Abstract

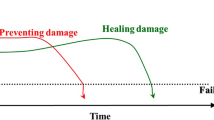

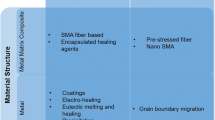

Self-healing technologies in metals have a great potential to improve structures reliability and sustainability in particular in the construction sector. However, limited technologies are available compared to other self-healing material groups and they struggle to find industrial applications. The main limitation for self-healing strategies in metals is the low mobility of atoms at room temperature and often the need for an external driving force to promote mass transfer. This chapter provides a review of all currently developed self-healing concepts in metallic systems classified by their scale and healing process category as: macroscopic systems (including liquid-based systems, shape memory alloys and electro-healing) and solid-state healing of nano and microscale damage. A summary of all strategies is provided and a comprehensive analysis of their advantages and challenges is introduced. Finally, further perspectives of self-healing strategies are discussed and critical points interrupting further development of the existing self-healing materials are highlighted.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Raabe D, Tasan CC, Olivetti EA (2019) Strategies for improving the sustainability of structural metals. Nature 575(7781):64–74

van der Zwaag S, Brinkman E (2015) Self healing materials: pioneering research in the Netherlands. IOS Press.

White SR, Sottos NR et al (2001) Autonomic healing of polymer composites. Nature 409(6822):794–797

Bailey BM, Leterrier Y et al (2015) Electrically conductive self-healing polymer composite coatings. Prog Org Coat 85:189–198

Hautakangas S, Schut H et al (2008) Self-healing of deformation damage in underaged Al–Cu–Mg alloys. Scripta Mater 58(9):719–722

Grabowski B, Tasan C (2016) Self-healing metals. In Self-healing materials, pp 387–407

Sharma S, Nandan G et al (2019) Recent advances in self-healing materials. Mater Today Proc 18:4729–4737

Nosonovsky M, Rohatgi PK (2011) Development of metallic and metal matrix composite self-healing materials. In Biomimetics in materials science, pp 87–122

Srivastava V, Gupta M (2018) Approach to self healing in metal matrix composites: a review. Mater Today Pro 5(9, Part 3):19703–19713

van Dijk N, van der Zwaag S (2018) Self-healing phenomena in metals. Adv Mater Interfaces 5(17)

Song M, Du K et al (2014) In situ electron microscopy investigation of void healing in an Al–Mg–Er alloy at a low temperature. Acta Mater 69:236–245

Zhang S, van Dijk NH, van der Zwaag S (2020) A review of self-healing metals: fundamentals, design principles and performance. Acta Metallurgica Sinica (English Letters) 33(9):1167–1179

Hager MD, Greil P et al (2010) Self-healing materials. Adv Mater 22(47):5424–5430

Fisher CR, Henderson HB et al (2018) Repairing large cracks and reversing fatigue damage in structural metals. Appl Mater Today 13:64–68

Martínez Lucci J, Amano RS, Rohatgi PK (2016) Heat transfer and fluid flow analysis of self-healing in metallic materials. Heat Mass Transfer 53(3):825–848

Martinez Lucci J, Amano RS et al (2008) Experiment and computational analysis of self-healing in an aluminum alloy. In ASME 2008 international mechanical engineering congress and exposition

Kilicli V, Yan X et al (2018) Recent advancements in self-healing metallic materials and self-healing metal matrix composites. Jom 70(6):846–854

Leser P (2014) Mitigation of crack damage in metallic materials. National Aeronautics and Space Administration, Langley Research Center

Nosonovsky M, Rohatgi PK (2011) Biomimetics in materials science: self-healing, self-lubricating, and self-cleaning materials. Springer, New York

Kim J, Kim HJ et al (2018) Thermally-triggered dual in-situ self-healing metallic materials. Sci Rep 8(1):2120–2120

Siroky G, Kraker E et al (2019) Numerical study on local effects of composition and geometry in self-healing solders. In 2019 20th international conference on thermal, mechanical and multi-physics simulation and experiments in microelectronics and microsystems (EuroSimE)

Basaran C, Yan C-Y (1998) A Thermodynamic framework for damage mechanics of solder joints. J Electron Packag 120(4):379–384

Liu P, Yao P, Liu J (2008) Effect of SiC nanoparticle additions on microstructure and microhardness of Sn-Ag-Cu solder alloy. J Electron Mater 37(6):874–879

Siroky G, Kraker E et al (2021) Effect of solder joint size and composition on liquid-assisted healing. Microelectron Reliab 119:114066

Siroky G, Melinc D et al (2020) Healing solders: a numerical investigation of damage-healing experiments. In 2020 21st International conference on thermal, mechanical and multi-physics simulation and experiments in microelectronics and microsystems (EuroSimE)

Manuel MV, Olson G (2007) Biomimetic self-healing metals. In 1st International conference on self-healing materials

Poormir MA, Khalili SMR, Eslami-Farsani R (2018) Optimal design of a bio-inspired self-healing metal matrix composite reinforced with NiTi shape memory alloy strip. J Intell Mater Syst Struct

Poormir MA, Khalili SMR, Eslami-Farsani R (2018) Investigation of the self-healing behavior of Sn-Bi metal matrix composite reinforced with NiTi shape memory alloy strips under flexural loading. Jom 70(6):806–810

Ferguson JB, Schultz BF, Rohatgi PK (2015) Zinc alloy ZA-8/shape memory alloy self-healing metal matrix composite. Mater Sci Eng, A 620:85–88

Wright MC, Manuel M, Wallace T (2013) Fatigue resistance of liquid-assisted self-repairing aluminum alloys reinforced with shape memory alloys shape memory alloy self-healing (SMASH) technology for aeronautical applications. National Aeronautics and Space Administration

Zhu P, Cui Z et al (2016) Characterization and modeling of three-dimensional self-healing shape memory alloy-reinforced metal-matrix composites. Mech Mater 103:1–10

Manuel MV, Fisher CR, Wright MC (2020) Self-repairing metal alloy matrix composites, methods of manufacture and use thereof and articles comprising the same. University of Florida Research Foundation Inc., United States of America

Rohatgi PK (2014) Al-shape memory alloy self-healing metal matrix composite. Mater Sci Eng, A 619:73–76

Salowitz N, Correa A et al (2018) Mechanics of nickel–titanium shape memory alloys undergoing partially constrained recovery for self-healing materials. J Intell Mater Syst Struct

Suri S, Correa A et al (2016) Initial integration of ultrasonic stuctural health monitoring of self-healing materials. In 8th European workshop on structural health monitoring. Bilbao, Spain

Srivastava V, Gupta M (2020) Parametric assessments of self-healing characteristics in AA2014–NiTi-based metallic composites through destructive and nondestructive evaluation. Russ J Nondestr Test 56(12):1064–1082

Zhang S, Kohlbrecher J et al (2013) Defect-induced Au precipitation in Fe–Au and Fe–Au–B–N alloys studied by in situ small-angle neutron scattering. Acta Mater 61(18):7009–7019

Zheng XG, Shi YN, Lu K (2013) Electro-healing cracks in nickel. Mater Sci Eng, A 561:52–59

Hsain Z, Pikul ZH (2019) Low‐energy room‐temperature healing of cellular metals. Adv Funct Mater 29(43)

Song H, Wang ZJ et al (2017) Self-healing of damage inside metals triggered by electropulsing stimuli. Sci Rep 7(1):7097

Kumar A, Paul SK (2020) Healing of fatigue crack in steel with the application of pulsed electric current. Materialia 14

Song H, Wang Z-J (2008) Microcrack healing and local recrystallization in pre-deformed sheet by high density electropulsing. Mater Sci Eng A 490(1–2):1–6

Wang F, Qian D et al (2019) Voids healing and carbide refinement of cold rolled M50 bearing steel by electropulsing treatment. Sci Rep 9(1):11315

Yang CL, Yang HJ et al (2018) Recovery of tensile properties of twinning-induced plasticity steel via electropulsing induced void healing. Scripta Mater 147:88–92

Tang Y, Hosoi A et al (2013) Effect of high-density electric current on the microstructure and fatigue crack initiation of stainless steel. Mater Trans 54(11):2085–2092

Zhou Y, Guo J et al (2004) Crack healing in a steel by using electropulsing technique. Mater Lett 58(11):1732–1736

Yu T, Deng D et al (2016) Crack healing in SUS304 stainless steel by electropulsing treatment. J Clean Prod 113:989–994

Ren X, Wang Z et al (2020) The plastic flow model in the healing process of internal microcracks in pre-deformed TC4 sheet by pulse current. Mater Des 188

Xu W, Yang C et al (2018) Microcrack healing in non-ferrous metal tubes through eddy current pulse treatment. Sci Rep 8(1):6016

Baumans XDA, Lombardo J et al (2017) Healing effect of controlled anti-electromigration on conventional and high-Tc superconducting nanowires. Small 13(26)

Putz B, Glushko O, Cordill MJ (2016) Electromigration in gold films on flexible polyimide substrates as a self-healing mechanism. Mater Res Lett 4(1):43–47

Tao J, Liew BK et al (1998) Electromigration under time-varying current stress. Microelectron Reliab 38(32):295–308

Danzi S, Schnabel V et al (2019) Rapid on-chip healing of metal thin films. Adv Mater Technol 4(3)

Balogh Z, Schmitz G (2014) Diffusion in metals and alloys. In: Laughlin DE, Hono K (eds) Physical metallurgy, 5th edn. Elsevier, Oxford, pp 387–559

Gale W, Totemeier T (1976) Diffusion in metals. In Smithells CJ (ed) Metals reference book, 5th edn.Butterworth-Heinemann, pp 860–939

Neumann G, Tuijn C (2008) Diffusion in Group VII Metals. In Neumann G, Tuijn C (Ed) Pergamon materials series. Pergamon, p 258

Neumann G, Tuijn C (2008) Self-diffusion and impurity diffusion in Group III metals. In Neumann G, Tuijn C (Ed) Pergamon materials series. Pergamon, pp 121–148

Lumley R (2007) Self healing in aluminium alloys. In van der Zwaag S (Ed) Self healing materials: an alternative approach to 20 centuries of materials science. Dordrecht, Springer Netherlands, pp 219–254

Wang H, Huang P, Li Z (2007) Crack and void healing in metals. In van der Zwaag S (Ed) Self healing materials: an alternative approach to 20 centuries of materials science. Springer Netherlands: Dordrecht, pp 255–277

Zhang HL, Sun J (2004) Diffusive healing of intergranular fatigue microcracks in iron during annealing. Mater Sci Eng, A 382(1):171–180

Gao KW, Qiao LJ, Chu WY (2001) In situ TEM observation of crack healing in α-Fe. Scripta Mater 44(7):1055–1059

Wei D, Han J et al (2006) A study on crack healing in 1045 steel. J Mater Process Technol 177(1):233–237

Chen C, Nagao S et al (2016) Self-healing of cracks in Ag joining layer for die-attachment in power devices. Appl Phys Lett 109(9):093503

Kovalenko O, Brandl C et al (2017) Self-Healing and shape memory effects in gold microparticles through the defects-mediated diffusion. Adv Sci (Weinh) 4(8):1700159

Nagai Y, Murayama M et al (2001) Role of vacancy–solute complex in the initial rapid age hardening in an Al–Cu–Mg alloy. Acta Mater 49(5):913–920

Djugum R, Lumley RN et al (2009) Enhanced fatigue resistance in a commercial Al-Cu-Mg alloy through underageing. In Proceedings 2nd international conference on self healing materials

Garrett GG, Knott JF (1975) Crystallographic fatigue crack growth in aluminium alloys. Acta Metall 23(7):841–848

Mahdavi Shahri M, Alderliesten RC et al (2014) Postponing crack nucleation in 2024 aluminium alloy by dynamic precipitation from the supersaturated state. Adv Mater Res 891–892:1577–1584

Mahdavi Shahri M, Ripoll MLR et al (2015) Exploring the option of fatigue life improvement of aluminium AA2024 via dynamic precipitation in the under-aged state. In van der Zwaag S, Brinkman E (eds) Self healing materials: pioneering research in the Netherlands. IOS Press.

Zhang Q, Zhu Y et al (2020) Training high-strength aluminum alloys to withstand fatigue. Nat Commun 11(1):5198

Barter SA, Molent L, Wanhill RJH (2012) Typical fatigue-initiating discontinuities in metallic aircraft structures. Int J Fatigue 41:11–22

Wanhill RJH (2007) Fatigue crack initiation in aerospace aluminium alloys, components and structures. In Proceedings of the first international conference on self healing materials, Noordwijk aan Zee, The Netherlands

Hannard F, Castin S et al (2017) Ductilization of aluminium alloy 6056 by friction stir processing. Acta Mater 130:121–136

Manuel, M.V., Principles of Self-Healing in Metals and Alloys: An Introduction, in Self‐Healing Materials. 2008. p. 251–265.

He SM, van Dijk NH et al (2010) In situ determination of aging precipitation in deformed Fe-Cu and Fe-Cu-B-N alloys by time-resolved small-angle neutron scattering. Phys Rev B 82(17)

He SM, van Dijk NH et al (2010) Thermally activated precipitation at deformation-induced defects in Fe-Cu and Fe-Cu-B-N alloys studied by positron annihilation spectroscopy. Phys Rev B 81(9):094103

Laha K, Kyono J, Shinya N (2007) An advanced creep cavitation resistance Cu-containing 18Cr–12Ni–Nb austenitic stainless steel. Scripta Mater 56(10):915–918

Laha K, Kyono J, Shinya N (2011) Copper, Boron, and Cerium additions in type 347 austenitic steel to improve creep rupture strength. Metall Mater Trans A 43(4):1187–1197

Shinya N, Kyono J, Laha K (2006) Self-healing effect of boron nitride precipitation on creep cavitation in austenitic stainless steel. J Intell Mater Syst Struct 17(12):1127–1133

Zhang S, Langelaan G et al (2014) Preferential Au precipitation at deformation-induced defects in Fe–Au and Fe–Au–B–N alloys. J Alloy Compd 584:425–429

Zhang S, Kwakernaak C et al (2015) Self healing of creep damage by gold precipitation in iron alloys. Adv Eng Mater 17(5):598–603

Zhang S, Kwakernaak C et al (2015) Autonomous repair mechanism of creep damage in Fe-Au and Fe-Au-B-N Alloys. Metall Mater Trans A 46(12):5656–5670

Fang H, Versteylen CD et al (2016) Autonomous filling of creep cavities in Fe-Au alloys studied by synchrotron X-ray nano-tomography. Acta Mater 121:352–364

Versteylen CD, van Dijk NH, Sluiter MHF (2017) First-principles analysis of solute diffusion in dilute bcc Fe-$\mathit{X}$ alloys. Phys Rev B 96(9):094105

Zhang S, Fang H et al (2016) Autonomous filling of grain-boundary cavities during creep loading in Fe-Mo alloys. Metall Mater Trans A 47(10):4831–4844

Fang H, Szymanski N et al (2019) Self healing of creep damage in iron-based alloys by supersaturated tungsten. Acta Mater 166:531–542

Versteylen CD, Sluiter MHF, van Dijk NH (2018) Modelling the formation and self-healing of creep damage in iron-based alloys. J Mater Sci 53(20):14758–14773

Fu Y, Kwakernaak C et al (2021) Surface precipitation of supersaturated solutes in a ternary Fe–Au–W alloy and its binary counterparts. J Mater Sci 56(8):5173–5189

Fu Y, Kwakernaak C et al (2020) Competitive healing of creep-induced damage in a ternary Fe-3Au-4W alloy. Metall Mater Trans A 51(9):4442–4455

Kazanjian SM, Wang N, Starke EA (1997) Creep behavior and microstructural stability of Al-Cu-Mg-Ag and Al-Cu-Li-Mg-Ag alloys. Mater Sci Eng, A 234–236:571–574

Kloc L, Cerri E et al (1996) Significance of continuous precipitation during creep of a powder mettallurgy aluminum alloy. Mater Sci Eng, A 216(1):161–168

Lumley RN, Morton AJ, Polmear IJ (2002) Enhanced creep performance in an Al–Cu–Mg–Ag alloy through underageing. Acta Mater 50(14):3597–3608

Li X, Liu W et al (2016) Radiation resistance of nano-crystalline iron: coupling of the fundamental segregation process and the annihilation of interstitials and vacancies near the grain boundaries. Acta Mater 109:115–127

Bai X-M, Voter AF et al (2010) Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science 327(5973):1631–1634

Borovikov V, Tang X-Z, et al (2013) Coupled motion of grain boundaries in bcc tungsten as a possible radiation-damage healing mechanism under fusion reactor conditions. Nuclear Fusion 53:063001

**ong F, Li M-F et al (2020) Microstructural evolution in amorphous-nanocrystalline ZrCu alloy under neutron irradiation. Acta Mater 182:18–28

Yang L, Li HY et al (2017) Structural responses of metallic glasses under neutron irradiation. Sci Rep 7(1):16739

Zhang S, Cizek J, et al (2020) Self healing of radiation-induced damage in Fe–Au and Fe–Cu alloys: combining positron annihilation spectroscopy with TEM and ab initio calculations. J. Alloys Comp. 817:152765

Zhang S, Yao Z, et al (2020) Irradiation damage and mechanical properties in Fe-Au and Fe-Cu model alloys under helium ion irradiation. Appl Surface Sci 504:144383

Wei D, Han J et al (2004) Simulation of crack healing in BCC Fe. Scripta Mater 51(6):583–587

Zhou G, Gao K et al (2000) Atomistic simulation of microcrack healing in aluminium. Modelling Simul Mater Sci Eng 8:603

Li S, Gao KW et al (2001) Molecular dynamics simulation of microcrack healing in copper. Comput Mater Sci 20(2):143–150

Wang MF, Du GJ, **a DY (2013) Molecular dynamics simulation of microcrack healing in copper nano-plate. Key Eng Mater 531–532:454–457

Karpov EG, Grankin MV et al (2012) Characterization of precipitative self-healing materials by mechanokinetic modeling approach. J Mech Phys Solids 60(2):250–260

Versteylen CD, Szymański NK et al (2018) Finite element modelling of creep cavity filling by solute diffusion. Phil Mag 98(10):864–877

Xu GQ, Demkowicz MJ (2013) Healing of nanocracks by disclinations. Phys Rev Lett 111(14):145501

Meraj M, Pal S (2017) Healing mechanism of nanocrack in nanocrystalline metals during creep process. Appl Phys A 123(2):138

Li J, Fang QH et al (2015) Mechanism of crack healing at room temperature revealed by atomistic simulations. Acta Mater 95:291–301

Michalcová A, Marek I, et al (2018) Phase transformation induced self-healing behavior of Al-Ag alloy. Materials 11(2)

Kloc L, Spigarelli S et al (1997) Creep behavior of an aluminum 2024 alloy produced by powder metallurgy. Acta Mater 45(2):529–540

Sun WW, Fang H et al (2017) Linking surface precipitation in Fe-Au alloys to its self-healing potential during creep loading. Metall Mater Trans A 48(5):2109–2114

Acknowledgements

This chapter writing has been funded by the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (grant agreement n°716678). M.A., J.G and N.N. acknowledge the support of the Fonds de la recherche scientifique—FNRS (FRIA grant), Belgium. F.H. acknowledges the FNRS for his postdoctoral fellowship at UCLouvain.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Arseenko, M., Gheysen, J., Hannard, F., Nothomb, N., Simar, A. (2022). Self-Healing in Metal-Based Systems. In: Kanellopoulos, A., Norambuena-Contreras, J. (eds) Self-Healing Construction Materials. Engineering Materials and Processes. Springer, Cham. https://doi.org/10.1007/978-3-030-86880-2_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-86880-2_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-86879-6

Online ISBN: 978-3-030-86880-2

eBook Packages: EngineeringEngineering (R0)