Abstract

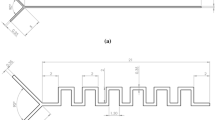

The microchannels play a crucial role in various lab-on-a-chip device. The performance of any microchannel is governed by the mixing characteristics and the pressure drop. This paper focusses on the comparative mixing performance analysis of serpentine microchannels with straight and curved bends. COMSOL Multiphysics 5 was used for performing the computational fluid dynamics (CFD) simulations. The aspect ratio (ratio of channel width to height) was varied as 0.75, 1, and 1.25. The inlet velocities at the two inlets were varied as 0.5, 0.75, and 1 mm/s. The microchannel width and height were 400 μm (for aspect ratio 1). The pressure variation (drop) and mixing within straight and curved serpentine microchannel is analyzed. The effect of inlet velocity on mixing length and pressure drop is studied. The influence of the aspect ratio on pressure drop is also investigated. It was noted that the pressure drop is enhanced with an increase in aspect ratio from 0.75 to 1.25

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lee CY, Wang WT, Liu CC, Fu LM (2016) Passive mixers in microfluidic systems: a review. Chem Eng J 288:146–160

Lim YC, Kouzani AZ, Duan W (2010) Lab-on-a-chip: a component view. Microsyst Technol 16(12):1995–2015

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442(7101):368–373

Bothe D, Stemich C, Warnecke HJ (2006) Fluid mixing in a T-shaped micro-mixer. Chem Eng Sci 61(9):2950–2958

Bahrami M, Yovanovich MM, Culham JR (2005) Pressure drop of fully-developed, laminar flow in microchannels of arbitrary cross-section In: International conference on nanochannels, microchannels, and minichannels, vol 41855, pp 269–280

Song H, Wang Y, Pant K (2012) Cross-stream diffusion under pressure-driven flow in microchannels with arbitrary aspect ratios: a phase diagram study using a three-dimensional analytical model. Microfluid Nanofluid 12(1–4):265–267

Ansari MA, Kim KY, Kim SM (2010) Numerical study of the effect on mixing of the position of fluid stream interfaces in a rectangular microchannel. Microsyst Technol 16(10):1757–1763

Gobby D, Angeli P, Gavriilidis A (2001) Mixing characteristics of T-type microfluidic mixers. J Micromech Microeng 11(2):126

Cortes-Quiroz CA, Azarbadegan A, Zangeneh M (2014) Evaluation of flow characteristics that give higher mixing performance in the 3-D T-mixer versus the typical T-mixer. Sens Actuators B: Chem 31(202):1209–1219

Lü Y, Zhu S, Wang K, Luo G (2016) Simulation of the mixing process in a straight tube with sudden changed cross-section. Chin J Chem Eng 24(6):711–718

Yang ID, Chen YF, Tseng FG, Hsu HT, Chieng CC (2006) Surface tension driven and 3-D vortex enhanced rapid mixing microchamber. J Microelectromech Syst 15(3):659–670

Sudarsan AP, Ugaz VM (2006) Fluid mixing in planar spiral microchannels. Lab Chip 6(1):74–82

Hossain S, Kim KY (2015) Mixing performance of a serpentine micromixer with non-aligned inputs. Micromachines 6(7):842–854

Gidde RR, Pawar PM, Ronge BP, Shinde AB, Misal ND, Wangikar SS (2019) Flow field analysis of a passive wavy micromixer with CSAR and ESAR elements. Microsyst Technol 25(3):1017–1030

Das SS, Tilekar SD, Wangikar SS, Patowari PK (2017) Numerical and experimental study of passive fluids mixing in micro-channels of different configurations. Microsyst Technol 23(12):5977–5988

Hong CC, Choi JW, Ahn CH (2004) A novel in-plane passive microfluidic mixer with modified Tesla structures. Lab Chip 4(2):109–113

**a G, Li J, Tian X, Zhou M (2012) Analysis of flow and mixing characteristics of planar asymmetric split-and-recombine (P-SAR) micromixers with fan-shaped cavities. Ind Eng Chem Res 51(22):7816–7827

Li J, **a G, Li Y (2013) Numerical and experimental analyses of planar asymmetric split-and-recombine micromixer with dislocation sub-channels. J Chem Technol Biotechnol 88(9):1757–1765

Tran-Minh N, Dong T, Karlsen F (2014) An efficient passive planar micromixer with ellipse-like micropillars for continuous mixing of human blood. Comput Meth Prog Biomed 117(1):20–29

Guo L, Xu H, Gong L (2015) Influence of wall roughness models on fluid flow and heat transfer in microchannels. Appl Therm Eng 84:399–408

Jain M, Rao A, Nandakumar K (2013) Numerical study on shape optimization of groove micromixers. Microfluid Nanofluid 15(5):689–699

Kim DS, Lee SW, Kwon TH, Lee SS (2004) A barrier embedded chaotic micromixer. J Micromech Microeng 14(6):798

Wangikar SS, Patowari PK, Misra RD (2018) Numerical and experimental investigations on the performance of a serpentine microchannel with semicircular obstacles. Microsyst Technol 24(8):3307–3320

Jadhav SV, Pawar PM, Wangikar SS, Bhostekar NN, Pawar ST (2020) Thermal management materials for advanced heat sinks used in modern microelectronics. IOP Conf Ser: Mater Sci Eng 814(1):012044

Wangikar SS, Patowari PK, Misra RD (2017) Effect of process parameters and optimization for photochemical machining of brass and german silver. Mater Manuf Processes 32(15):1747–1755

Wangikar SS, Patowari PK, Misra RD (2016) Parametric optimization for photochemical machining of copper using grey relational method. In: Techno-societal 2016, International conference on advanced technologies for societal applications. Springer, Cham, pp 933–943

Wangikar SS, Patowari PK, Misra RD (2018) Parametric optimization for photochemical machining of copper using overall evaluation criteria. Mater Today: Proc 5(2):4736–4742

Wangikar SS, Patowari PK, Misra RD, Misal ND (2019) Photochemical machining: a less explored non-conventional machining process. In: Non-conventional machining in modern manufacturing systems. IGI Global, pp 188–201

Chavan NV, Bhagwat RM, Gaikwad SS, Shete SS, Kashid DT, Wangikar SS (2019) Fabrication and characterization of microfeatures on PMMA using CO2 laser machining. Int J Trends Eng Technol 36:29–32

Kulkarni HD, Rasal AB, Bidkar OH, Mali VH, Atkale SA, Wangikar SS, Shinde AB (2019) Fabrication of micro-textures on conical shape hydrodynamic journal bearing. Int J Trends Eng Technol 36(1):37–41

Raut MA, Kale SS, Pangavkar PV, Shinde SJ, Wangikar SS, Jadhav SV, Kashid DT (2019) Fabrication of micro channel heat sink by using photo chemical machining. Int J New Technol Res 5(4):72–75

Jadhav SV, Pawar PM, Shinde AB, Wangikar SS (2020) Performance analysis of elliptical pin fins in the microchannels. In: Techno-societal 2018. Springer, Cham, pp 295–304

Bhagwat RM, Gaikwad SS, Shete SS, Chavan NV, Wangikar SS (2020) Study of etchant concentration effect on the edge deviation for photochemical machining of copper. Novyi MIR Res J 5(9):38–44

Patil PK, Kulkarni AM, Bansode AA, Patil MK, Mulani AA, Wangikar SS (2020) Fabrication of logos on copper material employing photochemical machining. Novyi MIR Res J 5(7):70–73

Kame MM, Sarvagod MV, Namde PA, Makar SC, Jadhav SV, Wangikar SS (2020) Fabrication of microchannels having different obstacles using photo chemical machining process. Novyi MIR Res J 5(6):27–32

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wangikar, S.S., Patowari, P.K., Misra, R.D., Gidde, R., Jadhav, S., Sonawane, S. (2021). Mixing Performance Analysis of Serpentine Microchannels with Straight and Curved Bends. In: Bag, S., Paul, C.P., Baruah, M. (eds) Next Generation Materials and Processing Technologies. Springer Proceedings in Materials, vol 9. Springer, Singapore. https://doi.org/10.1007/978-981-16-0182-8_9

Download citation

DOI: https://doi.org/10.1007/978-981-16-0182-8_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0181-1

Online ISBN: 978-981-16-0182-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)