Abstract

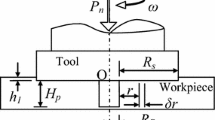

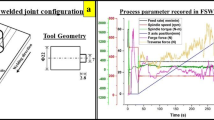

Pipe of AISI-316L austenitic stainless steel was successfully friction stir welded at various speeds (mm/min) and feed rate (RPM). The tool has WRe (Tungsten-Rhenium) shank and convex face with stepped spirals of polycrystalline cubic boron nitride (PCBN) coating over 14.5 mm diameter and 6 mm axial length. The present investigation is done in position control mode of the equipment. The vertical as well as lateral forces were recorded along with the spindle torque. The trends of the forces and torque are presented along with co-relation if any. This would help to understand the influence of the process parameters (welding speed, rotational speed) on the weldment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Brewer LN, Bennett MS, Baker BW, Payzant EA et al (2015) Characterization of residual stress as a function of friction stir welding parameters in oxide dispersion strengthened (ODS) steel MA956. Mater Sci Eng A 647:313–321

Davis JR (1994) ASM specialty handbook, stainless steel. Materials Park, OH

Karjalainen LP, Taulavuori T, Sellman M et al (2008) Some strengthening methods for austenitic stainless steels. Steel Res Int 79:404–412

Mironov S, Sato YS, Kokawa H et al (2011) Structural response of superaustenitic stainless steel to friction stir welding. Acta Mater 59:5472–5481

Kumar SS, Murugan N, Ramachandran KK (2018) Microstructure and mechanical properties of friction stir welded AISI 316L austenitic stainless steel joints. J Mater 254:79–90

Meshram MP, Kodli BK, Dey SR (2014) Friction stir welding of austenitic stainless steel by PCBN tool and its joint analyses. Procedia Mater Sci 6:135–139

Aydin H (2014) Relationship between a bainitic structure and the hardness in the weld zone of the friction-stir welded X80 API-grade pipe-line steel. Mater Technol 48:15–22

Meran C, Kovan V, Alptekin A (2007) Friction stir welding of AISI 304 austenitic stainless steel. Mater Sci Eng Technol 38:829–835

Li H, Yang S, Zhang S et al (2017) Microstructure evolution and mechanical properties of friction stir welding super-austenitic stainless steel S32654. Mater Des 118:207–217

Kumar SS, Murugan N, Ramachandran KK (2016) Influence of tool material on mechanical and microstructural properties of friction stir welded 316L austenitic stainless steel butt joints. Int J Refract Met H 58:196–205

Liu FC, Nelson TW (2016) In-situ material flow pattern around probe during friction stir welding of austenitic stainless steel. Mater Des 110:354–364

Sabooni S, Karimzadeh F, Enayati MH et al (2015) Friction-stir welding of ultrafine grained austenitic 304L stainless steel produced by martensitic thermomechanical processing. Mater Des 76:130–140

Saeid T, Abdollah-zadeh A, Assadi H et al (2008) Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel. Mater Sci Eng 496:262–268

Nathan SR, Balasubramanian V, Malarvizhi S et al (2015) Effect of welding processes on mechanical and microstructural characteristics of high strength low alloy naval grade steel joints. Def Technol 11:308–317

Acknowledgements

The authors thank Department of Metallurgical and Material Engineering of Jadavpur University for providing the laboratory facilities and Ministry of Steel, GoI for providing necessary funding.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gain, S., Das, S.K., Sanyal, D., Acharyya, S. (2021). Effect of Process Parameters on Force Trends During Friction Stir Welding of AISI-316L Pipes. In: Ghosh, S.K., Ghosh, K., Das, S., Dan, P.K., Kundu, A. (eds) Advances in Thermal Engineering, Manufacturing, and Production Management. ICTEMA 2020. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-2347-9_24

Download citation

DOI: https://doi.org/10.1007/978-981-16-2347-9_24

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-2346-2

Online ISBN: 978-981-16-2347-9

eBook Packages: EngineeringEngineering (R0)