Abstract

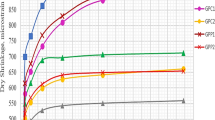

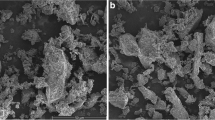

Cement is rapidly becoming among the extensively utilized materials. However, its production contributes to approximately 6–8% of the world’s CO2 emissions. Finding ways to reduce the carbon footprint of materials without increasing their cost is quite challenging. One technique to enhance sustainability is to produce alternative materials with low energy consumption, for instance geopolymer. The type of alkali activator, thermal curing environment, and the concentration of alkali hydroxide are only a few of the variables that may have an impact on the physical and mechanical characteristics of geopolymer. This study uses natural Moroccan pozzolan as an aluminosolicate source and sodium silicate as an alkaline solution to investigate the impacts of the curing conditions on the mechanical properties of the geopolymer binder. Natural Moroccan pozzolan is an easily available abandoned natural resource. Alkaline solution to binder ratio and Na2SiO3 to NaOH ratio were constant. Same pastes were produced following dissimilar curing conditions (curing at room temperature, in water at 20 ℃, oven curing 70 h at 60 ℃ and continuous curing at 200 ℃) and tested for compressive and flexural strengths assessed after 7 and 28 days. The test findings demonstrated a substantial relationship between compressive strength and curing conditions. By subjecting geopolymer to elevated curing temperatures, it is possible to achieve binders with exceptional strength properties due to the rapid geopolimerization.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Atiş, C.D., Görür, E.B., Karahan, O., Bilim, C., İlkentapar, S., Luga, E.: Very high strength (120MPa) class F fly ash geopolymer mortar activated at different NaOH amount, heat curing temperature and heat curing duration. Constr. Build. Mater. 96, 673–678 (2015). https://doi.org/10.1016/j.conbuildmat.2015.08.089

Duxson, P., Fernández-Jiménez, A., Provis, J.L., Lukey, G.C., Palomo, A., Van Deventer, J.S.J.: Geopolymer technology: the current state of the art. J. Mater. Sci. 42(9), 2917–2933 (2007). https://doi.org/10.1007/s10853-006-0637-z

Xu, M., He, Y., Liu, Z., Tong, Z., Cui, X.: Preparation of geopolymer inorganic membrane and purification of pulp-papermaking green liquor. Appl. Clay Sci. 168, 269–275 (2019). https://doi.org/10.1016/j.clay.2018.11.024

Bondar, D., Lynsdale, C.J., Milestone, N.B., Hassani, N., Ramezanianpour, A.A.: Effect of type, form, and dosage of activators on strength of alkali-activated natural pozzolans. Cement Concr. Compos. 33(2), 251–260 (2011). https://doi.org/10.1016/j.cemconcomp.2010.10.021

Yadollahi, M.M., Benli, A., Demirboğa, R.: The effects of silica modulus and aging on compressive strength of pumice-based geopolymer composites. Constr. Build. Mater. 94, 767–774 (2015). https://doi.org/10.1016/j.conbuildmat.2015.07.052

Haddad, R.H., Alshbuol, O.: Production of geopolymer concrete using natural pozzolan: a parametric study. Constr. Build. Mater. 114, 699–707 (2016). https://doi.org/10.1016/j.conbuildmat.2016.04.011

Vafaei, M., Allahverdi, A.: Influence of calcium aluminate cement on geopolymerization of natural pozzolan. Constr. Build. Mater. 114, 290–296 (2016). https://doi.org/10.1016/j.conbuildmat.2016.03.204

Djobo, J.N.Y., Elimbi, A., Tchakouté, H.K., Kumar, S.: Volcanic ash-based geopolymer cements/concretes: the current state of the art and perspectives. Environ. Sci. Pollut. Res. 24(5), 4433–4446 (2017). https://doi.org/10.1007/s11356-016-8230-8

Kantarcı, F., Türkmen, İ., Ekinci, E.: Optimization of production parameters of geopolymer mortar and concrete: a comprehensive experimental study. Constr. Build. Mater. 228, 116770 (2019). https://doi.org/10.1016/j.conbuildmat.2019.116770

Gultekin, A., Ramyar, K.: Investigation of high-temperature resistance of natural pozzolan-based geopolymers produced with oven and microwave curing. Constr. Build. Mater. 365, 130059 (2023). https://doi.org/10.1016/j.conbuildmat.2022.130059

Aziz et al. A.: Effect of acidic volcanic perlite rock on physio-mechanical properties and microstructure of natural pozzolan based geopolymers. Case Studies Constr. Mater. 15, e00712 (2021). https://doi.org/10.1016/j.cscm.2021.e00712

Aziz et al. A.: Effect of blast-furnace slag on physicochemical properties of pozzolan-based geopolymers. Mater. Chem. Phys. 258, 123880 (2021). https://doi.org/10.1016/j.matchemphys.2020.123880

Safari, Z., Kurda, R., Al-Hadad, B., Mahmood, F., Tapan, M.: Mechanical characteristics of pumice-based geopolymer paste. Resour., Conser. Recycl. 162, 105055 (2020). https://doi.org/10.1016/j.resconrec.2020.105055

Simou, S., Baba, K., Akkouri, N., Lamrani, M., Tajayout, M., Nounah, A.: Mechanical characterization and reinforcement of the adobe material of the chellah archaeological site. E3S Web Conf 150, 03022 (2020). https://doi.org/10.1051/e3sconf/202015003022

Simou, S., Baba, K., Akkouri, N., Lamrani, M., Tajayout, M., Nounah, A.: Mechanical characterization of the adobe material of the archaeological site of chellah. In: Ameen, H., Jamiolkowski, M., Manassero, M., Shehata, H. (eds.) Recent Thoughts in Geoenvironmental Engineering, in Sustainable Civil Infrastructures, pp. 118‑130. Cham: Springer International Publishing (2020). https://doi.org/10.1007/978-3-030-34199-2_8

Bourzik, O., Akkouri, N., Baba, K., Haddaji, Y., Nounah, A., Assafi, M., Bazzar, K.: Study of the effects of drinking water treatment sludge on the properties of class F fly ash-based geopolymer. Environ. Sci. Pollut. Res. Int. 29(58), 87668–87679 (2022). https://doi.org/10.1007/s11356-022-21873-9

Robayo-Salazar, R., Mejía-Arcila, J., Mejía De Gutiérrez, R., Martínez, E.: Life cycle assessment (LCA) of an alkali-activated binary concrete based on natural volcanic pozzolan: a comparative analysis to OPC concrete. Constr. Build. Mater. 176, 103–111 (2018). https://doi.org/10.1016/j.conbuildmat.2018.05.017

Yankwa Djobo, J.N., Elimbi, A., Tchakouté, H.K., Kumar, S.: Mechanical activation of volcanic ash for geopolymer synthesis: effect on reaction kinetics, gel characteristics, physical and mechanical properties. RSC Adv. 6(45), 39106–39117 (2016). https://doi.org/10.1039/C6RA03667H

Allahverdi, A., Mehrpour, K., Kani, E.N.: Investigating the possibility of utilizing pumice-type natural pozzonal in production of geopolymer cement (2008)

Lemougna, P.N., MacKenzie, K.J.D., Melo, U.F.C: Synthesis and thermal properties of inorganic polymers (geopolymers) for structural and refractory applications from volcanic ash. Ceram. Int. 37(8), 3011–3018 (2011). https://doi.org/10.1016/j.ceramint.2011.05.002

Tchakoute, H.K., Elimbi, A., Yanne, E., Djangang, C.N.: Utilization of volcanic ashes for the production of geopolymers cured at ambient temperature. Cem. Concr. Compos. 38, 75–81 (2013). https://doi.org/10.1016/j.cemconcomp.2013.03.010

Djobo, J.N.Y., Elimbi, A., Tchakouté, H.K., Kumar, S.: Reactivity of volcanic ash in alkaline medium, microstructural and strength characteristics of resulting geopolymers under different synthesis conditions. J. Mater. Sci. 51(22), 10301–10317 (2016). https://doi.org/10.1007/s10853-016-0257-1

Robayo-Salazar, R.A., De Gutiérrez, M., Puertas, F.: Study of synergy between a natural volcanic pozzolan and a granulated blast furnace slag in the production of geopolymeric pastes and mortars. Constr. Build. Mater. 157, 151–160 (2017). https://doi.org/10.1016/j.conbuildmat.2017.09.092

Hassan, A., Arif, M., Shariq, M.: Effect of curing condition on the mechanical properties of fly ash-based geopolymer concrete. SN Appl. Sci. 1(12), 1694 (2019). https://doi.org/10.I007/s42452-019-1774-8

Firdous, R., Stephan, D., Djobo, J.N.Y.: Natural pozzolan based geopolymers: a review on mechanical, microstructural and durability characteristics. Constr. Build. Mater. 190, 1251–1263 (2018). https://doi.org/10.1016/j.conbuildmat.2018.W.191

Villa, C., Pecina, E.T., Torres, R., Gómez, L.: Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 24(11), 2084–2090 (2010). https://doi.org/10.101d/j.conbui1dmat.2D10.04.052

Najafi Kani, E., Allahverdi, A.: Effects of curing time and temperature on strength development of inorganic polymeric binder based on natural pozzolan. J. Mater. Sci. 44, 3088–3097 (2009). https://doi.org/10.1007/s10853-3811-1

Takeda, H., Hashimoto, S., Kanie, H., Honda, S., Iwamoto, Y.: Fabrication and characterization of hardened bodies from Japanese volcanic ash using geopolymerization. Ceramics Int. 40(3), 4071–4076 (2014). https://doi.org/10.1016/j.ceramint.2D13.08.061

Tchakoute, H.K., Elimbi, A., Kenne, B.D., Mbey, J.A., Njopwouo, D.: Synthesis of geopolymers from volcanic ash via the alkaline fusion method: Effect of Al2O3/Na2O molar ratio of soda–volcanic ash. Ceramics Int. 39(1), 269–276 (2013). https://doi.org/10.101Wj.ceramint.2012.06.021

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Doughmi, K., Baba, K. (2023). Effect of Curing Conditions on the Mechanical Properties of Geopolymer Binder Based Natural Moroccan Pozzolan. In: Baba, K., Ouadif, L., Nounah, A., Bouassida, M. (eds) Advances in Research in Geosciences, Geotechnical Engineering, and Environmental Science. GeoME 2023. Springer Proceedings in Earth and Environmental Sciences. Springer, Cham. https://doi.org/10.1007/978-3-031-49345-4_22

Download citation

DOI: https://doi.org/10.1007/978-3-031-49345-4_22

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-49344-7

Online ISBN: 978-3-031-49345-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)