Abstract

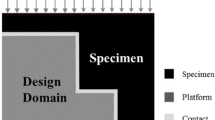

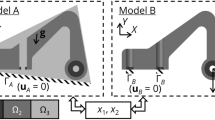

A series of strategies for designing support structure to fabricate overhanging features in additive manufacturing (AM) is proposed. The focus of this study is to maximize the external support stiffness while requiring supports that can be easily removed, minimizing the time required to add the supports, and using the least amount of material. These design requirements become necessities not only for adding supports to improve processing and post-processing efficiency, but also for reducing the cost of supports while maintaining specimen geometry. A repulsion index (RI) is proposed for satisfying the easy removal requirement and minimizing the size of artifacts left on the specimen surface; a weighting function is applied to quantify the time consumption to build the supports. The proposed RI and cost due to additional material and time consumption in adding the support are formulated within a multi-objective topological optimization constructed by the simple isotropic material with penalization method, continuous approximation of material distribution, and method of moving asymptotes. Numerical simulations demonstrated that rational and cost effective support layouts can be determined by the proposed cost-based formulation. This allows designers to find design solutions with a compromise between the deformation and the cost of support structure.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

AM Sub-Platform, European technology Sub-platform in Additive manufacturing, Additive Manufacturing: Strategic Research Agenda (2014). http://www.rm-platform.com/. Accessed 31 June 2016

Huang, Y., Leu, M.C., Mazumder, J., Donmez, A.: Additive manufacturing: current state, future potential, gaps and needs, and recommendations. J. Manufact. Sci. Eng. 137(1), 014001 (2015)

Gibson, I., Rosen, D., Stucker, B.: Additive Manufacturing Technologies. Springer, New York (2015)

Leary, M., Merli, L., Torti, F., Mazur, M., Brandt, M.: Optimal topology for additive manufacture: A method for enabling additive manufacture of support-free optimal structures. Mater. Des. 63, 678–690 (2014)

Gaynor, A.T., Guest, J.K.: Topology optimization considering overhang constraints: eliminating sacrificial support material in additive manufacturing through design. Struct. Multidiscip. Optim. 54, 1157–1172 (2016)

Langelaar, M.: An additive manufacturing filter for topology optimization of print-ready designs. Struct. Multidiscip. Optim. 55, 871–883 (2017)

Hu, K., **, S., Wang, C.C.: Support slimming for single material based additive manufacturing. Comput. Aided Des. 65, 1–10 (2015)

Mirzendehdel, A.M., Suresh, K.: Support structure constrained topology optimization for additive manufacturing. Comput. Aided Des. 81, 1–13 (2016)

Gilbert, E.N., Pollak, H.O.: Steiner minimal trees. SIAM J. Appl. Math. 16(1), 1–29 (1968)

Hwang, F.K., Richards, D.S.: Steiner tree problems. Networks 22(1), 55–89 (1992)

Vanek, J., Galicia, J.A.G., Benes, B.: Clever support: efficient support structure generation for digital fabrication. Comput. Graph. Forum 33(5), 117–125 (2014)

Strano, G., Hao, L., Everson, R.M., Evans, K.E.: A new approach to the design and optimisation of support structures in additive manufacturing. Int. J. Adv. Manufact. Technol. 66, 1247–1254 (2013)

Hussein, A., Hao, L., Yan, C., Everson, R., Young, P.: Advanced lattice support structures for metal additive manufacturing. J. Mater. Process. Technol. 213(7), 1019–1026 (2013)

Langelaar, M.: Topology optimization for additive manufacturing with controllable support structure costs. In: Papadrakakis, M., Papadopoulos, V., Stefanou, G., Plevris, V. (eds.) VII European Congress on Computational Methods in Applied Sciences and Engineering, ECCOMAS, Crete Island, Greece (2016)

Buhl, T.: Simultaneous topology optimization of structure and supports. Struct. Multidiscip. Optim. 23, 336–346 (2002)

Bendsøe, M.P., Sigmund, O.: Topology Optimization - Theory, Methods, and Applications. Springer, Heidelberg (2004)

Bendsøe, M.P., Sigmund, O.: Topology optimization. In: Arora, S.J. (ed.) Optimization of Structural and Mechanical Systems. World Scientific Publishing Co. Pte. Ltd., pp. 161–194 (2007)

Matsui, K., Terada, K.: Continuous approximation of material distribution for topology optimization. Int. J. Numer. Meth. Eng. 59(14), 1925–1944 (2004)

Acknowledgements

This work was supported by Ministry of Education and Ministry of Science and Technology, Taiwan, Republic of China under Contract No. MOST 105-2221-E-194-018 and MOST-106-2922-I-194-015.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Kuo, YH., Cheng, CC. (2018). Optimal External Support Structure Design in Additive Manufacturing. In: Schumacher, A., Vietor, T., Fiebig, S., Bletzinger, KU., Maute, K. (eds) Advances in Structural and Multidisciplinary Optimization. WCSMO 2017. Springer, Cham. https://doi.org/10.1007/978-3-319-67988-4_90

Download citation

DOI: https://doi.org/10.1007/978-3-319-67988-4_90

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-67987-7

Online ISBN: 978-3-319-67988-4

eBook Packages: EngineeringEngineering (R0)