Abstract

The Nuclear Regulatory Commission has identified chloride-induced stress corrosion cracking (CISCC) of austenitic stainless steel dry cask storage systems (DCSS) as an area of great concern. Friction stir processing (FSP) was used to repair laboratory-generated stress corrosion cracking (SCC) in representative stainless steel 304 coupons. Results of this study show FSP is a viable method for repair and mitigation CISCC. This paper highlights lessons learned and techniques developed to apply FSP to crack repair in sensitized thick section stainless steel 304. These include: development of process parameters, welding at low spindle speed, use of weld power and temperature control and optimization of these controls. NDE and destructive analysis are also presented to demonstrate effectiveness of the developed methods for SCC crack repair.

Similar content being viewed by others

References

Hanson B, Alsaed H, Stockman C, Enos D, Meyer R, Sorenson K (2012) Gap analysis to support extended storage of used nuclear fuel. http://www.energy.gov/sites/prod/files/Gap%20Analysis%20Rev%200%20Final.pdf

(2012) NRC INFORMATION NOTICE 2012-20: potential chloride-induced stress corrosion cracking of austenitic stainless steel and maintenance of dry cask storage system canisters. http://www.nrc.gov/docs/ML1231/ML12319A440.pdf

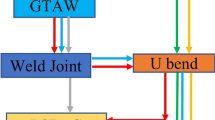

Sutton B, Ross K, Grant G, Cannell G, Frederick G, Couch R (2017) Friction stir processing of degraded austenitic stainless steel nuclear fuel dry cask storage system canisters. In: Friction stir weld and processing IX, San Diego

Marshall D, Sorensen C (2013) System parameter identification for friction stir processing. In: Friction stir welding and processing VII, San Antonio, TX

Ross KA, Sorensen CD (2013) Paradigm shift in control of the spindle axis. In: Friction stir welding and processing VII, San Antonio, TX

Cannell G, Grant G, Adams T (2015) Demonstration of friction stir welding (FSW) technology for packaging of used nuclear fuel. In: Waste management, Pheonix, Arizona

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Ross, K., Sutton, B., Grant, G., Cannell, G., Frederick, G., Couch, R. (2017). Development of Friction Stir Processing for Repair of Nuclear Dry Cask Storage System Canisters. In: Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D. (eds) Friction Stir Welding and Processing IX. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52383-5_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-52383-5_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52382-8

Online ISBN: 978-3-319-52383-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)