Abstract

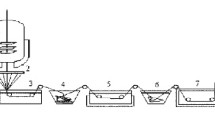

A novel fibrillated particulate microstructure has been fabricated in ultra high molecular weight polyethylene (UHMWPE) that produces a negative Poisson's ratio (auxetic) material. The processing route involves compaction, sintering and extrusion of a UHMWPE fine powder. The first, compaction stage is examined in this paper in detail in order to ascertain the compaction conditions required to produce, as an end-product, an auxetic polymer and to assess the importance of this stage in the processing route. It was found that while part of the function of the compaction stage was to impart structural integrity to the processed polymers, the conditions for optimizing the production of auxetic UHMWPE were not identical to those for optimum structural integrity of the compact. Both sets of conditions were examined, with compaction pressure and temperature being the most important of the variables examined.

Similar content being viewed by others

References

K. L. Alderson and K. E. Evans, Polymer 33 (1992) 4435.

K. E. Evans and B. D. Caddock, J. Phys. D: Appl Phys. 22 (1989) 1883.

B. D. Caddock and K. E. Evans, ibid. 22 (1989) 1877.

K. E. Evans and K. L. Ainsworth, International Patent Publication no. WO91/01210 (1991).

K. E. Evans and K. L. Alderson, J. Mater. Sci. Lett. 11 (1992) 1721.

Hoechst UK Limited, Hoechst House, Salisbury Road, Middlesex TW4 6JH.

K. L. Alderson, A. P. Kettle, P. J. Neale, A. P. Pickles and K. E. Evans, J. Mater. Sci. 30 (1995).

P. J. Neale, A. P. Pickles, K. L. Alderson and K. E. Evans, ibid. 30 (1995).

R. J. Crawford and D. W. Paul, ibid. 17 (1982) 2267.

R. J. Crawford, Polym. Eng. Sci. 22 (1982) 302.

R. W. Truss, K. S. Han, J. F. Wallace and P. H. Geil, ibid. 20 (1980) 747.

Hoechst Plastics, Hostalen GUR (PE-UHMW) datasheets, 6230 Frankfurt an Main 80.

BS 2782: Part 3: Method 341A.

H. S. Loveless, in “Testing of Polymers”, vol. 2, edited by J. V. Schmitz (Interscience Publishers, New York, 1966) p. 321.

P. J. Neale, K. L. Alderson, A. P. Pickles and K. E. Evans, J. Mater. Sci. Lett 12 (1993) 1532.

K. Umeya and R. Hara, Polym. Eng. Sci. 18 (1978) 366.

K. S. Han, J. F. Wallace, R. W. Truss and P. H. Geil, J. Macromol. Sci. Phys. B19 (1981) 313.

K. L. Alderson and K. E. Evans, J. Mater. Sci. 28 (1993) 4092.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pickles, A.P., Webber, R.S., Alderson, K.L. et al. The effect of the processing parameters on the fabrication of auxetic polyethylene. JOURNAL OF MATERIALS SCIENCE 30, 4059–4068 (1995). https://doi.org/10.1007/BF00360709

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00360709