Abstract

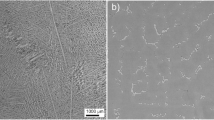

The effect of homogenization temperature on microfissuring in the heat-affected zones of electronwelded cast INCONEL 718 has been studied. The material was homogenized at various temperatures in the range of 1037 ° to 1163 ° and air-cooled. The homogenized material was then electron-beam welded by the bead-on-plate welding technique. The microstructures and microfissuring in the heat-affected zone (HAZ) were evaluated by analytical scanning electron microscopy (SEM). The grain boundary segregation of various elements was evaluated by secondary ion mass spectroscopy (SIMS). It was observed that the total crack length (TCL) of microfissures first decreases with homogenization temperature and then increases, with a minimum occurring in the specimen heat treated at 1163 °. This trend coincides with the variation in segregation of B at grain boundaries with homogenization temperature and has been explained by equilibrium and nonequilibrium segregation of B to grain boundaries during the homogenization heat treatment. No other element was observed to segregate at the grain boundaries. The variation in volume fraction of phases like δ-Ni3Nb, MC carbide, and Laves phases does not follow the same trend as that observed for TCL and B segregation at the grain boundaries. Therefore, microfissuring in HAZ of welded cast INCONEL 718 is attributed to the segregation of B at the grain boundaries.

Similar content being viewed by others

References

H.L. Eiselstein: inAdvances in the Technology of Stainless Steels and Related Alloys, ASTM STP 369, Philadelphia, PA, 1965, pp. 62–77.

R.G. Thompson, J.J. Cassimus, D.E. Mayo, and J.R. Dobbs:Welding J., 1985, vol. 66, pp. 91s-96s.

R.G. Carlson and J.F. Radavich: inSuperalloy 718—Metallurgy and Applications, E.A. Loria, ed., Pittsburgh, PA, 1989, pp. 79–95.

R.G. Thompson and S. Genculu:Welding J., 1983, vol. 62, pp. 337s- 345s.

P.J. Valdez and J.B. Steinman: inEffects of Minor Elements on the Weldability of High-Nickel Alloys, Welding Research Council, New York, NY, 1969, pp. 93–120.

R.G. Thompson, J.R. Dobbs, and D.E. Mayo:Welding J., 1986, vol. 65, pp. 299s-304s.

R.G. Thompson, D.E. Mayo, and B. Radhakrishnan:Metall. Trans. A, 1991, vol. 22A, pp. 557–67.

T.J. Kelly:Welding J., 1989, vol. 70, pp. 44s-51s.

R.G. Thompson, B. Radhakrishnam, and D.E. Mayo:J. Phys. Colloq., 1988, 49 (10), pp. 471–79.

X. Huang: Ph.D. Thesis, University of Manitoba, Winnipeg, MB, Canada, 1994.

M. Guttmann and D. Mclean: inInterfacial Segregation, W.C. Johnson and J.M. Balkely, eds., Metals Park, OH, 1979, pp. 261–347.

J.H. Westbrook and K.T. Aust:Acta Metall., 1963, vol. 1, pp. 1151- 63.

T.R. Anthony:Acta Metall, 1969, vol. 17, pp. 603–09.

Xu Tingdong, Song Shenhua, Yuan Shexi, and Yu Zongsen:J. Mater. Sci., 1990, vol. 25, pp. 1739–44.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Huang, X., Chaturvedi, M.C. & Richards, N.L. Effect of homogenization heat treatment on the microstructure and heat- affected zone microfissuring in welded cast alloy 718. Metall Mater Trans A 27, 785–790 (1996). https://doi.org/10.1007/BF02648966

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02648966