Abstract

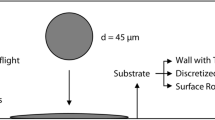

Finite-element methods have been applied for the spreading process of a ceramic liquid droplet impacting on a flat cold surface under plasma spraying conditions. The goals of the present investigation are to predict the geometrical form of the splat as a function of process parameters, such as initial temperature and velocity, and to follow the thermal field develo** in the droplet up to solidification. A nonlinear finite-element procedure has been extended to model the complex physical phenomena involved in the impact process. The dynamic motion of the viscous melt in the drops as constrained by elastic surface tensions and in interaction with the develo** contact with the target has been coupled to transient thermal phenomena to account for the solidification of the material. A model is used to study the impact of spherical particles of liquid ceramic of given temperature and velocity on a flat, cool rigid surface. The deformation of the splat geometry as well as the evolution of the thermal field within the splat are followed up to the final state and require adaptive discretization techniques. The proposed model can be used to correlate flattening degrees with the initial process parameters.

Similar content being viewed by others

References

J.H. Zaat, A Quarter Century of Plasma Spraying,Ann. Rev. Mater. Sci., Vol 13,1983, p 9–42

A. Vardelle, M. Vardelle, and P. Fauchais, Les Transfers de Quantité de Mouvement et de Chaleur Plasma Particules Solides dans un Plasma d’Arc en Estinction,Rev. Int. Hautes Temp. Refract., Vol 23, 1986, p 69–85 (in French)

P. Fauchais, A. Grimaud, A. Vardelle, and M. Vardelle, La Projection par Plasma: Une Revue,Ann. Phys., Vol 14, 1989, p 261–310 (in French)

D.S. Rickerby, G. Eckold, K.T. Scott, and I.M. Buckley-Golder, The Interrelationship between Internal Stress, Processing Parameters and Mi- crostructure of Physically Vapor Deposited and Thermally Sprayed Coatings,Thin Solid Films, Vol 154,1987, p 125–141

R. McPherson, A Review of Microstructure and Properties of Plasma Sprayed Ceramic Coatings,Surf. Coat. Technot., Vol 39–40, 1989, p 173–181

J. Mishin, M. Vardelle, J. Lesinski, and P. Fauchais, Two Colour Pyrometer for the Statistical Measurement of Pariticulate Surface Tem- perature under Thermal Plasma Conditions,J. Phys. E, Vol E20,1987, p 620

C. Moreau, P. Cielo, and M. Lamontagne, Flattening and Solidification of Thermal Sprayed Particles,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 761-766

S. Fantassi, M. Vardelle, P. Fauchais, and C. Moreau, Investigation of the Splat Formation versus Different Particulate Temperatures and Velocities prior to Impact,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 755-760

A.M. Worthington,A Study of Splashes, MacMillan, 1963

G. Trapaga, E.F. Matthys, J.J. Valencia, and J. Szekely, Fluid Flow, Heat Transfer, and Solidification of Molten Metal Droplets Im**ing on Substrates: Comparison of Numerical and Experimental Results,Metall. Trans. B, Vol 23B, 1992, p 701–718

O. Knotek and R. Elsing, Monte Carlo Simulation of the Lamellar Structure of Thermally Sprayed Coatings,Surf. Coat. Technol,Vol 32, 1987, p 261–271

S. Cirolini, J.H. Harding, and G. Jacucci, Computer Simulation of Plasma-Sprayed Coatings: I. Coating Deposition Model,Surf. Coat. Technol., Vol 48,1991, p 137–145

J. Madejski, Solidification of Droplets on a Cold Surface,J. Heat Mass Transfer, Vol 19,1976, p 1009–1013

G. Trapaga and J. Szekely, Mathematical Modeling of the Isothermal Im**ement of Liquid Droplets in Spraying Processes,Metall. Trans. B, Vol 22B, 1991, p 901–914

T. Yoshida, T. Okada, H. Hideki, and H. Kumaoka, Integrated Fabrication Process for Solid Oxide Fuel Cells using Novel Plasma Spraying,Plasma Sources Sci. Technol, Vol 1,1992, p 195–201

S. Fantassi, M. Vardelle, A. Vardelle, and P. Fauchais, Influence of the Velocity of Plasma Sprayed Particles on the Splat Formation,Thermal Spray Coatings: Research, Design and Applications, C.C. Berndt, Ed., ASM International, 1993, p 1-6

J.M. Houben, Future Developments in Thermal Spraying,Thermal Spray Coatings: New Materials, Processes and Applications, F.N. Longo, Ed., ASM International, 1985, p 1-19

J.M. Houben, “Relation of the Adhesion of Plasma Sprayed Coatings to the Process Parameters Size, Velocity and Heat Content of the Spray Particles,” Ph.D. thesis, Technische Universiteit, Eindhoven, The Netherlands, 1988

M. Bertagnolli, M. Marchese, G. Jacucci, I.St. Doltsinis, and S. Noelt- ing, Finite Element Thermomechanical Simulation of Droplets Impacting on a Rigid Substrate,Materials and Design Technology 1994, Vol 62, T.J. Kozik, Ed., American Society of Mechanical Engineers, 1994, p 199-210

J. Argyris, I.St. Doltsinis, H. Fischer, and H. Wüstenberg, \(T\alpha \pi \mathop \alpha \limits^\prime \nu \tau \alpha \rho \varepsilon \tilde \iota \) Computer Meth. Appl. Mech. Eng., Vol 51, 1985, p 289–362

I.St. Doltsinis, J. Luginsland, and S. Nölting, Some Developments in the Numerical Simulation of Metal Forming Processes,Eng. Comput., Vol 4,1987, p 266–280

I.St. Doltsinis, Aspects of Modelling and Computation in the Analysis of Metal Forming,Eng. Comput., Vol 7,1990, p 2–20

I.St. Doltsinis, Coupled Field Problems—Solution Techniques for Sequential and Parallel Processing,Solving Large Scale Problems in Mechanics, M. Papadrakakis, Ed., John Wiley & Sons, 1993

I.St. Doltsinis and S. Nölting, Generation and Decomposition of Finite Element Models for Parallel Computations,Comput. Sys. Eng., Vol 2, 1992, p 427–449

I.St. Doltsinis, M. Eggers, S. Nölting, and G. Nötzel, “Finite Element Modelling of Ceramic Thermal Barrier Coatings to Extend the Operating Range of Heat Engine Components,” 1st Internal Work Report, ICA-Stuttgart, 1992

M. Vardelle, A. Vardelle, P. Fauchais, and C. Moreau, Pyrometer System for Monitoring the Particle Impact on a Substrate during a Plasma Spray Process,Meas. Sci. TechnoL, Vol 5,1994, p 205–212

J.H. Harding, private communication, AEA Technology, Didcot, U.K., 1993

J.L. Fink, M.G. Chasanov, and L. Leibowitz, “Transport Properties of Uranium Dioxide,” ANL-CEN-RSD-80-4, Argonne National Laboratory Report, 1981

R. Westhoff, G. Trapaga, and J. Szekely, Plasma-Particle Interactions in Plasma Spraying Systems,Metall. Trans. B, Vol 23B, 1992, p 683–693

H. Wüstemberg, “FEPS 3.3 Finite Element Programming System: User’s Guide,” ICA Report No. 21, Stuttgart, 1986; “FEPS 3.3: Elements Library,” ICA Report No. 22, Stuttgart, 1986

“Modeling and Characterization of the Manufacturing Process of Ceramic Thermal Barrier Coatings,” BRITE/EURAM Project No. BREU-0418, Second periodical report, CEC, Brussels, 1992

“Modeling and Characterization of the Manufacturing Process of Ceramic Thermal Barrier Coatings,” BRITE/EURAM Project No. BREU-0418, Third periodical report, CEC, Brussels, 1993

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bertagnolli, M., Marchese, M. & Jacucci, G. Modeling of particles impacting on a rigid substrate under plasma spraying conditions. JTST 4, 41–49 (1995). https://doi.org/10.1007/BF02648527

Issue Date:

DOI: https://doi.org/10.1007/BF02648527