. 1969, vol. 14, no. 4, pp. 236–41.

W.C. Harrigan, Jr.,Metall. Trans. A, 1978, vol. 9A, pp. 503–07.

P.W. Jackson:Metals Engineering Quarterly, Aug. 1969, pp. 22–30.

I.H. Khan,Metall. Trans. A 1976, vol. 7A, pp. 1281–89.

R.T. Pepper and R.A. Penty:J. Composite Materials, 1974, vol. 8, pp. 29–37.

K. Motoki and A. Okura:Progress in Science and Engineering of Composites, T. Hayashi, K. Kowata, and S. Umekawa, eds., ICCM-IV, Tokyo, 1982.

L. **angun, Z. Hanlin, and W. Renjie:Proc. of the 5th Int. Conf. on Composite Materials (ICCM-V), W.C. Harrigan, Jr.et al., eds., AIME Publication, 1985, pp. 623–29.

V. Provenzano, R.J. Weimer, and S.C. Sandy:4th Int. Conf. on Mechanical Behavior of Materials, Stockholm, Sweden, 1983.

M.F. Amateau and W.D. Hanna:Proc. of the 1975 Int. Conf. on Composite Materials (ICCM), Scala, E. Anderson, I. Toth, and B. R. Noton, eds., AIME, 1976, vol. 1.

K.D. Shimmin and I.J. Toth: inFailure Modes in Composites I, I.J. Toth, ed., The Metallurgical Society-American Institute of Mining, Metallurgical, and Petroleum Engineers, 1973, p. 357.

J.L. Christian: ASTM STP 569, American Soceity for Testing and Materials, 1975, pp. 280–92.

A.A. Baker, D.M. Braddick, and P.W. Jackson:J. Mater. Sci., 1972, vol. 7, pp. 747–62.

D.S. Mahulikar, Y.H. Park, and H.L. Marcus: ASTM STP 791, 1983, pp. II-579 to II-597.

P.C. Paris and G.C. Sih: ASTM STP 381, American Society for Testing and Materials, 1965, pp. 133–96.

G.C. Sih and P.E. Chen:J. of Composite Materials, 1973, vol. 7, pp. 230–44.

G.C. Sih, P.E. Chen, S.L. Huang, and E.J. McQuillan:J. of Composite Materials, 1975, vol. 9, pp. 167–86.

H. T. Corten: inFracture, Col. 7, Academic Press, 1972, pp. 675–769.

T. Tirosh,Engineering Fracture Mechanics, 1980, vol. 13, pp. 119–127.

H.J. Kanish, Jr.: ASTM STP 593, American Society for Testing and Materials, 1975, pp. 99–116.

T.Y. Kosolapora:Carbides, translated by N.B. Vangham, Plenum Press, New York, NY, 1971.

A.P. Majidi, J.M. Yang, R.B. Pipes, and T.W. Chou:Proc. of the 5th Int. Conf. on Composite Materials (ICCM-V) W.C. Harrigan, Jret al., eds., AIME Publications, 1985, pp. 1247–65.

H.T. Hahn, K.L. Jernia, and W. Chiou:Proc. of Int. Symp. on Composite Materials and Structures, E.T.T. Loo and C.T. Sun, eds., Technomic Publishing Co., June 10–13, 1986, pp. 68–74.

M.F. Ashby and D. H. Jones:Engineering Materials, Pergamon Press, 1980.

Engineering Property Data on Selected Ceramics, Carbides, Metals and Ceramics Information Center, Battelle Columbus Laboratories, 505 King Ave., Columbus, OH 43201, Aug. 1979, vol. 2, pp. 5.2.2-1 to 5.2.2.-6

K.J.A. Brooks:World Directory and Handbook of Hardmetals, Engineer's Digest and International Carbide Data, 1982, pp. 49–50.

R.D. Cook and W.C. Young:Advanced Mechanics of Materials, Macmillan Publishing Co., New York, NY, 1985.

A. Kelly and W.R. Tyson: inHigh Strength Materials, V.F. Zackay, ed., John Wiley and Sons, 1964, pp. 578–602.

G.J. Dvorak and J.Q. Tarn: ASTM STP 569, 1975, pp. 145–68.

J.L. Christian: ASTM STP 569, 1975, pp. 280–294, 522.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nayeb-Hashemi, H., Seyyedi, J. Study of the interface and its effect on mechanical properties of continuous graphite fiber-reinforced 201 aluminum. Metall Trans A 20, 727–739 (1989). https://doi.org/10.1007/BF02667590

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02667590