Abstract

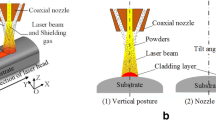

To tackle the laser cladding dimension problems such as complex algorithms and high experimental costs, a prediction model of layer cladding dimension on inclined substrates is proposed, which considers the spot size, energy distribution density and laser energy attenuation. The mathematical model of is carried out based on theory of thermodynamics. The effect of process parameters on the dimensions of the clad layer is also investigated. Finally, laser cladding tests is performed to verify the correctness of the model. The results show that the average error between the experimental and the predicted results for the height and width of the molten layer are 2.46% and 2.4%, respectively, which verified the accuracy of the mathematical model. The simulation model is a guide to the parameter selection and process planning of laser cladding.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Liu, Y., Ye, H.: Prediction of geometric characteristics of laser cladding nickel based coating. J. Mater. Heat Treat. 42(11), 140–146 (2021)

Zhang, B., Hong, L.: Prediction and research of laser fuse cladding appearance and size. China Heavy Equip. 1, 39–40 (2012)

Zhao, H., Yang, X.: Comparative analysis of laser cladding layer morphology prediction. J. Welding 30(1), 51–54+59+115–116 (2009)

Mondal, S., Bandyopadhyay, A.: Application Of artificial neural network for the prediction of laser cladding process characteristics at Taguchi-based optimized condition. Int. J. Adv. Manuf. Technol. 70(9/12), 2151–2158 (2014)

Li, H., Li, T.: Study on the influence of the inclined substrate to the energy distribution of laser cladding. Appl. Laser 37(03), 333–339 (2017)

Tabernero, L.: Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 212(2), 516–522 (2012)

Ya, W., Sanchez, H.: A study on attenuation of a Nd: YAG laser power by CO-axial and off axial nozzle powder stream during cladding. In: 32nd International Congress on Applications of Lasers & Electro-Optics: ICALEO 2013, October 6–10, 2013pp. 447–456. Laser Institute of America, Miami (2013)

Huan, Q., Jyotirmoy, M.: Numerical simulation of heat transfer and fluid flow in coaxial laser cladding process for direct metal deposition. J. Appl. Phys. 100(2), 24903-1-24903-11-0 (2006)

Wang, D.: Study on Laser Cladding Remanufacturing Repair Method of Gear Tooth Surface. Dalian University of Technology, Liaoning (2021)

Wang, Y., Zhong, Y.: Influence of laser remanufacturing process parameters on single-pass forming characteristics of H13 steel powder. Laser Infrared 51(7), 871–876 (2021)

Acknowledgment

The work was supported by the National Natural Science Foundation of China (Grant No. 51975499 and 51975500). These financial supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhou, L., Luo, S., Gao, Z., Huang, H. (2023). Simulation and Experimental Study of Laser Cladding Layer Dimension on Inclined Substrates. In: Wang, Y., Yu, T., Wang, K. (eds) Advanced Manufacturing and Automation XII. IWAMA 2022. Lecture Notes in Electrical Engineering, vol 994. Springer, Singapore. https://doi.org/10.1007/978-981-19-9338-1_43

Download citation

DOI: https://doi.org/10.1007/978-981-19-9338-1_43

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9337-4

Online ISBN: 978-981-19-9338-1

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)