Abstract

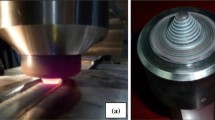

There are several friction welding procedures that have, to a greater or lesser extent, a commercial application, among which can be distinguished FSW - Friction Stir Welding. Firstly, using the FSW procedure, straight-line compounds were obtained, and soon afterwards also curvilinear, including circular. In addition to the great interest in the FSW process, many aspects of this process have not been sufficiently explored. This applies, inter alia, to the geometry of the tool. In this paper, the application of FSW welding to aluminium alloys is investigated, by varying different types of tool pin used during welding. Also, microstructure testing was performed, which was used for comparison and gradation of the quality of welds, welded with tools of different geometric shapes.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Koprivica, A., Vukčević, M., Spaić, O., Jokanović, M.: The influence of tool geometry on the microstructure of aluminum welded by FSW method. In: KODIP 2017, Budva, pp. 93–99 (2017). ISBN 978-9940-527-51-8

Vukčević, M., Šibalić, N., Spaić, O., Koprivica, A.: Tool geometry for the FSW process. In: KODIP 2015, Budva, pp. 169–175 (2015). ISBN 978-9940-669-01-0

Šibalić, N., Vukčević, M., Damjanović, M., Koprivica, A.: Examination of microstructure of welded joint of similar materials, obtained by FSW method. In: International Conference of Materials Processing Technology, MAPT 2017, Bangkok, Thailand, pp. 164–169 (2017). ISBN 978-974-456-785-7

Koprivica, A.: Welding aluminum alloys using the FSW procedure. Final Work on the Second Cycle of Studies, University of East Sarajevo, Faculty of Production and Management Trebinje, Trebinje (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Koprivica, A., Šibalić, N., Vukčević, M., Jokanović, M. (2019). The Influence of the Tool Geometry on the Quality of the Weld in FSW Process. In: Karabegović, I. (eds) New Technologies, Development and Application. NT 2018. Lecture Notes in Networks and Systems, vol 42. Springer, Cham. https://doi.org/10.1007/978-3-319-90893-9_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-90893-9_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-90892-2

Online ISBN: 978-3-319-90893-9

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)