Abstract

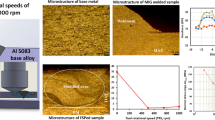

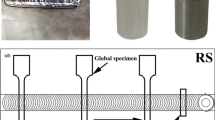

The main objective of this work is to investigate the microstructure and mechanical properties of friction stir welded 250 grade Maraging steel. Successful welds were made using W-25%Re-4%HfC pin tools in forge control mode at a rotational speed of 200 rev·min−1 and a travel speed of 50.8 mm·s−1. Retained austenite was identified in the weld nugget. Formation of retained austenite in the weld nugget is strongly influenced by the weld process parameters. The effects of post weld aging on the corrosion and mechanical properties of the welds were evaluated and compared to the parent material. Post-weld aging at 482 °C for 15 h resulted in peak hardness across the weld nugget.

Similar content being viewed by others

References

Shamantha C, Narayanan R, Iyer K, Radhakrishnan V, Seshadri S, Sundararajan S, Sundaresan S (2000) Microstructural changes during welding and subsequent heat treatment of 18Ni (250-grade) maraging steel. Mater Sci Eng, A 287(1):43–51

Blauel J, Smith H, Schulze G (1974) Fracture toughness study of a grade 300 maraging steel weld joint. Weld J Res Suppl 53:211

Rajkumar V, Arivazhagan N, Ramkumar KD (2014) Studies on welding of maraging steels. Procedia Eng 75:83–87

Höring S, Abou-Ras D, Wanderka N, Leitner H, Clemens H, Banhart J (2009) Characterization of reverted austenite during prolonged ageing of maraging steel CORRAX. Steel Res Int 80(1):84–88

Schnitzer R, Radis R, Nöhrer M, Schober M, Hochfellner R, Zinner S, Povoden-Karadeniz E, Kozeschnik E, Leitner H (2010) Reverted austenite in PH 13–8 Mo maraging steels. Mater Chem Phys 122(1):138–145

Viswanathan U, Dey G, Sethumadhavan V (2005) Effects of austenite reversion during overageing on the mechanical properties of 18 Ni (350) maraging steel. Mater Sci Eng, A 398(1):367–372

Fanton L, Abdalla AJ, Lima M (2014) Heat treatment and ybfiber laser welding of a maraging steel. Weld J 93:362–368

Tariq F, Baloch RA, Ahmed B, Naz N (2010) Investigation into microstructures of maraging steel 250 weldments and effect of post-weld heat treatments. J Mater Eng Perform 19(2):264–273

Ramana PV, Reddy GM, Mohandas T (2013) Microstructure, hardness and residual stress distribution in maraging steel gas tungsten arc weldments. Sci Technol Weld Joining

Quintino L, Costa A, Miranda R, Yapp D, Kumar V, Kong C (2007) Welding with high power fiber lasers–a preliminary study. Mater Des 28(4):1231–1237

Sakai P, Lima M, Fanton L, Gomes C, Lombardo S, Silva D, Abdalla A (2015) Comparison of mechanical and microstructural characteristics in maraging 300 steel welded by three different processes: LASER PLASMA and TIG. Procedia Eng 114:291–297

Meshram SD, Reddy GM, Pandey S (2013) Friction stir welding of maraging steel (Grade-250). Mater Des 49:58–64

Thompson BT (2010) Tool degradation characterization in the friction stir welding of hard metals. The Ohio State University

Jasthi BK, Arbegast WJ, Howard SM (2009) Thermal expansion coefficient and mechanical properties of friction stir welded invar (Fe-36% Ni). J Mater Eng Perform 18(7):925–934

Acknowledgements

The authors gratefully acknowledge the financial support provided by the National Science Foundation under the contract number 157074. The authors also acknowledge the graduate students (Sushma Karanam, Lukmon Aminu, Reeha Budatla, and Oladimeji Oladepo) for their help with the specimen preparation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Jasthi, B.K., Curtis, T., Widener, C.A., West, M., Kellogg, B. (2017). Effect of Thermal Aging on the Corrosion and Mechanical Properties of Friction Stir Welded 250 Grade Maraging Steel. In: Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D. (eds) Friction Stir Welding and Processing IX. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52383-5_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-52383-5_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52382-8

Online ISBN: 978-3-319-52383-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)