Abstract

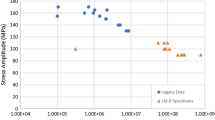

Fatigue crack growth rates were measured at room temperature in dry air for three 7075-T6 aluminum alloys with different inclusion content. Volume fractions of inclusions were determined for each alloy by the point count method with two different automated systems. Plots of the fatigue crack growth rate (da/dN) vs the stress-intensity-factor range (ΔK) show a well defined change of slope at the transition between plane strain and plane stress fracture. This transition is associated with a marked increase in the amount of fracture by void growth around inclusions. The volume fraction and mean spacing of voids within the cyclic plastic zone have been determined as a function of ΔK by quantitative fractography. Fracture by voids is important when the mean spacing of such voids is approximately equal to the width of the cyclic plastic zone in the plane of the crack. It is concluded that the inclusion content increases the fatigue-crack growth rates only within the plane stress range, that is for values of the stress-intensity-factor range ΔK \s> 20 kpsi√in.

Similar content being viewed by others

References

P. J. E. Forsyth:The Physical Basis of Metal Fatigue, p. 143, American Elsevier Publishing Company, New York, 1969.

A. J. McEvily: “Effect of Constituent Particles on the Notch-Sensitivity and Fatigue Crack Propagation Characteristics of Aluminum-Zinc-Mangesium Alloys”, NASA, TD D328, April, 1962.

R. M. Pelloux:Trans. ASM, 1964, vol. 57, pp. 511–18.

W. F. Brown and J. E. Srawley:Amer. Soc. Test. Mater., Spec. Tech. Publ, no. 410, 1966, p. 11.

E. E. Underwood:Quantitative Stereology, pp. 5, 14, 18, 160, 173, 183, Addison-Wesley, Reading, Massachusetts, 1970.

G. T. Hahn, R. G. Hoagland, and A. R. Rosenfield:Local Yielding Attending Fatigue Crack Growth, AF 33615-70-C-1630, Battelle Memorial Institute, Columbus, Ohio, unpublished research, 1971.

J. E. Milliard:Proceedings of the Second International Congress for Stereology, p. 138, Springer-Verlag New York Inc., Chicago, April, 1967.

A. S. Tetelman and A. J. McEvily:Fracture of Structural Materials, p. 138, John Wiley and Sons, New York, 1967.

A. J. McEvily and T. L. Johnston:Int. Conf. on Fracture, Sendai, Japan, 1965, vol. 2, p. 515.

R. J. Selines and R. M. Pelloux: “Effect of Cyclic Stress Wave Forms on Cor-rosion-Fatigue Crack Propagation in Al-Zn-Mg Alloys”, Air Force Materials Laboratory, AFML-TR-72-21, February, 1972.

National Aero-and Astronautical Research Institute,Reports and Transactions, XXXI, Amsterdam, 1965, pp. 63–73.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

El-Soudani, S.M., Pelloux, R.M. Influence of inclusion content on fatigue crack. Metall Trans 4, 519–531 (1973). https://doi.org/10.1007/BF02648705

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02648705