Abstract

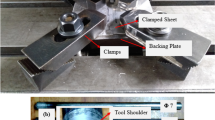

In the present work, the effect of selected welding conditions on the temperature evolution, springback behaviour and formability of friction-stir welding (FSW) sheets is investigated. The Al6061T6-Al6061T6 combination is used for temperature evolution studies, while dissimilar Al combination made of Al6061T6 and Al5052H32 is used in springback and formability tests. The springback experiments are performed with a V-bending set-up without tension, and formability experiments are conducted using a limiting dome height (LDH) set-up. By increasing the shoulder diameter, plunge depth and tool rotation speed, the peak temperature is increased, and it is vice versa for welding speed. In the case of springback, the performance of FSW sheets is in between that of Al6061T6 and Al5052H32 base materials. Reduction in springback of FSW sheets is observed at higher rotational speed and welding speed, and this is correlating well with the modifications in tensile properties such as yield strength to elastic modulus ratio and strain hardening exponent of the weld zone (WZ) with varying FSW conditions. Three different modes of failures, normal and parallel to the WZ, are observed during formability testing of FSW sheets made of dissimilar Al grades at two different strain-paths. It is better to evaluate the forming limit of FSW sheets at individual strain-paths, rather than in all the strain-paths using a forming limit curve (FLC), because of changing failure pattern with changing strain-paths.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Alves de Sousa RJ, Correia JPM, Simoes FJP, Ferreira JAF, Cardoso RPR, Gracio JJ, Barlat F (2008) Unconstrained springback behavior of Al–Mg–Si sheets for different sitting times. Int J Mech Sci 50:1381–1389

Chang SH, Shin JM, Heo YM, Se DG (2002) Springback characteristics of the tailor-welded strips in U-bending. J Mater Process Technol 130–131:14–19

Durga Rao B, Narayanan RG (2014) Springback of friction-stir welded sheets made of aluminium grades during V-bending: an experimental study. ISRN Mech Eng Article ID 681910. doi:10.1155/2014/681910

Garcia-Romeu ML, Ciurana J, Ferrer I (2007) Springback determination of sheet metals in an air bending process based on an experimental work. J Mater Process Technol 191:174–177

Greeze R, Manach PY, Laurent H, Thuillier S, Menezes LF (2010) Influence of the temperature on residual stresses and springback effect in an aluminium alloy. Int J Mech Sci 52:1094–1100

Kim J, Lee W, Chung KH, Kim D, Kim C, Okamoto K, Wagoner RH, Chung K (2011) Springback evaluation of friction-stir welded TWB automotive sheets. Met Mater Int 17:83–98

Lee W, Chung KH, Kim D, Kim J, Kim C, Okamoto K, Wagoner RH, Chung K (2009) Experimental and numerical study on formability of friction-stir welded TWB sheets based on hemispherical dome stretch tests. Int J Plast 25:1626–1654

Lim H, Lee MG, Sung JH, Kim JH, Wagoner RH (2012) Time-dependent springback of advanced high strength steels. Int J Plast 29:42–59

Miles MP, Mahoney MW, Fuller CB (2006) Prediction of bending limits in friction-stir-processed thick plate aluminum. Metall Mater Trans A 37A:399–404

Mishra RS, Ma ZY (2005) Friction-stir welding and processing. Mater Sci Eng R 50:1–78

Moon YH, Kang SS, Cho JR, Kim TG (2003) Effect of tool temperature on the reduction of the springback of aluminum sheets. J Mater Process Technol 132:365–368

Mulder J, Vegter Henk, ** ** Ha, van den Boogaard AH (2012) Determination of flow curves under equibiaxial stress conditions. Key Eng Mater 53:504–506

Park S, Lee CG, Kim J, Han HN, Kim SJ, Chung K (2008) Improvement of formability and springBack of AA5052-H32 sheets based on surface friction-stir method. J Eng Mater Technol 130: 041007-1–041007-10

Ramulu PJ, Ganesh Narayanan R, Kailas SV, Reddy J (2013a) Internal defect and process parameter analysis during friction-stir welding of Al 6061 sheets. The Int J Adv Manufact Technol 65: 1515–1528

Ramulu PJ, Kailas Satish V, Ganesh Narayanan R (2013b) Influence of tool rotation speed and feed rate on the forming limit of friction-stir welded AA6061-T6 sheets. Proc Inst Mech Eng Part C: J Mech Eng Sci 227:520–541

Wang JF, Wagoner RH, Carden WD, Matlock DK, Barlat F (2004) Creep and anelasticity in the springback of aluminium. Int J Plast 20:2209–2232

Wang L, Huang G, Zhang H, Wang Y, Yin L (2013) Evolution of springback and neutral layer of AZ31B magnesium alloy V-bending under warm forming conditions. J Mater Process Technol 213:844–850

Woo W, Balogh L, Ungár T, Choo H, Feng Z (2008) Grain structure and dislocation density measurements in a friction-stir welded Aluminum alloy using X-ray peak profile analysis. Mater Sci Eng A 498:308–313

Zadpoor AA, Sinke J, Benedictus R, Pieters R (2008) Mechanical properties and microstructure of friction-stir welded tailor-made blanks. Mater Sci Eng A 494:281–290

Zadpoor AA, Sinke J, Benedictus R (2009) Finite element modeling and failure prediction of friction-stir welded blanks. Mater Des 30:1423–1434

Acknowledgments

R. Ganesh Narayanan acknowledges DST, India and ARDB, India for sponsoring the projects. The present work is part of those projects.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this paper

Cite this paper

Katre, S., Karidi, S., Durga Rao, B., Ramulu, P.J., Narayanan, R.G. (2015). Springback and Formability Studies on Friction Stir Welded Sheets. In: Narayanan, R., Dixit, U. (eds) Advances in Material Forming and Joining. Topics in Mining, Metallurgy and Materials Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2355-9_7

Download citation

DOI: https://doi.org/10.1007/978-81-322-2355-9_7

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2354-2

Online ISBN: 978-81-322-2355-9

eBook Packages: EngineeringEngineering (R0)