Abstract

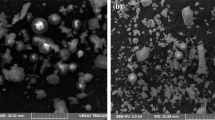

In this research, mechanical and microstructural properties of Fly-ash-based self-compacting geopolymer concrete (SCGC) were investigated for shear strength and impact strength by substituting Fly Ash with Ground Granulated Blast Furnace Slag (GGBS) by 0, 30, 50 and 70% and by using alkali solutions such as sodium hydroxide and sodium silicate in the ratio 1:2.5 for different NaOH solution molarities like 8, 10 and 12 M. An iterative procedure was utilized to arrive at the SCGC design mix by completing workability tests like slump flow in compliance with European Federation of National Associations Representing for Concrete (EFNARC) criteria. After obtaining the requisite flow, the concrete was poured into the moulds and cured for 24 h at 70 °C in the oven, with ambient treatment occurring for the remainder of the test days. A constant binding content of 400 kg/m3 and a fluid to binder ratio of 0.47 by mass have been maintained for all molarities, while the superplasticizer dosage of 3% has remained constant. And by compromising on strength, the extra water content was adjusted to provide the desired flow. With increasing molarity and GGBS, the slump flow was reduced. As GGBS content and molarity increased, engineering properties such as shear and impact strength increased, and this was justified with microstructure analysis. As compared to the other replacement level, the replacement of 70% of the Fly Ash with GGBS at 12 M showed higher structural strength. Hence, fly ash and GGBS in a ratio of 50:50 could be a better CO2-reducing alternative to traditional OPC concrete in connection to cost and sustainability.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

McCaffrey R (2002) Climate change and cement industry. Global Cement and Lime Magazine, environmental special issue, 15–19

Flower DJM, Sanjayan JG (2007) Greenhouse gas emissions due to concrete manufacture. Int J Life Cycle Assess 12:282–288

Mehta PK (2001) Reducing the environmental impact of concrete. Concr Int 23:61–66

Berry M, Cross D, Stephens J (2009) Changing the environment: an alternative “Green” concrete produced without Portland cement. In: World of coal ash (WOCA) conference, Lexington, KY, USA

Ritchie H, Roser M (2020, May 11) Greenhouse gas emissions. Our World in Data. Retrieved 22 June 2021

Roy DM (1999) Alkali-activated cements opportunities and challenges. Cem Concr Res 29:249–254

Topark-Ngarm P, Sata V, Chindaprasirt P (2012) Effects of admixtures on high calcium geopolymer concrete cured at room temperature. In: The 4th KKU international engineering conference

Hardjito D, Rangan BV (2005) Development and properties of low-calcium fly-ash-based geopolymer concrete. Research report GC1. Faculty of Engineering, Curtin University of Technology, Perth, Australia

Wallah SE, Rangan BV (2006) Low-calcium fly-ash-based geopolymer concrete: long-term properties. Research report GC2. Curtin University of Technology, Perth, Australia

Rangan BV (2008) Fly-ash-based geopolymer concrete. Research report GC4, Curtin University of Technology, Perth, Australia

IS: 12089-1987 (1987) Specification of granulated slag for the manufacture of Portland slag cement. Bureau of Indian Standards, New Delhi

Bairagi NK, Modhera CD (2001) Shear strength of fiber-reinforced concrete. ICI J 47–53

Baruah P, Talukdar S (2007) A comparative study of compressive, flexural, tensile and shear strength of concrete with fibres of different origins. Indian Concr J 17–24

IS 456: 2000 (2000) Plain and reinforced concrete-code of practice. Bureau of Indian Standards, India

ACI Committee 544 (1996) State of the art report on fibre reinforced concrete. ACI Committee 544 report 544. 1R-96. American Concrete Institute, Detroit

Song S, Sohn D, Jennings HM, Mason TO (2000) Hydration of alkali-activated ground granulated blast furnace slag. J Mater Sci 35:249–257

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Arun, B.R., Vedamurthy, N.H., Nagaraja, P.S., Mahalingasharma, S.J. (2023). The Effect on Mechanical and Microstructure Properties by Varying GGBS Content and NaOH Solution Concentration in Alkaline Solution of Fly-Ash-Based Self-compacting Geopolymer Concrete. In: Nandagiri, L., Narasimhan, M.C., Marathe, S. (eds) Recent Advances in Civil Engineering. CTCS 2021. Lecture Notes in Civil Engineering, vol 256. Springer, Singapore. https://doi.org/10.1007/978-981-19-1862-9_11

Download citation

DOI: https://doi.org/10.1007/978-981-19-1862-9_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1861-2

Online ISBN: 978-981-19-1862-9

eBook Packages: EngineeringEngineering (R0)