Abstract

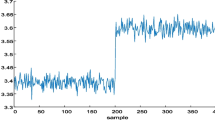

In the grinding process, information about the process state may be derived from many measurement signals. As a result of these signals preprocessing, it is possible to obtain a high number of features of which only a part is related to the monitored process. This paper deals with the feature selection problem and modeling of relationships of selected features with grinding process states and grinding results. Firstly, time–frequency signal processing techniques are analyzed. Using the Hilbert-Huang transform, force, vibration, and acoustic emission signals are decomposed into separate intrinsic mode functions, and then the statistical features are extracted from these functions. Next, principal component analysis is used to select the most relevant features and to remove redundant data. Finally, decision trees are applied to additionally decrease the number of features and to model the grinding process. Using the proposed approach, it is possible to automate the feature selection process and to effectively diagnose the process state and predict final part quality parameters.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tönshoff, H.K., Friemuth, T., Becker, J.C.: Process monitoring in grinding. Ann. CIRP. 51(2), 551–571 (2002)

Teti, R., Jemielniak, K., O’Donnell, G., Dornfeld, D.: Advanced monitoring of machining operations. Ann. CIRP 59(2), 717–739 (2010)

Lajmert, P., Leżański, P.: Monitoring of the cylindrical plunge grinding process. Arch. Mech. Technol. Autom. 33(3), 3–15 (2013)

Kruszyński, B.W., Lajmert, P.: An intelligent system for online optimization of the cylindrical traverse grinding operation. Proc. Ins. Mech. Eng. Part B J. Eng. Manuf. 3, 355–363 (2006)

Kacalak W., Lipiński D., Krzyżyński T.: On the hybrid system of quality supervising in the automated grinding process. In: Proceedings of the 2nd International Conference—Modern Trends in Manufacturing, Wroclaw, pp. 167–174. (2003)

Wang, Z., Willet, P., Deaguiar, P.R., Webster, J.: Neural network detection of grinding burn from acoustic emission. Int. J. Mach. Tools Manuf. 41, 283–309 (2001)

Bi, J., He, P., He, X., Wang, H.: Research for on-line diagnostic system for intelligent roll grinding. In: IEEE Control and Decision Conference, pp. 5248–5252. (2008)

Jolliffe, I.T.: Principal Component Analysis. Springer, New York (2002)

Lajmert, P., Kruszyński, B., Wrąbel, D., Sikora, M.: A stand for multifaceted examination of the cylindrical OD grinding process (in Polish). Mechanic. 8–9, 273–282 (2013)

Lewandowski D.: Pressure measurement of loads (in Polish). In: Drives and Hydraulic Control, Wroclaw, pp. 144–150. (2002)

Chen, X., Limchimchol, T.: Monitoring grinding wheel redress-life using support vector machines. Int. J. Autom. Comput. 1, 56–62 (2006)

Webster, J., Marinescu, I.: Acoustic emission for process control and monitoring of surface integrity during grinding. Ann. CIRP 43(1), 299–304 (1994)

Hundt, W., Leuenberger, D., Rehsteiner, F., Gygax, P.: An approach to monitoring of the grinding process using acoustic emission (AE) technique. Ann. CIRP 43(1), 295–298 (1994)

Liao, T.W., Ting, C., Qu, J., Blau, P.J.: A wavelet-based methodology for grinding wheel condition monitoring. Int. J. Mach. Tools Manuf 47, 580–592 (2007)

Inasaki, I., Karpuszewski, B., Lee, H.-S.: Grinding chatter—origin and suppression. Ann. CIRP 50(2), 515–534 (2001)

Huang N.E., et al.: The empirical mode decomposition and the Hilbert spectrum for non-linear and non-stationary time series analysis. In: Proceedings of the Royal Society of London Series A, pp. 903–995. (1998)

Liao, T.W.: Feature extraction and selection from acoustic emission signals with an application in grinding wheel condition monitoring. Eng. Appl. Artif. Intell. 23(1), 74–84 (2010)

Quinlan R.J.: Learning with continuous classes, In: Proceedings of the 5th Australian Joint Conference On Artificial Intelligence (World Scientific), pp. 343–348. (1992)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Lajmert, P., Sikora, M., Kruszynski, B., Ostrowski, D. (2018). Application of Principal Component Analysis and Decision Trees in Diagnostics of Cylindrical Plunge Grinding Process. In: Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M. (eds) Advances in Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-68619-6_68

Download citation

DOI: https://doi.org/10.1007/978-3-319-68619-6_68

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68618-9

Online ISBN: 978-3-319-68619-6

eBook Packages: EngineeringEngineering (R0)