Abstract

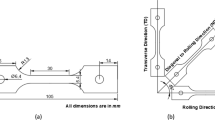

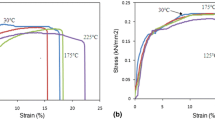

The objective of this study was to focus on the current state of finite element methods with respect to reliability in modeling of sheet metal forming processes. The trustworthiness of the FE simulations largely depends on the input material models used and correctness of the input material data. Formability parameters required for finite element analysis have been determined for Ti–6Al–4V alloy at temperature ranging from room temperature to 400 °C at intervals of 50 °C. Based on these formability parameters, various anisotropic yield criteria, namely, von-Mises, Hill 1948, Barlat 1989, Barlat 1996 and Cazacu–Barlat, have been implemented for Ti–6Al–4V alloy. In addition to that, circular deep drawing experiments have been performed in order to study the formability of Ti–6Al–4V alloy sheet at warm condition. It has been observed that formability of the material is very poor at room temperature. At temperatures above 150 °C till 400 °C, the limiting drawing ratio is found to be 1.8, which is substantially lesser than other structural alloys. Additionally, in the properly drawn cups, thickness distribution and earing tendency have been studied over the range of temperature. In order to validate the experimental results, finite element analysis has been done using commercially available software DYNAFORM version 5.6.1 with LSDYNA solver version 971. Also, failure regions during the experimentation have been identified using FE analysis. Comparison of yield criteria based on thickness distribution, earing profile, complexity in material parameter identification, and computational time has shown Cazacu–Barlat to be well suited for deep drawing of Ti–6Al–4V alloy.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abedrabbo N, Pourboghrat F, Carsley J (2007) Forming of AA 5182-O and AA 5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int J Plast 23:841–875

Altan T, Oh SI, Gegel HL (1983) Metal forming: fundamentals and applications. Am Soc Met 1:4–10

Atkinson M (1996) Accurate determination of biaxial stress–strain relationships from hydraulic bulging tests of sheet metals. Int J Mech Sci 39(7):761–769

Banabic D (2010) Sheet metal forming process: constitutive modeling and numerical simulations. Springer, Heidelberg

Barlat F, Lian J (1989) Plastic behaviour and strechability of sheet metals Part I: a yield function for orthotropic sheets under plane stress condition. Int J Plast 5:51–56

Barlat F, Brem JC et al (2003) Plane stress yield function for aluminium alloy sheet. Part 1 theory. Int J Plast 19:1297–1319

Beal JD, Boyer R, Sanders D (2006) The boeing company forming of titanium and titanium alloys. Metalworking Sheet Form 14 (ASM Handbook): 656–669

Bergström Y (1983) The plastic deformation of metals—a dislocation model and its applicability. Rev Powder Metall Phys Ceram 2:105–115

Bolt PJ, Lamboo NAPM, Rozier PJCM (2001) Feasibility of warm drawing of aluminum products. J Mater Process Technol 115:118–121

Bong HJ, Barlat F et al (2013) Formability of austenitic and ferritic stainless steels at warm forming temperature. Int J Mech Sci 75:94–109

Cazacu O, Plunkett B, Barlat F (2006) Orthotropic yield criterion for hexagonal closed packed metals. Int J Plast 22:1171–1194

Cole GS, Sherman AM (1995) Lightweight materials for automotive applications. Mater Charact 35:3–9

Davis JR (ed) (2004) Tensile testing, 2nd edn. ASM International, Ohio

Demmerle S, Boehler JP (1993) Optimal design of biaxial tensile cruciform specimens. J Mech Phys Solids 41(1):143–181

Djavanroodi F, Derogar A (2010) Experimental and numerical evaluation of forming limit diagram for Ti-6Al-4V titanium and Al6061-T6 aluminum alloys sheets. Mater Des 31:4866–4875

EI-Domiaty A (1992) The effect of strain, strain rate and temperature on formability of Ti-6Al-4V alloy. J Mater Process Technol 32:243–251

Güner A, Brosius A, Tekkaya AE (2009) Analysis of the hydraulic bulge test with FEA concerning the accuracy of the determined flow curves. Key Engineering Materials 410:439–447

Gupta AK, Anirudh VK, Singh SK (2013) Constitutive models to predict flow stress in austenitic stainless steel 316 at elevated temperatures. Mater Des 43:410–418

Gutscher G, Wu HC, Ngaile G, Altan T (2004) Determination of flow stress for sheet metal forming using the viscous pressure bulge (VPB) test. J Mater Process Technol 146:1–7

Hannon A, Tiernan P (2008) A review of planer biaxial tensile test system for sheet metal. J Mater Process Technol 198:1–13

Hill R (1950) The mathematical theory of plasticity. Clarendon, Oxford

Hollomon JH (1945) Trans AIME 162:268–290

Hosford W, Canddell R (2014) Metal forming mechanics and metallurgy, 3rd edn. Cambridge University Press, Cambridge, pp 52–75

Hussaini SM, Singh SK, Gupta AK (2014) Experimental and numerical investigation of formability for austenitic stainless steel 316 at elevated temperatures. J Mater Res Technol 3(1):17–24

Kaya S, Altan T, Groche P, Klöpsch C (2008) Determination of the flow stress of magnesium AZ31-O sheet elevated temperatures using hydraulic bulge test. Int J Mach Tools Manuf 48:550–557

Keefe AC, Carman GP, Jardine P (1998) Torsional behavior of shape memory alloys. Smart Struct Mater 3324:58–67

Keum YT, Ghoo BY, Waginer RH (2001) 3-Dimensional finite element analysis of non-isothermal forming processes for non-ferrous sheets. Simulation of materials processing: theory, methods and applications. A.A. Balkema, Lisse, pp 813–818

Koç Muammer, Billur Eren, Cora Ömer Necati (2011) An experimental study on the comparative assessment of hydraulic bulge test analysis methods. Mater Des 32:272–281

Kotkunde N, Deole AD et al (2014a) Failure and formability studies in warm deep drawing of Ti–6Al–4V alloy. Mater Des 60:540–547

Kotkunde N, Deole AD et al (2014b) Experimental and numerical investigation of anisotropic yield criteria for warm deep drawing of Ti–6Al–4V alloy. Mater Des 63:336–344

Kotkunde N, Krishnamurthy HN et al (2014c) Microstructure study and constitutive modeling of Ti–6Al–4V alloy at elevated temperatures. Mater Des 54:96–103

Kotkunde N, Deole AD et al (2014d) Comparative study of constitutive modeling for Ti–6Al–4V alloy at low strain rates and elevated temperatures. Mater Des 55:999–1005

Kurukuri S, van den Boogaard AH et al (2009) Warm forming simulation of Al–Mg sheet. J Mater Process Technol 209:5636–5645

Lange K (1985) Handbook of metal forming. McGraw-Hill, New York

Lee JY, Xu L, Barlat F et al (2013) Balanced biaxial testing of advanced high strength steels in warm conditions. J Exp Mech 53(9):1681–1692

Lin YC, Chen X-M (2011) A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des 32:1733–1759

LS-DYNA Keyword User’s Manual (2007) Volume 1, Livermore Software Technology Corporation (LSTC). (http://lstc.com/pdf/ls-dyna_971_manual_k.pdf)

Ludwik P (1909) Elemente der Technologischen Mechanik. Verlag Von Julius Springer, Leipzig, p 32

Marciniak Z (2002) Mechanics of sheet metal forming. Butterworth-Heinemann, Oxford

Marciniak Z, Kuczyński K, Pokora T (1973) Influence of the plastic properties of a material on the forming limit diagram for sheet metal in tension. Int J Mech Sci 15(10):789–800

Mishra NS, Mishra S, Ramaswamy V (1989) Analysis of the temperature dependence of strain-hardening behavior in high-strength steel. Metall Trans A 20:2819

Naka T, Yoshida F (1999) Deep drawability of type 5083 aluminum–magnesium alloy sheet under various conditions of temperature and forming speed. J Mater Process Technol 89(90):19–23

Nielsen KB (2000) sheet metal forming simulation using explicit finite element methods, 3rd edition, Aalborg University, Denmark

Odenberger E-L, Schill M, Oldenburg M (2013) Thermo-mechanical sheet metal forming of aero engine components in Ti–6Al–4V—part 2: constitutive modelling and validation. Int J Mater Form 6:403–416

Olovsson L, Simonsson K, Unosson M (2005) Selective mass scaling for explicit finite element analyses. Int J Numer Meth Eng 63(10):1436–1445

Pearce R (1968) Some aspects of anisotropic plasticity in sheet metals. Int J Mech Sci 10(12):995–1004

Singh SK, Mahesh K et al (2010) Understanding formability of extra-deep drawing steel at elevated temperature using finite element simulation. Mater Des 31:4478–4484

Swift HW (1952) Plastic instability under plane stresses. J Mech Phys Solids 1:1–18

Takuda H, Mori K et al (2003) Finite element analysis of the formability of an austenitic stainless steel sheet in warm deep drawing. J Mater Process Technol 143:242–248

Toros S, Ozturk F, Kacar I (2008) Review of warm forming of aluminum–magnesium alloys. J Mater Process Technol 207:1–12

Van den Boogaard AH, Huétink J (2006) Simulation of aluminium sheet forming at elevated temperatures. Comput Methods Appl Mech Eng 195:6691–6709

Vlassak JJ, Nix WD (1992) A new bulge test technique of Young’s modulus and Poisson’s ratio of thin films. J Mater Res 7(12):3242–3249

Voce E (1948) J Inst Met 74:537–562

Wessel JK (2004) Handbook of advanced materials Hoboken. Wiley, Hoboken

Wierzbicki T, Bao Y et al (2005) Calibration and evaluation of seven fracture models. Int J Mech Sci 47(4–5):719–743

**ang-Dong W, Wan M, **an-Bin Z (2005) Biaxial tensile testing of cruciform specimen under complex loading. J Mater Process Technol 168:181–183

Zhang SH et al (2007) Deep-drawing of magnesium alloy sheets at warm temperatures. J Mater Process Technol 185:147–151

Acknowledgments

The financial support received for this research work from Department of Science and Technology (DST), Government of India, SERB-DST, SR/FTP/ETA-0056/2011 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this paper

Cite this paper

Kotkunde, N., Deole, A.D., Gupta, A.K., Singh, S.K. (2015). Numerical Analysis of Warm Deep Drawing for Ti–6Al–4V Alloy . In: Narayanan, R., Dixit, U. (eds) Advances in Material Forming and Joining. Topics in Mining, Metallurgy and Materials Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2355-9_6

Download citation

DOI: https://doi.org/10.1007/978-81-322-2355-9_6

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2354-2

Online ISBN: 978-81-322-2355-9

eBook Packages: EngineeringEngineering (R0)