Abstract

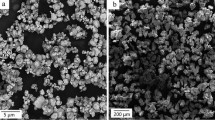

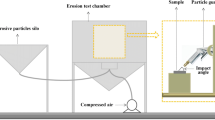

AISI 409 M stainless steel is widely used for manufacturing automobile exhaust systems, automotive mufflers, fuel filters, farm equipment, and ship** containers. The ship** containers and farm equipment during transportation and handling experience wear which reduces their life cycle. To improve the life of AISI 409 M stainless steel, WC-10Co-4Cr powder is cladded on the surface of AISI 409 M steel by gas tungsten arc welding (GTAW) process. Extensive characterization by X-ray diffraction (XRD) and SEM imaging of the cladded AISI 409 M was carried out. The hardness of the cladded AISI 409 M steel specimen and AISI 409 M steel was found to be 42 HRC and 6 HRC, respectively. The wear study of cladded AISI 409 M and AISI 409 M steel specimen was done on pin-on-disk equipment. It was found that the cumulative weight loss of the cladded AISI 409 M steel is 69.73% less than by AISI 409 M steel. The structure property relation shows that wear is proportional to hardness of the cladded AISI 409 M steel.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Sreeraj, P., Kannan, T., & Maji, S. (2013). Prediction and optimization of weld bead geometry in gas metal arc welding process using RSM and fimicon. Journal of Mechanical Engineering, 5(8), 154–165.

Lakshminarayanan, A. K., & Balasubramanian, V. (2012). Sensitization resistance of friction stir welded AISI 409 M grade ferritic stainless steel joints. The International Journal of Advanced Manufacturing Technology, 59, 961–967.

Campos, T., & Lopes de Oliveira, M. C. (2014) Sensitization behavior of type 409 ferritic stainless steel confronting DL-EPR test and practice W of ASTM A763. Journal of Materials Engineering and Performance, 23, 2164–2173.

Buytoz, S., & Ulutan, M. (2002). In situ synthesis of SiC reinforced MMC surface AISI 304 stainless steel by GTAW surface alloying. Surface and Coating Technology, 200(12), 3698–3704.

López, C. E., & Mellor, B. G. (1998). Fracture toughness and crack morphologies in eroded WC–Co–Cr thermally sprayed coatings. Materials Letters, 37, 201–210(1998).

Prakash, G., & Nath, S. K. (2018). Slurry erosion behaviour of micron sized TiC modified WC-10Co-4Cr coating on 13/4 martensitic stainless steel by high velocity oxy fuel process. Journal of Materials Today Proceeding, 5, 17333–17341.

Murthy, J. K. N., Rao, D. S., & Venkataraman, B. (2001) Effect of grinding on the erosion behaviour of a WC–Co–Cr coating deposited by HVOF and detonation gun spray processes. Wear, 249, 592–600.

Yu**, W., & Sheng, H. (2012). Microstructure and cavitation erosion behavior of WC–Co–Cr coating on 1Cr18Ni9Ti stainless steel by HVOF thermal spraying. International Journal of Refractory Metals and Hard Materials, 32, 21–26.

Ravinder, & Jarial, S K. (2015). Parametric Optimization of TIG welding on stainless steel (202) and Mild steel by using Taguchi method. International Journal of Enhanced Research in Science Technology & Engineering. ISSN 2319–7463.

Lailatul, P. H., & Maleque, M. A. (2017). Surface modification of Duplex stainless steel with SiC preplacement using GTAW torch cladding. Advances in Materials and Processing Technologies Conference, 184, 737–742.

Wang, S., Lin, W., & Tsai, Y.Y. (2003). The effects of various ceramic–metal on wear performance of clad layer. Journal of Materials Processing Technology, 140(1–3) 682–687.

Lailatul, H., & Maleque, M. A. (2017). Hardfacing of duplex stainless steel using melting and diffusion processes. Materials Science and Engineering, 184, 012030.

Gochhayat, S. R., & Masanta, M. (2015). Tungsten inert gas (TIG) assisted TiC-Ni coating on AISI 304 stainless steel. ethesis.nitrkl.ac.in.

Ulutan, M., Mustafa yildirim, M., Soner, B., & Celik, O. N. (2010). Microstructure and wear behaviour of GTAW surfaced alloyed AISI 4140 steel. Society of Tribologists and Lubrication Engineers. 10.1050 10402604.519859.

Toro, A., Wojciech, Z., & Misiolek (2003). Correlations between microstructure and surface properties in a high nitrogen martensitic stainless steel. Acta Materialia, 51, 3363–3374.

Dyuthi, S., Mridha, S., & Shaha, S. K. (2010). Surface modification of mild steel using Tungsten inert gas torch surface cladding. American Journal of Applied Sciences, 7, 815–822.

Kumar, V., Gupta, R. D., & Batra, N. K. (2014) Comparison of mechanical properties and effect of sliding velocity on wear properties of Al 6061, Mg 4%, Fly ash and Al 6061, Mg 4%, Graphite 4%, Fly ash Hybrid Metal matrix composite. Procedia Materials Science, 6, 1365–1375.

Pandya, S. N., Nath, S. K., & Chaudhari, G. P. (2009). Friction and wear characteristic of GTAW processed surface modified grey cast iron. Journal of Scientific Research (3), 516–527.

Soni, L., & Masanta, M. (2015). TiC coating on AISI 304 stainless steel by GTAW cladding using pre-placed powder. ethesis.nitrkl.ac.in

Vidarthy, R. S., Dwivedi, D. K., & Vasudevan, M. (2017). Influence of M-GTAW and T-GTAW welding process on microstructure and Mechanical behaviour of 409 ferritic stainless steel. (ASM international) Journal of Material Engineering and Performance, 26, 1391–1403.

Hutchings, I. (1993). Wear by hard particles: Tribology: Friction and wear of materials (pp. 172–182). London: Arnold.

Desouza, V. A., & Nevillle, A. (2003). Corrosion and erosion damage mechanisms during eosion-corosion of WC-Co-Cr cermet coating. Wear, 255, 146–156.

Acknowledgements

The Authors are thankful to the staff of Indian Institute of Technology, Delhi, for carrying out the material characterization. The support of the technical staff of MM (DU), Mullana, Ambala, is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kumar, A., Prakash, G., Batra, N.K. (2021). Enhancement of Adhesive Wear Resistance of AISI 409 M Steel by Deposition of WC-10Co-4Cr Powder Using GTAW Process. In: Sharma, B.P., Rao, G.S., Gupta, S., Gupta, P., Prasad, A. (eds) Advances in Engineering Materials . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-33-6029-7_45

Download citation

DOI: https://doi.org/10.1007/978-981-33-6029-7_45

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6028-0

Online ISBN: 978-981-33-6029-7

eBook Packages: EngineeringEngineering (R0)