Abstract

Polyhydroxyalkanoates (PHA) are unique polyester of microbial origin with features equivalent to synthetic plastics. Its thermoplastic, biodegradable, biocompatible, and nontoxic characteristic makes it a suitable biopolymer for various sectors of modern sciences and industry, including biomedical and related applications. The physical properties of PHA can be tuned by changing its monomeric units (hydroxyl acids) and/or modifying the flexible R-group present within the monomers. Thus, the PHA polymer can have broad crystallinity, optical, and piezoelectric activities that can be customized. Recent advancements in industrial manufacturing techniques led to the utilization of PHA polymers in sensing applications and develo** microelectronic devices. Sensing devices based on PHA polymer along with other composite materials have been used to detect gases, volatile organic compounds, Urea, H2O2, antibiotics, body fluids, and live microorganisms. In addition, PHA-based devices also found their role as triboelectric nanogenerators, time-temperature indicators, strain sensors, chemosensors, and pressure sensors. In this chapter, these unique applications of PHA in sensing applications will be discussed, along with the recent advancements and associated challenges. The PHA polymers are great alternatives for miniaturized electronic devices with lower ecological impact, and with recent developments in biocomposite fabrication. Soon the PHA-based sensors will find their place in our daily lives.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kumar P, Kim BS. Valorization of polyhydroxyalkanoates production process by co-synthesis of value-added products. Bioresour Technol. 2018;269:544–56.

Kumar P, Ray S, Patel SK, Lee JK, Kalia VC. Bioconversion of crude glycerol to polyhydroxyalkanoate by Bacillus thuringiensis under non-limiting nitrogen conditions. Int J Biol Macromol. 2015;78:9–16.

Kumar P, Patel SK, Lee JK, Kalia VC. Extending the limits of Bacillus for novel biotechnological applications. Biotechnol Adv. 2013;31(8):1543–61.

Singh M, Kumar P, Ray S, Kalia VC. Challenges and opportunities for customizing polyhydroxyalkanoates. Indian J Microbiol. 2015;55(3):235–49.

Stojanović GM, Nikodinović-Runić J, Švenderman S, Kojić T, Radovanović M, Mikov M, Randjelović D. Comprehensive characterization of elastomeric polyhydroxyalkanoate and its sensor applications. Mat Sci Eng C. 2020;115:111091.

Poltronieri P, Kumar P. Polyhydroxyalkanoates (PHAs) in industrial applications. In: Handbook of ecomaterials. Vol. 4. 2017. p. 2843–72.

Kumar P, Kim BS. Paracoccus sp. strain LL1 as a single cell factory for the conversion of waste cooking oil to polyhydroxyalkanoates and carotenoids. Appl Food Biotechnol. 2019;6(1):53–60.

Kumar P, Maharjan A, Jun HB, Kim BS. Bioconversion of lignin and its derivatives into polyhydroxyalkanoates: challenges and opportunities. Biotechnol Appl Biochem. 2019;66(2):153–62.

Kumar P, Ray S, Kalia VC. Production of co-polymers of polyhydroxyalkanoates by regulating the hydrolysis of biowastes. Bioresour Technol. 2016;200:413–9.

Kumar P, Mehariya S, Ray S, Mishra A, Kalia VC. Biodiesel industry waste: a potential source of bioenergy and biopolymers. Indian J Microbiol. 2015;55(1):1–7.

Singh M, Kumar P, Patel SK, Kalia VC. Production of polyhydroxyalkanoate co-polymer by Bacillus thuringiensis. Indian J Microbiol. 2013;53(1):77–83.

Brojanigo S, Alvarado-Morales M, Basaglia M, Casella S, Favaro L, Angelidaki I. Innovative co-production of polyhydroxyalkanoates and methane from broken rice. Sci Total Environ. 2022;825:153931.

Kumar P, Jun HB, Kim BS. Co-production of polyhydroxyalkanoates and carotenoids through bioconversion of glycerol by Paracoccus sp. strain LL1. Int J Biol Macromol. 2018;107:2552–8.

Li T, Elhadi D, Chen GQ. Co-production of microbial polyhydroxyalkanoates with other chemicals. Metab Eng. 2017;43:29–36.

Arumugam A, Sandhya M, Ponnusami V. Biohydrogen and polyhydroxyalkanoate co-production by Enterobacter aerogenes and Rhodobacter sphaeroides from Calophyllum inophyllum oil cake. Bioresour Technol. 2014;164:170–6.

Kumar P, Singh M, Mehariya S, Patel SK, Lee JK, Kalia VC. Ecobiotechnological approach for exploiting the abilities of Bacillus to produce co-polymer of polyhydroxyalkanoate. Indian J Microbiol. 2014;54(2):151–7.

Patel SK, Kumar P, Singh M, Lee JK, Kalia VC. Integrative approach to produce hydrogen and polyhydroxybutyrate from biowaste using defined bacterial cultures. Bioresour Technol. 2015;176:136–41.

Patel SK, Singh M, Kumar P, Purohit HJ, Kalia VC. Exploitation of defined bacterial cultures for production of hydrogen and polyhydroxybutyrate from pea-shells. Biomass Bioenergy. 2012;36:218–25.

dos Santos RR, Corrêa PS, Dantas FML, Teixeira CMLL. Evaluation of the co-production of total carotenoids, C-phycocyanin and polyhydroxyalkanoates by Arthrospira platensis. Bioresour Technol Rep. 2019;7:100226.

Kumar P, Chandrasekhar K, Kumari A, Sathiyamoorthi E, Kim BS. Electro-fermentation in aid of bioenergy and biopolymers. Energies. 2018;11(2):343.

Romero Soto L, Thabet H, Maghembe R, Gameiro D, Van-Thuoc D, Dishisha T, Hatti-Kaul R. Metabolic potential of the moderate halophile Yangia sp. ND199 for co-production of polyhydroxyalkanoates and exopolysaccharides. Microbiologyopen. 2021;10(1):e1160.

Kelwick RJ, Webb AJ, Wang Y, Heliot A, Allan F, Emery AM, et al. AL-PHA beads: bioplastic-based protease biosensors for global health applications. Mater Today. 2021;47:25–37.

Chernozem RV, Romanyuk KN, Grubova I, Chernozem PV, Surmeneva MA, Mukhortova YR, et al. Enhanced piezoresponse and surface electric potential of hybrid biodegradable polyhydroxybutyrate scaffolds functionalized with reduced graphene oxide for tissue engineering. Nano Energy. 2021;89:106473.

Obeso CG, Sousa MP, Song W, Rodriguez-Pérez MA, Bhushan B, Mano JF. Modification of paper using polyhydroxybutyrate to obtain biomimetic superhydrophobic substrates. Colloids Surf A Physicochem Eng Asp. 2013;416:51–5.

Valentini L, Cardinali M, Kenny J. Flexible triboelectric generator and pressure sensor based on poly [(R)-3-hydroxybutyric acid] biopolymer. J Polym Sci B Polym Phys. 2014;52(13):859–63.

Zhu G, Pan C, Guo W, Chen CY, Zhou Y, Yu R, Wang ZL. Triboelectric-generator-driven pulse electrodeposition for micropatterning. Nano Lett. 2012;12(9):4960–5.

Anbukarasu P, Sauvageau D, Elias AL. Time-temperature indicator based on enzymatic degradation of dye-loaded polyhydroxybutyrate. Biotechnol J. 2017;12(9):1700050.

Dan L, Pope MA, Elias AL. Solution-processed conductive biocomposites based on polyhydroxybutyrate and reduced graphene oxide. J Phys Chem C. 2018;122(30):17490–500.

Avossa J, Paolesse R, Di Natale C, Zampetti E, Bertoni G, De Cesare F, et al. Electrospinning of polystyrene/polyhydroxybutyrate nanofibers doped with porphyrin and graphene for chemiresistor gas sensors. Nanomaterials. 2019;9(2):280.

Dan L, Elias AL. Flexible and stretchable temperature sensors fabricated using solution-processable conductive polymer composites. Adv Healthc Mater. 2020;9(16):2000380.

Zheng Q, Zou Y, Zhang Y, Liu Z, Shi B, Wang X, et al. Biodegradable triboelectric nanogenerator as a life-time designed implantable power source. Sci Adv. 2016;2(3):e1501478.

Ma X, Yang R, Li G. Hydrogen peroxide biosensor based on the direct electrochemistry of myoglobin immobilized in poly-3-hydroxybutyrate film. Am J Biochem Biotechnol. 2005;1(1):43–6.

Ma X, Liu X, **ao H, Li G. Direct electrochemistry and electrocatalysis of hemoglobin in poly-3-hydroxybutyrate membrane. Biosens Bioelectron. 2005;20(9):1836–42.

Slaugther G. A gold interdigitated microelectrodes fabricated on polyhydroxybutyrate substrate for the determination of urea using impedimetric measurements. IEEE Sensors J. 2012;12(4):821–6.

Macagnano A, Perri V, Zampetti E, Bearzotti A, De Cesare F. Humidity effects on a novel eco-friendly chemosensor based on electrospun PANi/PHB nanofibres. Sensors Actuators B Chem. 2016;232:16–27.

Moore TL, Aburime SA, Wilson TA, Giannelis EP, Batt CA. Nanofabrication of biodegradable enzyme-based glucose and organophosphorus pesticide biosensors. In: Proceedings of the 2002 National Conference on Environmental Science and Technology, Greensboro, North Carolina, USA, 8–10 Sept 2002. Battelle Press; 2003. p. 225–32.

Phukon P, Radhapyari K, Konwar BK, Khan R. Natural polyhydroxyalkanoate–gold nanocomposite based biosensor for detection of antimalarial drug artemisinin. Mater Sci Eng C. 2014;37:314–20.

Park TJ, Lee SY. A research and application of polyhydroxyalkanoates in biosensor chip. KSBB J. 2007;22(6):371–7.

Hosseini S, Azari P, Jiménez-Moreno MF, Rodriguez-Garcia A, **guan-Murphy B, Madou MJ, Martínez-Chapa SO. Polymethacrylate coated electrospun PHB fibers as a functionalized platform for bio-diagnostics: confirmation analysis on the presence of immobilized IgG antibodies against Dengue virus. Sensors. 2017;17(10):2292.

Chen SY, Harrison M, Ng EK, Sauvageau D, Elias A. Immobilized reporter phage on electrospun polymer fibers for improved capture and detection of Escherichia coli O157: H7. ACS Food Sci Technol. 2021;1(6):1085–94.

Anbukarasu P, Sauvageau D, Elias A. The effects of solvent casting temperature and physical aging on polyhydroxybutyrate-graphene nanoplatelet composites. Polym Compos. 2021;42(3):1451–61.

Sahiner N, Demirci S. The use of graphene oxide-embedded superporous poly(2-hydroxyethylmethacrylate) cryogels for p(aniline) conductive polymer synthesis and their use in sensor applications. Mater Des. 2017;120:47–55.

Avossa J, Zampetti E, De Cesare F, Bearzotti A, Scarascia-Mugnozza G, Vitiello G, et al. Thermally driven selective nanocomposite PS-PHB/MGC nanofibrous conductive sensor for air pollutant detection. Front Chem. 2018;6:432.

Meng X, Tongay S, Kang J, Chen Z, Wu F, Li SS, et al. Stable p-and n-type do** of few-layer graphene/graphite. Carbon. 2013;57:507–14.

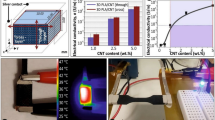

Vallejo-Giraldo C, Pugliese E, Larrañaga A, Fernandez-Yague MA, Britton JJ, Trotier A, et al. Polyhydroxyalkanoate/carbon nanotube nanocomposites: flexible electrically conducting elastomers for neural applications. Nanomedicine. 2016;11(19):2547–63.

Cai Z, **ong P, He S, Zhu C. Improved piezoelectric performances of highly orientated poly (β-hydroxybutyrate) electrospun nanofiber membrane scaffold blended with multiwalled carbon nanotubes. Mater Lett. 2019;240:213–6.

Dan L, Cheng Q, Narain R, Krause B, Pötschke P, Elias A. Three-dimensional printed and biocompatible conductive composites comprised of polyhydroxybutyrate and multiwalled carbon nanotubes. Ind Eng Chem Res. 2021;60(2):885–97.

Acknowledgment

The author wishes to thank Sharda University for providing the necessary facility and moral support to write this chapter. This work was supported by the institutional seed fund funded by Sharda University (SU/SF/2022/04).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ray, S., Kumari, A., Sonkar, M., Kumar, P. (2023). Polyhydroxyalkanoate-Based Sensors and Their Applications. In: Kumar, P., Dash, S.K., Ray, S., Parween, S. (eds) Biomaterials-Based Sensors. Springer, Singapore. https://doi.org/10.1007/978-981-19-8501-0_7

Download citation

DOI: https://doi.org/10.1007/978-981-19-8501-0_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8500-3

Online ISBN: 978-981-19-8501-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)