Abstract

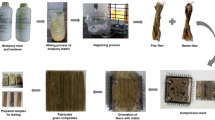

Natural fibre reinforced composites packed with Multi Wall Carbon Nanotubes (MWCNTs) are focused by the researchers due to their great tribo and mechanical properties. To ensure collective mechanical and wear qualities, fibre reinforced polymer composites must be hybridised; thus, this study examines the manufacturing and tribological performance of natural fiber-glass reinforced hybrid composites. Compression moulding was used to combine natural fibres like jute, flax, and banana with glass fibre. Particulate MWCNT were disseminated in epoxy resin through ultrasonic bath sonicator, which was then employed as the matrix face for composites reinforced with natural fibre. The sliding wear behaviour of composites reinforced with glass-natural fiber and filled with MWCNT is evaluated using a pin-on-disc wear testing setup. Using D-optimal design, second-order mathematical models were created to forecast particular rate of wear and friction co-efficient by considering wt% of MWCNT, sliding speed load. The surface morphology of worn-out surfaces was studied by SEM analysis.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Karthikeyan S, Ra**i N, Jawaid M, Winowlin Jappes JT, Thariq MT, Siengchin S, Sukumaran J, (2017), A review on tribological properties of natural fiber based sustainable hybrid composite. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, Dec;231(12):1616–34.

Ramesh M, Palanikumar K, Reddy KH, (2013), Mechanical property evaluation of sisal–jute–glass fiber reinforced polyester composites, Composites Part B: Engineering, May 1;48:1–9.

Rezghi Maleki H, Hamedi M, Kubouchi M, Arao Y,(2019), Experimental investigation on drilling of natural flax fiber-reinforced composites, Materials and Manufacturing Processes, Feb 17;34(3):283–92.

Mohan K, Rajmohan T, (2017), Fabrication and characterization of MWCNT filled hybrid natural fiber composites, Journal of Natural Fibers, Nov 2;14(6):864–74

Rahman M, Das S, Hasan M, (2018), Mechanical properties of chemically treated banana and pineapple leaf fiber reinforced hybrid polypropylene composites, Advances in Materials and Processing Technologies, Oct 2;4(4):527–37.

Palanikumar K, Ramesh M, Hemachandra Reddy K, (2016), Experimental investigation on the mechanical properties of green hybrid sisal and glass fiber reinforced polymer composites, Journal of Natural Fibers, May 3;13(3):321–31.

Jain S, Kumar R, (1994), Processing of bamboo fiber reinforced plastic composites. Material and Manufacturing Process, Aug 1;9(5):813–28.

Mohan K, Rajmohan T, (2018), Effects of MWCNT on mechanical properties of glass-flax fiber reinforced nano composites, Materials Today: Proceedings, Jan 1;5(5):11628–35.

Breuer O, Sundararaj U, (2004), Big returns from small fibers: a review of polymer/carbon nanotube composites, Polymer composites. Dec;25(6):630–45.

Anbusagar NRR, Palanikumar K (2018) Nanoclay Addition and Core Materials Effect on Impact and Damage Tolerance Capability of Glass Fiber Skin Sandwich Laminates. Journal of Silicon 10(3):769–779. https://doi.org/10.1007/s12633-016-9529-2

Ahsan Q, Tee ZW, Rahmah S, Chang SY, Warikh M, (2016), Wear and friction behaviour of magnesium hybrid composites containing silicon carbide and multi-walled carbon nanotubes, Advances in Materials and Processing Technologies, Apr 2;2(2):303–17.

Wang Q-H, Qun-JiXue W-M, Chen J-M (2000) Effect of Nanometer SiC Filler on the Tribological Behavior of PEEK under Distilled Water Lubrication. J Appl Polym Sci 78(3):609–614. https://doi.org/10.1002/1097-4628(20001017)78:33.0.CO;2-D

Hui-juan Zhang, Zhao-Zhu Zhang, Fang Guo, Kun Wang, (2009), Enhanced wear properties of hybrid PTFE/cotton fabric composites filled with functionalised multi-walled carbon nanotubes, Materials Chemistry and Physics, 2009, 116(1),183–190. DOI: https://doi.org/10.1016/j.matchemphys.2009.03.008.

Aly AA, Zeidan ES, Alshennawy AA, El-Masry AA, Wasel WA, (2012), Friction and wear of polymer composites filled by nano-particles: a review. World Journal of Nano Science and Engineering, Mar 28;2(01):32.

Jani S.P. Senthil Kumar, (2018), A Adam Khan. M Uthaya Kumar M. Machinability of hybrid natural fiber composite with and without filler as reinforcement, Materials and Manufacturing Processes, DOI: https://doi.org/10.1080/10426914.2015.1117633.

Zhang XR, Pei XQ, Wang QH, (2007), The effect of fiber oxidation on the friction and wear behaviors of short-cut carbon fiber/polyimide composites, Express Polymer Letters, May 1;1(5):318–25.

Majhi S, Samantarai SP, Acharya SK, (2012), Tribological behavior of modified rice husk filled epoxy composite. International Journal of Scientific & Engineering Research, Jun;3(6):180–4.

Divya GS, Kakhandaki A, Suresha B (2014) Wear behaviour of coir reinforced treated and untreated hybrid composites. International Journal of Innovative Research and Development 3(5):632–639

Rajmohan T, Palanikumar K, (2013), Modeling and analysis of performances in drilling hybrid metal matrix composites using D-optimal design, The International journal of advanced Manufacturing technology, Feb 1;64(9–12):1249–61.

Srinivasan T, Palanikumar K, Rajagopal K, Latha B (2017) Optimisation of Delamination Factor in Drilling GFR-Polypropylene Composites. Mater Manuf Processes. https://doi.org/10.1080/10426914.2016.1151038

Abhemanyu PC, Prassanth E, Navin Kumar T, Vidhyasagar R, Prakash Marimuthu K (2018) Wear Properties of Natural Fiber Composite Materials. AIP Conf Proc. https://doi.org/10.1063/1.5092889

Chang BP, Yong YF, Md Akil H, Md Nasir R, Optimization on Abrasive Wear Performance of Pultruded Kenaf-Reinforced Polymer Composite Using Taguchi Method. KEM https://doi.org/10.4028/www.scientific.net/kem.739.42.

Rajmohan T, Mohan K, Palanikumar K (2015) Synthesis and characterisation of Multi Wall Carbon Nano tube (MWCNT) filled hybrid banana-glass fiber reinforced composites. Appl Mech Mater 766:193–198

Biswal M, Mohanty S, Nayak SK, (2012), Banana fiber-reinforced polypropylene nanocomposites: Effect of fiber treatment on mechanical, thermal, and dynamic-mechanical properties, Journal of Thermoplastic Composite Materials, Sep;25(6):765–90.

Jayaramudu J, Guduri BR, Rajulu AV, (2010), Characterization of new natural cellulosic fabric Grewia tilifolia. Carbohydrate polymers, Mar 17;79(4):847–51.

Bajpai PK, Singh I, Madaan J, (2013), Tribological behavior of natural fiber reinforced PLA composites, Wear, Jan 15;297(1–2):829–40.

Rajmohan T, Palanikumar K, Davim JP, Premnath AA, (2016), Modeling and optimization in tribological parameters of polyether ether ketone matrix composites using D-optimal design Journal of Thermoplastic Composite Materials, Feb;29(2):161–88.

Shang Y, Wu X, Liu Y, Jiang Z, Wang Z, Jiang Z, Zhang H, (2019), Preparation of PEEK/MWCNTs composites with excellent mechanical and tribological properties, High Performance Polymers, Feb;31(1):43–50.

Friedrich K, Karger-Kocsis J, Lu Z (1991) Effect of steel counterface roughness and temperature on the friction and wear of PEEK composites under dry sliding conditions. Wear 148(2):235–247. https://doi.org/10.1016/0043-1648(91)90287-5

Ahmed KS, Khalid SS, Mallinatha V, Kumar SA, (2012) Dry sliding wear behavior of SiC/Al2O3 filled jute/epoxy composites, Materials & Design (1980–2015), Apr 1;36:306–15.

Zhang H-J, Zhang Z-Z, Guo F, Jiang W (2009) Study on the tribological behavior of hybrid PTFE/cotton fabric composites filled with Sb2O3 and melamine cyanurate. Tribol Int. https://doi.org/10.1016/j.triboint.2009.03.002

Dixit S, Verma P (2012) The effect of hybridisation on mechanical behaviour of coir / sisal / jute fibers reinforced polyester composite material. Research Journal of Chemical Sciences 2(6):91–93

Maleque MA, Belal FY, Sapuan SM, (2007), Mechanical properties study of pseudo-stem banana fiber reinforced epoxy composite, The Arabian journal for science and engineering, Oct 1;32(2B):359–64.

Derringer G, Suich R, (1980), Simultaneous optimization of several response variables, Journal of quality technology, Oct 1;12(4):214–9.

Nirmal U, Hashim J, Ahmad MM, (2015), A review on tribological performance of natural fiber polymeric composites, Tribology International, Mar 1;83:77–104.

Kumar D, Rajmohan T, Experimental investigation of wear of multiwalled carbon nanotube particles filled poly-ether-ether ketone matrix composites under dry sliding. Journal of Thermoplastic Composite Materials.https://doi.org/10.1177/0892705718772869.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Rajmohan, T., Mohan, K., Prasath, R., Vijayabhaskar, S. (2022). Tribological Characterization of Hybrid Natural Fiber MWCNT Filled Polymer Composites. In: Palanikumar, K., Thiagarajan, R., Latha, B. (eds) Bio-Fiber Reinforced Composite Materials. Composites Science and Technology . Springer, Singapore. https://doi.org/10.1007/978-981-16-8899-7_19

Download citation

DOI: https://doi.org/10.1007/978-981-16-8899-7_19

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8898-0

Online ISBN: 978-981-16-8899-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)