Abstract

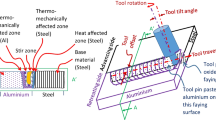

Manufacturing of the ever smaller components, be it mechanical, electronic, etc., is being chased now a days. Likewise in friction stir welding (FSW), when the thickness of the joining plates is reduced to less than 1 mm, i.e. micro-friction stir welding (µFSW), the application areas relate to joining thin-walled structures in electrical, electronic and micro-mechanical assemblies and in the packaging industry. The advantages of FSW like it being a solid state process, it not requiring any shielding gases or fluxes and its possibility to weld dissimilar and different thickness alloys emphasize the use of it to weld micro-thickness plates. In the present work, commercial grade AA6XXX series aluminium alloys of thickness 0.44 mm have been welded together in both butt and lap fashion. Tests have been conducted to measure the joint’s tensile strength (by conducting both transverse and longitudinal tension tests) and the micro-hardness. The use of lap welds in application areas of µFSW has been established.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Buffa G, Campanile G, Fratini L, Prisco A (2009) A friction stir welding of lap joints: influence of process parameters on the metallurgical and mechanical properties. J Mater Sci Eng A 519:19–26

Elangovan K, Balasubramanian V (2007) Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. J Mater Sci Eng A 459:7–18

Fujii H, Cui L, Maeda M, Nogi K (2006) Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminium alloys. J Mater Sci Eng A 419:25–31

Hirata T, Oguri T, Hagino H et al (2007) Influence of friction stir welding parameters on grain size and formability in 5083 aluminum alloy. J Mater Sci Eng A 456:344–349

Lakshminarayanan K, Balasubramanian V (2008) Process parameters optimization for friction stir welding of RDE-40 aluminum alloy using Taguchi technique. Trans Nonferrous Met Soc China 18:548–554

Nishihara T, Nagasaka Y (2004) Development of micro-FSW. In: Proceedings of the 5th international friction stir welding symposium Metz, France, 14–16 Sept 2004

Parida B, Mohapatra MM, Biswas P (2014) Effect of tool geometry on mechanical and micro-structural properties of friction stir welding of Al-alloy, Int J Curr Eng Technol, Special Issue 2, pp 88–92

Peel M, Steuwer A, Preuss M, Withers PJ (2003) Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater 51:4791–4801

Salari E, Jahazi M, Khodabandeh A, Ghasemi-Nanesa H (2014) Influence of tool geometry and rotational speed on mechanical properties and defect formation in friction stir lap welded 5456 aluminium alloy sheets. J Mater Des 58:381–389

Sattari S, Bisadi H, Sajed M (2012) Mechanical properties and temperature distributions of thin friction stir welded sheets of AA5083. Int J Mech Appl 2(1):1–6

Scialpi A, De Giorgi M, De Filippis LAC, Nobile R, Panella FW (2007) Mechanical analysis of ultra-thin friction stir welding joined sheets with dissimilar and similar materials. J Mater Des 29:928–936

Scialpi A, De Fillipis LAC, Cuomo P, Di Summa P (2008) Micro friction stir welding of 2024-6082 aluminium alloys. Weld Int 22(1):16–22

Vijayan S, Raju R, Rao SRK (2010) Multiobjective optimization of friction stir welding process parameters on aluminium alloy AA 5083 using Taguchi-based grey relation analysis. Mater Manuf Process 25(11):1206–1212

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this paper

Cite this paper

Ahmed, S., Shubhrant, A., Deep, A., Saha, P. (2015). Development and Analysis of Butt and Lap Welds in Micro-friction Stir Welding (µFSW). In: Narayanan, R., Dixit, U. (eds) Advances in Material Forming and Joining. Topics in Mining, Metallurgy and Materials Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2355-9_15

Download citation

DOI: https://doi.org/10.1007/978-81-322-2355-9_15

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2354-2

Online ISBN: 978-81-322-2355-9

eBook Packages: EngineeringEngineering (R0)