Abstract

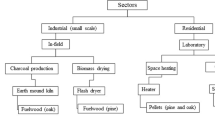

The industrial sector, the world’s largest energy consuming end-user, is a major greenhouse gas emitter. It heavily relies on fossil fuels, with only a small contribution from renewables, and of these, only biomass (mainly primary solid biofuels) is not marginal at a global scale. Several factors contribute to the limited adoption of renewables within the industry. The sector’s extraordinary diversity and complexity make a one-size-fits-all solution impossible. Industrial energy consumption varies significantly among different sub-sectors and even within each sub-sector, depending on production composition and industrial processes. Energy-intensive industries typically consume substantial amounts of process heat, while non-energy-intensive ones tend to rely more on electricity. Given the importance of energy-intensive industrial sub-sectors, finding solutions to decarbonise process heat is crucial. Process heat encompasses various applications, technologies, energy sources, temperatures and delivery methods. There is substantial demand for high-temperature process heat (>500 °C), with only a limited number of renewable energy options available, including bioenergy. Bioenergy holds the potential to contribute to the decarbonisation of industry but requires tailored solutions for each sub-sector and context. This chapter presents key commercially available biomass heat production systems, which vary in configuration, technologies and scale, with similarities to district heating systems, also discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

Note that these figures exclude the non-energy use of fossil fuels (for example, the fuels used as feedstocks to make products such as plastics and chemicals or bitumen used as road surface).

- 2.

OECD stands for Organisation for Economic Cooperation and Development.

- 3.

In 2020, these three sectors accounted for almost 60% of the world industrial energy consumption and more than 70% of the industrial CO2 emissions [33]. The emissions from industrial processes are included in this value, which for some industrial processes (e.g., cement and lime production) are important [34].

References

IEA (2022) Energy statistics data browser. https://www.iea.org/data-and-statistics/data-tools/energy-statistics-data-browser. Accessed 8 May 2023

Paltsev S, Morris J, Kheshgi H, Herzog H (2021) Hard-to-abate sectors: the role of industrial carbon capture and storage (CCS) in emission mitigation. Appl Energy 300:117322. https://doi.org/10.1016/j.apenergy.2021.117322

Kesicki F, Yanagisawa A (2015) Modelling the potential for industrial energy efficiency in IEA’s world energy outlook. Energ Effi 8:155–169. https://doi.org/10.1007/s12053-014-9273-7

Malico I, Nepomuceno Pereira R, Gonçalves AC, Sousa AMO (2019) Current status and future perspectives for energy production from solid biomass in the European industry. Renew Sustain Energy Rev 112:960–977. https://doi.org/10.1016/j.rser.2019.06.022

Seyboth K, Beurskens L, Langniss O, Sims REH (2008) Recognising the potential for renewable energy heating and cooling. Energy Policy 36:2460–2463. https://doi.org/10.1016/j.enpol.2008.02.046

European Commission (2016) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. An EU strategy on heating and cooling. European Commission, Brussels, Belgium

Union E (2018) Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources. Off J Eur Union L328:82–209

Tilia, TU Wien, IREES, et al (2022) District heating and cooling in the European Union. Overview of markets and regulatory frameworks under the revised Renewable Energy Directive. European Commission, Brussels, Belgium

Trinomics, Öko-Institut, DTU (2022) Policy support for heating and cooling decarbonisation: roadmap. European Commission, Brussels, Belgium

TU Wien, e-think, Fraunhofer ISI, et al (2022) Renewable space heating under the revised Renewable Energy Directive: ENER/C1/2018 494: final report. European Commission, Brussels, Belgium

Eurostat (2023) Eurostat database. https://ec.europa.eu/eurostat/web/main/data/database. Accessed 18 Jul 2023

Fraunhofer ISI, Fraunhofer ISE, IRESS, et al (2016) Map** and analyses of the current and future (2020–2030) heating/cooling fuel deployment (fossil/renewables). Work package 1: final energy consumption for the year 2012. European Commission

Chan Y, Kantamaneni R, Allington M (2015) Study on energy efficiency and energy saving potential in industry and on possible policy mechanisms. ICF Consulting Limited, London, UK

Fleiter T, Elsland R, Rehfeldt M, et al (2017) Profile of heating and cooling demand in 2015. Heat Roadmap Europe

Taibi E, Gielen D, Bazilian M (2012) The potential for renewable energy in industrial applications. Renew Sustain Energy Rev 16:735–744. https://doi.org/10.1016/j.rser.2011.08.039

Berglin N, Berntsson T (1998) CHP in the pulp industry using black liquor gasification: thermodynamic analysis. Appl Therm Eng 18:947–961. https://doi.org/10.1016/S1359-4311(98)00038-6

Jönsson J, Algehed J (2010) Pathways to a sustainable European kraft pulp industry: trade-offs between economy and CO2 emissions for different technologies and system solutions. Appl Therm Eng 30:2315–2325. https://doi.org/10.1016/j.applthermaleng.2010.01.025

Suhr M, Klein G, Kourti I et al (2015) Best available techniques (BAT) reference document for the production of pulp, paper and board. Publications Office of the European Union, Luxembourg

Stubdrup KR, Karlis P, Roudier S, Sancho LD (2016) Best available techniques (BAT) reference document for the production of wood-based panels. Publications Office of the European Union, Luxembourg

U.S. Department of Energy, Industrial Heating Equipment Association (2004) Improving process heating system performance. A sourcebook for industry. U.S. Department of Energy, Washington, D.C.

Suopajärvi H, Umeki K, Mousa E et al (2018) Use of biomass in integrated steelmaking—status quo, future needs and comparison to other low-CO2 steel production technologies. Appl Energy 213:384–407. https://doi.org/10.1016/j.apenergy.2018.01.060

Danish Energy Agency (2022) Technology data for industrial process heat. Danish Energy Agency

US EIA (2018) Manufacturing energy consumption survey (MECS). https://www.eia.gov/consumption/manufacturing/. Accessed 20 Aug 2023

Lovegrove K, Alexander D, Bader R, et al (2019) Renewable energy options for industrial process heat. Australian Renewable Energy Agency, O’Connor

Pardo N, Moya JA (2013) Prospective scenarios on energy efficiency and CO2 emissions in the European iron and steel industry. Energy 54:113–128. https://doi.org/10.1016/j.energy.2013.03.015

He K, Wang L (2017) A review of energy use and energy-efficient technologies for the iron and steel industry. Renew Sustain Energy Rev 70:1022–1039. https://doi.org/10.1016/j.rser.2016.12.007

Worrell E, Phylipsen D, Einstein D, Martin N (2000) Energy use and energy intensity of the U.S. chemical industry. University of California, Berkeley, CA

Saygin D, Patel MK, Worrell E et al (2011) Potential of best practice technology to improve energy efficiency in the global chemical and petrochemical sector. Energy 36:5779–5790. https://doi.org/10.1016/j.energy.2011.05.019

Madlool NA, Saidur R, Hossain MS, Rahim NA (2011) A critical review on energy use and savings in the cement industries. Renew Sustain Energy Rev 15:2042–2060. https://doi.org/10.1016/j.rser.2011.01.005

Usón AA, López-Sabirón AM, Ferreira G, Sastresa EL (2013) Uses of alternative fuels and raw materials in the cement industry as sustainable waste management options. Renew Sustain Energy Rev 23:242–260. https://doi.org/10.1016/j.rser.2013.02.024

Fleiter T, Fehrenbach D, Worrell E, Eichhammer W (2012) Energy efficiency in the German pulp and paper industry—a model-based assessment of saving potentials. Energy 40:84–99. https://doi.org/10.1016/j.energy.2012.02.025

Lipiäinen S, Kuparinen K, Sermyagina E, Vakkilainen E (2022) Pulp and paper industry in energy transition: towards energy-efficient and low carbon operation in Finland and Sweden. Sustain Prod Consumption 29:421–431. https://doi.org/10.1016/j.spc.2021.10.029

IEA (2022) World energy outlook 2022. International Energy Agency, Paris

Cui D, Deng Z, Liu Z (2019) China’s non-fossil fuel CO2 emissions from industrial processes. Appl Energy 254:113537. https://doi.org/10.1016/j.apenergy.2019.113537

Lenz V, Szarka N, Jordan M, Thrän D (2020) Status and perspectives of biomass use for industrial process heat for industrialized countries. Chem Eng Technol 43:1469–1484. https://doi.org/10.1002/ceat.202000077

Saygin D, Gielen DJ, Draeck M et al (2014) Assessment of the technical and economic potentials of biomass use for the production of steam, chemicals and polymers. Renew Sustain Energy Rev 40:1153–1167. https://doi.org/10.1016/j.rser.2014.07.114

Olsson O, Schipfer F (2021) Decarbonizing industrial process heat: the role of biomass. IEA

Nussbaumer T (2003) Combustion and co-combustion of biomass: fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 17:1510–1521. https://doi.org/10.1021/ef030031q

Demirbas A (2005) Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog Energy Combust Sci 31:171–192. https://doi.org/10.1016/j.pecs.2005.02.002

van Loo S, Koppejan J (2008) The handbook of biomass combustion and co-firing. Earthscan, London; Sterling, VA

EIPPCB (2007) Reference document on best available techniques in the production of polymers. EIPPCB, Seville

EIPPCB (2007) Reference document on best available techniques for the manufacture of large volume inorganic chemicals - ammonia, acids and fertilisers. EIPPCB, Seville

Brinkmann T, Giner Santonja G, Schorcht F et al (2014) Best available techniques (BAT) reference document for the production of chlor-alkali. Publications Office of the European Union, Luxembourg

Barthe P, Chaugny M, Roudier S, Delgado Sancho L (2015) Best available techniques (BAT) reference document for the refining of mineral oil and gas industrial emissions. Publications Office of the European Union, Luxembourg

Falcke H, Holbrook S, Clenahan I, et al (2017) Best available techniques (BAT) reference document for the production of large volume organic chemicals. Publications Office of the European Union, Luxembourg

Giner Santonja G, Karlis P, Stubdrup KR et al (2019) Best available techniques (BAT) reference document for the food, drink and milk industries. Publications Office of the European Union, Luxembourg

Remus R, Aguado-Monsonet MA, Roudier S, Sancho L (2013) Best available techniques (BAT) reference document for iron and steel production. Publications Office of the European Union, Luxembourg

Mousa E, Wang C, Riesbeck J, Larsson M (2016) Biomass applications in iron and steel industry: an overview of challenges and opportunities. Renew Sustain Energy Rev 65:1247–1266. https://doi.org/10.1016/j.rser.2016.07.061

Cusano G, Rodrigo Gonzalo M, Farrell F et al (2017) Best available techniques (BAT) reference document for the non-ferrous metals industries. Publications Office of the European Union, Luxembourg

EIPPCB (2007) Reference document on best available techniques in the ceramic manufacturing industry. EIPPCB, Seville

Scalet BM, Garcia Muñoz M, Sissa AQ et al (2013) Best available techniques (BAT) reference document for the manufacture of glass. Publications Office of the European Union, Luxembourg

Schorcht F, Kourti I, Scalet BM et al (2013) Best available techniques (BAT) reference document for the production of cement, lime and magnesium oxide. Publications Office of the European Union, Luxembourg

Mikulčić H, Klemeš JJ, Vujanović M et al (2016) Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process. J Clean Prod 136:119–132. https://doi.org/10.1016/j.jclepro.2016.04.145

Pinto RGD, Szklo AS, Rathmann R (2018) CO2 emissions mitigation strategy in the Brazilian iron and steel sector–from structural to intensity effects. Energy Policy 114:380–393. https://doi.org/10.1016/j.enpol.2017.11.040

Nepomuceno Pereira R, Malico I, Mesquita P, et al (2017) Energy use of cork residues in the Portuguese cork industry. In: Proceedings of the 12th conference on sustainable development of energy, water and environment systems—SDEWES 2017. SDEWES Center, Dubrovnik; Croatia

Beauchemin PA, Tampier M (2008) Emissions from wood-fired combustion equipment. Envirochem Services Inc., North Vancouver, B. C.

Yin C, Rosendahl LA, Kær SK (2008) Grate-firing of biomass for heat and power production. Prog Energy Combust Sci 34:725–754. https://doi.org/10.1016/j.pecs.2008.05.002

Energy and Environmental Analysis, Eastern Research Group (2007) Biomass combined heat and power catalog of technologies. Environmental Protection Agency, U. S

Mladenović R, Dakić D, Erić A et al (2009) The boiler concept for combustion of large soya straw bales. Energy 34:715–723. https://doi.org/10.1016/j.energy.2009.02.003

Koornneef J, Junginger M, Faaij A (2007) Development of fluidized bed combustion—an overview of trends, performance and cost. Prog Energy Combust Sci 33:19–55. https://doi.org/10.1016/j.pecs.2006.07.001

Scala F (2013) Fluidized bed technologies for near-zero emission combustion and gasification. Woodhead Publishing, cambridge, UK

Bayham SC, Breault R, Monazam E (2016) Particulate solid attrition in CFB systems—an assessment for emerging technologies. Powder Technol 302:42–62. https://doi.org/10.1016/j.powtec.2016.08.016

Leckner B (2016) Developments in fluidized bed conversion of solid fuels. Therm Sci 20:1–18. https://doi.org/10.2298/TSCI150703135L

Kleinhans U, Wieland C, Frandsen FJ, Spliethoff H (2018) Ash formation and deposition in coal and biomass fired combustion systems: progress and challenges in the field of ash particle sticking and rebound behavior. Prog Energy Combust Sci 68:65–168. https://doi.org/10.1016/j.pecs.2018.02.001

Obernberger I (2009) Reached developments of biomass combustion technologies and future outlook. In: Proceedings of the 17th European biomass conference. Hamburg, Germany, pp 20–37

Saidur R, Abdelaziz EA, Demirbas A et al (2011) A review on biomass as a fuel for boilers. Renew Sustain Energy Rev 15:2262–2289. https://doi.org/10.1016/j.rser.2011.02.015

da Costa TP, Quinteiro P, Tarelho LA da C, et al (2018) Environmental impacts of forest biomass-to-energy conversion technologies: grate furnace versus fluidised bed furnace. J Clean Prod 171:153–162.https://doi.org/10.1016/j.jclepro.2017.09.287

de Souza-Santos ML (2004) Solid fuels combustion and gasification. Modeling, simulation, and equipment operations. Marcel Dekker, New York, NY

Peterson D, Haase S (2009) Market assessment of biomass gasification and combustion technology for small- and medium-scale applications. National Renewable Energy Laboratory, Golden, CO

Göransson K, Söderlind U, He J, Zhang W (2011) Review of syngas production via biomass DFBGs. Renew Sustain Energy Rev 15:482–492. https://doi.org/10.1016/j.rser.2010.09.032

Thomson R, Kwong P, Ahmad E, Nigam KDP (2020) Clean syngas from small commercial biomass gasifiers; a review of gasifier development, recent advances and performance evaluation. Int J Hydrogen Energy 45:21087–21111. https://doi.org/10.1016/j.ijhydene.2020.05.160

Hanchate N, Ramani S, Mathpati CS, Dalvi VH (2021) Biomass gasification using dual fluidized bed gasification systems: a review. J Clean Prod 280:123148. https://doi.org/10.1016/j.jclepro.2020.123148

Bain RL, Broer K (2011) Gasification. In: Brown RC (ed) Thermochemical processing of biomass. Conversion into fuels, chemicals and power. Wiley, Chichester, pp 47–77

Sansaniwal SK, Pal K, Rosen MA, Tyagi SK (2017) Recent advances in the development of biomass gasification technology: a comprehensive review. Renew Sustain Energy Rev 72:363–384. https://doi.org/10.1016/j.rser.2017.01.038

Dimpl E (2011) Small-scale electricity generation from biomass. Experience with small-scale technologies for basic energy supply. Part I: biomass gasification, 2nd ed. GIZ Hera, Eschborn

Schmid JC, Benedikt F, Fuchs J et al (2021) Syngas for biorefineries from thermochemical gasification of lignocellulosic fuels and residues—5 years’ experience with an advanced dual fluidized bed gasifier design. Biomass Conv Bioref 11:2405–2442. https://doi.org/10.1007/s13399-019-00486-2

Karl J, Pröll T (2018) Steam gasification of biomass in dual fluidized bed gasifiers: a review. Renew Sustain Energy Rev 98:64–78. https://doi.org/10.1016/j.rser.2018.09.010

Claude V, Courson C, Köhler M, Lambert SD (2016) Overview and essentials of biomass gasification technologies and their catalytic cleaning methods. Energy Fuels 30:8791–8814. https://doi.org/10.1021/acs.energyfuels.6b01642

IRENA (2015) A background paper to “renewable energy in manufacturing”. IRENA, Abu Dhabi

Podschelne C, Ciolkosz D (2013) Residential wood heat in the Northeast. In: Jacobson M, Ciolkosz D (eds) Wood-based energy in the northern forests. Springer, New York, New York, NY, pp 111–124

Hansson J, Berndes G, Johnsson F, Kjärstad J (2009) Co-firing biomass with coal for electricity generation—an assessment of the potential in EU27. Energy Policy 37:1444–1455. https://doi.org/10.1016/j.enpol.2008.12.007

Khorshidi Z, Ho MT, Wiley DE (2014) The impact of biomass quality and quantity on the performance and economics of co-firing plants with and without CO2 capture. Int J Greenhouse Gas Control 21:191–202. https://doi.org/10.1016/j.ijggc.2013.12.011

Roni MS, Chowdhury S, Mamun S et al (2017) Biomass co-firing technology with policies, challenges, and opportunities: a global review. Renew Sustain Energy Rev 78:1089–1101. https://doi.org/10.1016/j.rser.2017.05.023

Demirbaş A (2003) Sustainable cofiring of biomass with coal. Energy Convers Manage 44:1465–1479

Sahu SG, Chakraborty N, Sarkar P (2014) Coal–biomass co-combustion: an overview. Renew Sustain Energy Rev 39:575–586. https://doi.org/10.1016/j.rser.2014.07.106

Rahman A, Rasul MG, Khan MMK, Sharma S (2015) Recent development on the uses of alternative fuels in cement manufacturing process. Fuel 145:84–99. https://doi.org/10.1016/j.fuel.2014.12.029

Pardo N, Vatopoulos K, Krook-Riekkola A, Moya JA (2012) Heat and cooling demand and market perspective. Publications Office of the European Union, Luxembourg

Babich A, Senk D (2013) Biomass use in the steel industry: back to the future? Stahl Eisen 133:57–67

Suopajärvi H, Pongrácz E, Fabritius T (2013) The potential of using biomass-based reducing agents in the blast furnace: a review of thermochemical conversion technologies and assessments related to sustainability. Renew Sustain Energy Rev 25:511–528. https://doi.org/10.1016/j.rser.2013.05.005

Lake A, Rezaie B, Beyerlein S (2017) Review of district heating and cooling systems for a sustainable future. Renew Sustain Energy Rev 67:417–425. https://doi.org/10.1016/j.rser.2016.09.061

Werner S (2017) International review of district heating and cooling. Energy 137:617–631. https://doi.org/10.1016/j.energy.2017.04.045

Ericsson K, Werner S (2016) The introduction and expansion of biomass use in Swedish district heating systems. Biomass Bioenerg 94:57–65. https://doi.org/10.1016/j.biombioe.2016.08.011

Acknowledgements

The work was supported by Fundação para a Ciência e a Tecnologia, through IDMEC, under LAETA [project UIDB/50022/2020]. Isabel Malico expresses her gratitude to Lucas Saffian for the valuable help drawing the sketches included in this chapter.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Malico, I. (2024). Biomass for Industrial and District Heating. In: Gonçalves, A.C., Malico, I. (eds) Forest Bioenergy. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-48224-3_9

Download citation

DOI: https://doi.org/10.1007/978-3-031-48224-3_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-48223-6

Online ISBN: 978-3-031-48224-3

eBook Packages: EnergyEnergy (R0)