Abstract

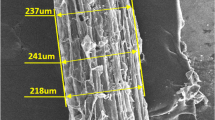

The present study investigates the specific wear rate of camphor soot embedded coir and palmyra fibre reinforced nylon composites (CCFNCs) and (CPFNCs), respectively, with a varying weight percentage of fibre loads (0, 3, 6, 9 wt.%) with an aid of twin screw extruder. The two-body abrasive wear analysis was carried out in accordance with ASTM-G99 using a pin on disc apparatus (dry sliding wear) under ambient conditions and dry contact conditions. Mass was taken as a function of constant sliding velocity of 5 m/s for loads of 10, 15, and 20 N and varying sliding distances of 200, 300, 400 m. using 600 grit SiC abrasive sheets. The influence of abrading distance and varying loads were investigated. Abrasive wear loss and specific wear rate was also studied as a function of abrading distance and normal load. The results revealed that for increased sliding distance and load, weight loss increased in both CCFNCs and CPFNCs. Better results were observed in 6 wt.% composites compared to neat and 9 wt.% fibre loads. Specific wear rate was decreased with an increase in sliding distance and load for both CCFNCs and CPFNCs. Excellent wear characteristics were obtained with a 6 wt.% fibre load compared to 9 wt.% Further, the morphology of worn surfaces of neat nylon, CCFNC and CPFNC observed using a scanning electron microscope (SEM) shows that wear accrued in the form of microploughing, microcracking, debris formation, and brittle fracture in fibres.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Harsha AP, Tewari US (2002) Polym Test 21:697–709

Batchelor AW, Stachowiak GW (1995) J Mater Process Technol 48(1–4):503–515

Suresha B, Seetharamu S, Sampath Kumaran P (2009) Wear 267(9):1405–1414

Unal H, Mimaroglu A, Arda T (2006) Appl Surf Sci 252(23):8139–8146

Sudhir Kumar KP (2015) J Mater Sci Mech Eng 2(6):24–28

Deo C, Acharya SK (2010) Ind J Mater Sci 17:219–223

Reis PNB, Ferreira JAM, Antunes FV, Costa JDM (2007) Compos Part A: App Sci Manuf 38(6):1612–1620

Ba P, Shetty P, B, HV S, Singh Yadav SP (2020) Advances in materials and processing technologies, pp 1–16

Doan TTL, Gao SL, Mäder E (2006) Compos Sci Technol 66(7–8):952–963

Gill NS, Yousif BF (2009) Proceedings of the institution of mechanical engineers. Part J: J Eng Tribol 223(2):183–194

Ayrilmis N, Jarusombuti S, Fueangviva V, Bauchongkol P, RH (2011) Fibers Polym 12(7):919–926

Mohanty AK, Misra M, Hinrichsen G (2000) Macromol Mater Eng 276(1):1–24

Tran LQN, Minh TN, Fuentes CA, Chi TT, Van Vuure AW, Verpoest I (2015) Ind crops Prod 65:437

**ng Y, Zhang G, Ma K, Chen T, Zhao X (2009) Polym-Plast Technol 48(6):633–638

Kumar M, Ando Y (2003) Diamond Relat Mater 12:998–1002

Raghavendra T, Kavan P (2018) Fiber Polym 19(7):1567–1575

Raghavendra T, Panneerselvam K (2020) Fibers Polym 21(11):2569–2578

Raghavendra T, Panneerselvam K (2020) Surf Rev Lett 27(2):1950104

Hager AM, Davies M (1993) Compos Mater Ser 8:107–157

Ye Y, Chen J, Zhou H (2009) Wear 266(7–8):859–864

Cho MH, Bahadur S (2005) Wear 258(5–6):835–845

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Raghavendra, T., Panneerselvam, K. (2023). Abrasive Wear Behaviour of Camphor Soot Filled Coir/Palmyra Fibre Reinforced Nylon Composites. In: Narendranth, S., Mukunda, P.G., Saha, U.K. (eds) Recent Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-1388-4_10

Download citation

DOI: https://doi.org/10.1007/978-981-19-1388-4_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1387-7

Online ISBN: 978-981-19-1388-4

eBook Packages: EngineeringEngineering (R0)