Abstract

Response surface methodology (RSM) was used in conjunction with the miscellaneous design model to identify prediction models for the thermophysical properties of a hybrid cellulose nanocrystal-copper (II) oxide nanolubricant. Minitab 18 statistical analysis software and Response Surface Methodology (RSM) based on Central Composite Design (CCD) were utilised to generate an empirical mathematical model investigating the effect of concentration and temperature. Analysis of variance (ANOVA) is used to validate the significance of the developed empirical mathematical model. Thirteen experiments were conducted to obtain second-order polynomial equations for the desired specific heat capacity, thermal conductivity, and dynamic viscosity, outputs. The predicted values were found to be in reasonable agreement following the investigational finding. In addition, the models could predict more than 80% of the nanolubricant output variations, indicating that the model is accurate. In the optimization plot, the predicted optimal values for dynamic viscosity, thermal conductivity, and specific heat capacity are 2.3631, 0.1463, and 1.6311, respectively. The relevant parameters are 90 °C and 0.1 for temperature and concentration, respectively. The plotted composite is 0.6531. The findings of the percentage of absolute error (POAE) reveal that the model may precisely predict the optimum experimental parameters.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

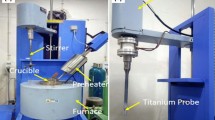

Hisham S, Kadirgama K, Mohammed HA, Kumar A, Ramasamy D, Samykano M, Rahman S (2020) Hybrid nanocellulose-copper (II) oxide as engine oil additives for tribological behavior improvement. Molecules 25(13):2975

Said Z, Rahman S, Assad MEH, Alami AH (2019) Heat transfer enhancement and life cycle analysis of a shell-and-tube heat exchanger using stable CuO/water nanofluid. Sustain Energy Technol Assess 31:306–317

Habibi H, Zoghi M, Chitsaz A, Javaherdeh K, Ayazpour M (2019) Thermo-economic performance comparison of two configurations of combined steam and organic Rankine cycle with steam Rankine cycle driven by Al2O3-therminol VP-1 based PTSC. Sol Energy 180:116–132

Mousavi SB, Heyhat MM (2019) Numerical study of heat transfer enhancement from a heated circular cylinder by using nanofluid and transverse oscillation. J Therm Anal Calorim 135(2):935–945

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H (2019) Recent advances in modeling and simulation of nanofluid flows-part I: fundamentals and theory. Phys Rep 790:1–48

Arjmandi H, Amiri P, Pour MS (2020) Geometric optimization of a double pipe heat exchanger with combined vortex generator and twisted tape: a CFD and response surface methodology (RSM) study. Therm Sci Eng Prog 18:100514

Shankar BR, Rao DN, Rao CS (2012) Experimental investigation on stability of Al2O3-water nanofluid using response surface methodology. Int J Nanosci Nanotechnol 3(2):149–160

Nasirzadehroshenin F, Maddah H, Sakhaeinia H (2020) Experimental and theoretical investigation of thermophysical properties of synthesized hybrid nanofluid developed by modeling approaches. Arab J Sci Eng 45(9):7205–7218

Peng Y, Khaled U, Al-Rashed AA, Meer R, Goodarzi M, Sarafraz M (2020) Potential application of Response Surface Methodology (RSM) for the prediction and optimization of thermal conductivity of aqueous CuO (II) nanofluid: a statistical approach and experimental validation. Physica A 554:124353

Kiran B, Pathak K, Kumar R, Deshmukh D (2016) Statistical optimization using central composite design for biomass and lipid productivity of microalga: a step towards enhanced biodiesel production. Ecol Eng 92:73–81

Kamarulzaman MK, Abdullah A (2020) Multi-objective optimization of diesel engine performances and exhaust emissions characteristics of Hermetia illucens larvae oil-diesel fuel blends using response surface methodology. Energy Sources Part A Recovery Utilization Environ Effects 1–14

Tauler R, Brown SD (2009) Comprehensive chemometrics: chemical and biochemical data analysis. Elsevier Science, Amsterdam

Myers RH, Montgomery DC, Anderson-Cook CM (2011) Response surface methodology: process and product optimization using designed experiments. Wiley, Hoboken

Sakinah M, Hassan M, Kadirgama K, Kadirgama G, Ramasamy D, Amirruddin A, Rahman M, Noor M (2018) Optimization on wear performance of anti wear additive added biolubricant. In: Improved performance of materials. Springer, Berlin, pp 1–9

Ghafari S, Aziz HA, Isa MH, Zinatizadeh AA (2009) Application of response surface methodology (RSM) to optimize coagulation–flocculation treatment of leachate using poly-aluminum chloride (PAC) and alum. J Hazard Mater 163(2–3):650–656

Kumar BR, Saravanan S, Rana D, Nagendran A (2016) Combined effect of injection timing and exhaust gas recirculation (EGR) on performance and emissions of a DI diesel engine fuelled with next-generation advanced biofuel–diesel blends using response surface methodology. Energy Convers Manage 123:470–486

Rostamian H, Lotfollahi MN (2019) A novel statistical approach for prediction of thermal conductivity of CO2 by response surface methodology. Physica A 527:121175

Esfe MH, Firouzi M, Rostamian H, Afrand M (2018) Prediction and optimization of thermophysical properties of stabilized Al2O3/antifreeze nanofluids using response surface methodology. J Mol Liq 261:14–20

Esfe MH, Rostamian H, Shabani-Samghabadi A, Arani AAA (2017) Application of three-level general factorial design approach for thermal conductivity of MgO/water nanofluids. Appl Therm Eng 127:1194–1199

Rostamian H, Lotfollahi MN (2016) New functionality for energy parameter of Redlich-Kwong equation of state for density calculation of pure carbon dioxide and ethane in liquid, vapor and supercritical phases. Periodica Polytech Chem Eng 60(2):93–97

Myers RH, Montgomery DC, Anderson-Cook CM (2016) Response surface methodology: process and product optimization using designed experiments. Wiley, Hoboken

Peng Y, Khaled U, Alrashed AA, Meer R, Goodarzi M, Sarafraz M (2020) Potential application of Response Surface Methodology (RSM) for the prediction and optimization of thermal conductivity of aqueous CuO (II) nanofluid: a statistical approach and experimental validation. Phys A Stat Mech Appl 124353

Hemmat Esfe M, Abbasian Arani AA, Esfandeh S (2018) Improving engine oil lubrication in light-duty vehicles by using of dispersing MWCNT and ZnO nanoparticles in 5W50 as viscosity index improvers (VII). Appl Therm Eng 143:493–506. https://doi.org/10.1016/j.applthermaleng.2018.07.034

Acknowledgements

This work was supported by University Malaysia Pahang [grant number RDU192402]. “Mohd Kamal bin Kamarulzaman” is the recipient of the UMP Post-Doctoral Fellowship in Research.

Credit Authorship Contribution Statement

Sakinah Hisham: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Data Curation, Writing—Original Draft, Visualization. K. Kadirgama, D. Ramasamy, M. Samykano: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Resources, Writing—Review and Editing, Visualization, Supervision. N. W. Awang: Conceptualization, Investigation. Mohd Kamal Kamarulzaman: Conceptualization.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Hisham, S., Kadirgama, K., Ramasamy, D., Samykano, M., Awang, N.W., Kamarulzaman, M.K. (2023). Prediction and Optimization of Thermophysical Properties of Hybrid Cellulose Nanocrystal-Copper (II) Oxide Nanolubricant for Tribology Application. In: Johari, N.H., Wan Hamzah, W.A., Ghazali, M.F., Setiabudi, H.D., Kumarasamy, S. (eds) Proceedings of the 2nd Energy Security and Chemical Engineering Congress. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-4425-3_29

Download citation

DOI: https://doi.org/10.1007/978-981-19-4425-3_29

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4424-6

Online ISBN: 978-981-19-4425-3

eBook Packages: EngineeringEngineering (R0)