Abstract

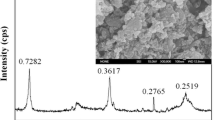

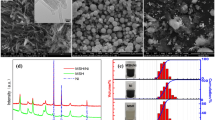

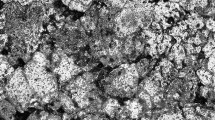

A kind of composite powder mixed serpentine with silica is used as lubricant additive in this paper. The tribological property of 1045 steel pairs lubricated with composite additive oil was studied using an AMSLER friction and wear tester. The surface topographies and composition of the worn surface of 1045 steel rings were analyzed by SEM and XPS. The experimental results show that the composite additive can achieve an ultra low friction coefficient of 0.007 for the 1045 steel friction pairs. The worn surface is smooth with only a small amount of scratches on the local area. The XPS result after 100h test shows the carbon was concentrated on the worn surface besides Fe, O, Si and Mg. The existence of the carbon-rich surface layer is the main reason for the superlubricity characteristics.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

A. Hernandez Battez, J.E. Fernandez Rico, A. Navas Arias, et al. 2006, “The tribological behaviour of ZnO nanoparticles as an additive to PAO6,” Wear, 261, pp.256–263.

Wang L B, Wang B, Wang X B, et al. 2007, “Tribological investigation of CaF2 nanocrystals as grease additives” Tribology International, 40, pp.1179–1185.

Chen S, Liu W M. 2006, “Oleic acid capped PbS nanoparticles: Synthesis, characterization and tribological properties,” Materials Chemistry and Physics, 98, pp.183–189.

Yu Y, Gu J L, Kang F Y, et al. 2007, “surface restoration induced by lubricant additive of natural minerals,” Applied Surface Science, 253, pp.7549–7553.

Qi X W, Yang Y L, Fan B L. 2007, “Influence and mechanism of the formation of self-repair coatings with magnesium silicate hydroxide powder additives of different concentration,” Lubrication engineering (in chinese), 32(6), pp.46–49.

Chen W G, Gao Y Z, Zhang H C, et al. 2008, “Influence of heat-treated serpentine powder on wear properties of metal surface,” Journal of the chinese ceramic society, 36(1), pp.30–34.

Gao Y Z, Zhang H C, Xu X L, et al. 2006, “Formation mechanism of self-repair coatings on the worn metal surface using silicate particles as lubricant oil additive,” Lubrication Engineering (in chinese), 10, pp.39–42.

Chen W G, Gao Y Z, Zhang H C. 2007, “Research on Heat Treatment of the Self-repairing Additive and its Dispersibility,” Lubrication engineering (in chinese), 32(8), pp.52–55.

Ouyang J M, Bai Y, Yu G, et al. 2004, “XPS Spectra of Langmuir Blodgett Films and Their Electroluminescence,” Spectroscopy and Spectral Analysis (in chinese), 24(4), pp.499–501.

Huang W D, Zhan R J. 2003, “Raman Spectra and XPS Analyses of the Diamond like Carbon Film Deposited by Surface Wave Plasma,” Spectroscopy and Spectral Analysis (in chinese), 23(3), pp.512–514.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2009 Tsinghua University Press, Bei**g and Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Gao, Y., Chen, W., Zhang, H. (2009). Superlubricity Characteristics Using Ceramic Composite Mineral Powder as Lubricating Oil Additive. In: Luo, J., Meng, Y., Shao, T., Zhao, Q. (eds) Advanced Tribology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-03653-8_103

Download citation

DOI: https://doi.org/10.1007/978-3-642-03653-8_103

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-03652-1

Online ISBN: 978-3-642-03653-8

eBook Packages: EngineeringEngineering (R0)