Abstract

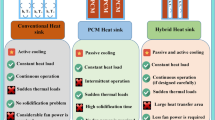

Heat sinks absorb thermal energy from devices which operates at higher temperatures and dissipates to surrounding medium. Overheating of electronic components can reduce the efficiency, reliability and life of energy systems. The focus of most of the researchers is on the improvement of the performance of the heat sinks. The performance of the heat sinks can be enhanced by incorporation of the phase change materials (PCM). In the present work, a novel design of PCM-based finned heat sink is modeled numerically using ANSYS FLUENT. Holes are drilled along the fins and filled with PCM to improve the heat storage capacity of the heat sink. PCM-based heat sinks with high heat dissipating qualities are well suitable for electronic cooling application. In this study, thermal resistance is calculated to analyze the performance of the heat sink. The performance of the PCM-based heat sink is evaluated for various PCM and composite PCMs and compared with the heat sink without PCM.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- A b :

-

Heat sink base area (m2)

- Cp :

-

Specific heat (j/kg K)

- H :

-

Height of the heat sink base

- H e :

-

Enthalpy of suspension (W)

- k :

-

Thermal conductivity (W/m K)

- PCM:

-

Phase change material

- q :

-

Heat flux entering (W/m2)

- R T :

-

Thermal resistance (K/W)

- T :

-

Temperature (K)

- T in :

-

Inlet temperature (K)

- \({\overline{\text{T}}}_{w}\) :

-

Average temperature at heat sink base (K)

- ρ:

-

Density (kg/m3)

- μ:

-

Dynamic viscosity (m2/s)

References

Hung TC, Huang YX, Yan WM (2013) Thermal performance analysis of porous-microchannel heat sinks with different configuration designs. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2013.07.019

Yoon Y, Park SJ, Kim DR, Lee KS (2018) Thermal performance improvement based on the partial heating position of a heat sink. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2018.03.080

Mahmoud S, Tang A, Toh C, et al (2013) Experimental investigation of inserts configurations and PCM type on the thermal performance of PCM based heat sinks. Appl Energy. https://doi.org/10.1016/j.apenergy.2013.04.059

Kandasamy R, Wang XQ, Mujumdar AS (2008) Transient cooling of electronics using phase change material (PCM)-based heat sinks. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2007.06.010

Taghilou M, Khavasi E (2020) Thermal behavior of a PCM filled heat sink: The contrast between ambient heat convection and heat thermal storage. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2020.115273

Kim SH, Heu CS, Kim DR, Kang SW (2020) Numerical modeling and experimental validation of a phase change material-based compact cascade cooling system for enhanced thermal management. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2019.114470

Anzar A, Hafiz PA, Ashiq N, Shaheer M (2016) Heat transfer analysis on PCM based heat sink incorporated with air convection. 7:441–456

Deng X, Wang S, Wang J, Zhang T (2017) Analytical modeling of microchannel heat sinks using microencapsulated phase change material slurry for chip cooling. In: Procedia engineering

Manoj Kumar P, Mylsamy K, Alagar K, Sudhakar K (2020) Investigations on an evacuated tube solar water heater using hybrid-nano based organic phase change material. Int J Green Energy. https://doi.org/10.1080/15435075.2020.1809426

Wang C, Lin T, Li N, Zheng H (2016) Heat transfer enhancement of phase change composite material: copper foam/paraffin. Renew Energy. https://doi.org/10.1016/j.renene.2016.04.039

Yin H, Gao X, Ding J, Zhang Z (2008) Experimental research on heat transfer mechanism of heat sink with composite phase change materials. Energy Convers Manag. https://doi.org/10.1016/j.enconman.2007.10.022

Ho CJ, Gao JY (2009) Preparation and thermophysical properties of nanoparticle-in-paraffin emulsion as phase change material. Int Commun Heat Mass Transf. https://doi.org/10.1016/j.icheatmasstransfer.2009.01.015

Heyhat MM, Mousavi S, Siavashi M (2020) Battery thermal management with thermal energy storage composites of PCM, metal foam, fin and nanoparticle. J Energy Storage. https://doi.org/10.1016/j.est.2020.101235

Cooling performance of micro heat pipe used for mobile. J Eng Perform C 7:331–341 (2018)

Shatikian V, Ziskind G, Letan R (2005) Numerical investigation of a PCM-based heat sink with internal fins. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2004.10.042

Diaconu BM, Varga S, Oliveira AC (2010) Experimental assessment of heat storage properties and heat transfer characteristics of a phase change material slurry for air conditioning applications. Appl Energy. https://doi.org/10.1016/j.apenergy.2009.05.002

Mehrali M, Latibari ST, Mehrali M et al (2013) Shape-stabilized phase change materials with high thermal conductivity based on paraffin/graphene oxide composite. Energy Convers Manag. https://doi.org/10.1016/j.enconman.2012.11.023

Zhang Z, Zhang N, Peng J et al (2012) Preparation and thermal energy storage properties of paraffin/expanded graphite composite phase change material. Appl Energy. https://doi.org/10.1016/j.apenergy.2011.10.014

Lachheb M, Karkri M, Albouchi F et al (2014) Thermophysical properties estimation of paraffin/graphite composite phase change material using an inverse method. Energy Convers Manag. https://doi.org/10.1016/j.enconman.2014.03.021

Dutkowski K, Fiuk JJ (2018) Experimental investigation of the effects of mass fraction and temperature on the viscosity of microencapsulated PCM slurry. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2018.05.158

Arularasan R, Velraj R (2010) Modeling and simulation of a parallel plate heat sink using computational fluid dynamics. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-008-1867-9

Yadav A, Soni S (2017) Simulation of melting process of a phase change material (PCM) using ANSYS (Fluent). Int Res J Eng Technol 2395–56

Hasan MI, Tbena HL (2018) Using of phase change materials to enhance the thermal performance of micro channel heat sink. Eng Sci Technol an Int J 21:517–526. https://doi.org/10.1016/J.JESTCH.2018.03.017

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Naga Ramesh, K., Manoj Sai, M., Vineeth Goud, K., Raghavendra, K., Amruth, S., Karthikeya Sharma, T. (2023). Numerical Analysis of Heat Transfer Enhancement of Heat Sink Using Different Phase Changing Materials for Electronic Cooling Application. In: Mehta, H.B., Rathod, M.K., Abiev, R., Arıcı, M. (eds) Recent Advances in Thermal Sciences and Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-7214-0_25

Download citation

DOI: https://doi.org/10.1007/978-981-19-7214-0_25

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7213-3

Online ISBN: 978-981-19-7214-0

eBook Packages: EngineeringEngineering (R0)