Abstract

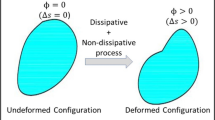

Hot-section components made by nickel-based superalloy for areo-engines always experience a long-term elevated temperature operating environment. Mechanical load caused more serious low cycle fatigue (LCF) at elevated temperature due to the reduction of mechanical properties. It is essential to investigate LCF under elevated temperature, especially LCF behavior and fatigue life. This paper considered the isothermal LCF for disc superalloy GH4169 at elevated temperature from the perspective of irreversible thermodynamics and degradation. A strain-controlled LCF behavior simulation program coded in MATLAB program based on Chaboche plastic constitutive model to simulate cyclic stress–strain responses and entropy generation. According to the results of accumulation of entropy generation in LCF process, a proposed model utilizing Belehradek law to fit fatigue fracture entropy generation under different loading conditions. A defined damage factor based on degradation-theorem and entropy generation was proposed to describe the evolution of fatigue damage in LCF. A damage evolution method utilized the entropy generation are adopted to estimate fatigue life. Compared with the experiment lives and predicted results from classic life prediction model, such as Ostergren and SWT models, this method can estimate the fatigue life for LCF at elevated temperature reasonably. Finally, the damage evolution method provided a suitable approach to monitor remaining life for elevated temperature LCF for GH4169.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen, G., Zhang, Y., Xu, D.K., et al.: Low cycle fatigue and creep-fatigue interaction behavior of nickel-base superalloy GH4169 at elevated temperature of 650 °C. Mater. Sci. Eng. A 655, 175–182 (2016)

Cheng, L., Xue, X., Tang, B., et al.: Deformation behavior of hot-rolled IN718 superalloy under plane strain compression at elevated temperature. Mater. Sci. Eng. A 606, 24–30 (2014)

Yan, P., Feng, Y.N., Qiao, S., Zhang, Y., Liu, Q., Shao, X.: Research progress on low cycle fatigue of nickel-based wrought superalloys. Chin. J. Rare Metals 45(6), 740 (2021)

Fournier, D., Pineau, A.: Low cycle fatigue behavior of Inconel 718 at 298 K and 823 K. Metall. Trans. A 8, 1095–1105 (1997)

Prasad, K., Sarkar, R., Ghosal, P., et al.: High temperature low cycle fatigue deformation behaviour of forged IN718 superalloy turbine disc. Mater. Sci. Eng. A 568, 239–245 (2013)

Zhang, X.C., Li, H.C., Zeng, X., et al.: Fatigue behavior and bilinear Coffin–Manson plots of Ni-based GH4169 alloy with different volume fractions of δ phase. Mater. Sci. Eng. A 682, 12–22 (2017)

Wang, L., Liu, Y.M., Chen, G., Liu, J.: Low cycle fatigue damage mechanism of GH4169 nickel-based superalloy at elevated temperature. Mater. Mech. Eng. 43(1), 45 (2019)

Yao, L.L., Zhang, X.C., Liu, F., Tu, S.D., Ma, C.: High-temperature low-cycle fatigue properties of GH4169 Ni-based superalloy. Mater. Mech. Eng. 40(4), 25 (2016)

Coffin, L.F., Tavemelli, J.F.: The cyclic straining and fatigue of metals. Trans. Metall. Soc. AIME 215, 794 (1959)

Li, Z., Li, S., Xu, G., et al.: The framework of hot corrosion fatigue life estimation of a PM superalloy using notch fatigue methodology combined with pit evolution. Int. J. Fatigue 153, 106483 (2021)

Smith, K.N.: A stress–strain function for the fatigue of metals. J. Mater. 5, 767–778 (1970)

Liu, L.L., Hu, D.Y., Li, D., et al.: Effect of grain size on low cycle fatigue life in compressor disc superalloy GH4169 at 600 °C. Procedia Struct. Integrity 7, 174–181 (2017)

Ostergren, W.J.: A damage function and associated failure equations for predicting hold time and frequency effects in elevated temperature, low cycle fatigue. J. Test. Eval. 4(5), 327–339 (1976)

Miner, M.A.: Cumulative damage in fatigue. ASME J. Appl. Mech. 12(3), A159–A164 (1945)

Chaboche, J.L., Lesne, P.M.A.: A non-linear continuous fatigue damage model. Fatigue Fract. Eng. Mater. Struct. 11(1), 1–17 (1988)

Duyi, Y., Zhenlin, W.: A new approach to low-cycle fatigue damage based on exhaustion of static toughness and dissipation of cyclic plastic strain energy during fatigue. Int. J. Fatigue 23(8), 679–687 (2001)

Liu, Y., Mahadevan, S.: Stochastic fatigue damage modeling under variable amplitude loading. Int. J. Fatigue 29(6), 1149–1161 (2007)

Krajcinovic, D., Lemaitre, J.: Continuum Damage Mechanics: Theory and Applications. Springer-Verlag, Berlin (1987)

Bhattacharya, B., Ellingwood, B.: Continuum damage mechanics analysis of fatigue crack initiation. Int. J. Fatigue 20(9), 631–639 (1998)

Naderi, M., Amiri, M., Khonsari, M.M.: On the thermodynamic entropy of fatigue fracture. Proc. R. Soc. A Math. Phys. Eng. Sci. 466(2114), 423–438 (2010)

Basaran, C., Nie, S.: An irreversible thermodynamics theory for damage mechanics of solids. Int. J. Damage Mech. 13(3), 205–223 (2004)

Basaran, C., Yan, C.Y.: A thermodynamic framework for damage mechanics of solder joints. ASME J. Electron. Packag. 120(4), 379–384 (1988)

Doelling, K.L., Ling, F.F., Bryant, M.D., et al.: An experimental study of the correlation between wear and entropy flow in machinery components. J. Appl. Phys. 88(5), 2999–3003 (2000)

Naderi, M., Khonsari, M.M.: A thermodynamic approach to fatigue damage accumulation under variable loading. Mater. Sci. Eng. A 527(23), 6133–6139 (2010)

Bryant, M.D., Khonsari, M.M., Ling, F.F.: On the thermodynamics of degradation. Proc. R. Soc. A Math. Phys. Eng. Sci. 464(2096), 2001–2014 (2008)

Liakat, M., Khonsari, M.M.: Entropic characterization of metal fatigue with stress concentration. Int. J. Fatigue 70, 223–234 (2015)

Chaboche, J.L.: Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 5(3), 247–302 (1989)

Liu, L.F.: Research on thermomechanical fatigue behavior and life prediction approaches of nickel-based superalloy. M.S. thesis, Nan**g University of Aeronautics and Astronautics, Nan**g (2019)

Sun, J., Yuan, H.: Cyclic plasticity modeling of nickel-based superalloy Inconel 718 under multi-axial thermo-mechanical fatigue loading conditions. Int. J. Fatigue 119, 89–101 (2019)

Wang, R.Z., Wang, J., Gong, J.G.: Creep-fatigue behaviors and life assessments in two nickel-based superalloys. J. Press. Vessel Technol. 140(3) (2018)

Wei, D.S., Shi, L., Wang, Y.R.: Experimental study of the cyclic mechanical behaviour of two Ni-based superalloys at evaluated temperature. Mater. Sci. Eng. A 569, 124–131 (2013)

Cheng, L.Y., Wang, R.Z., Wang, J.: Cycle-dependent creep-fatigue deformation and life predictions in a nickel-based superalloy at elevated temperature. Int. J. Mech. Sci. 206, 106628 (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

**a, S., Ding, S., Li, Z., Zuo, L., Bao, S., Li, G. (2024). A Damage Evolution Method for Estimating Low Cycle Fatigue Life of GH4169 Alloy Based on Thermodynamic Entropy Generation at Elevated Temperature. In: Li, S. (eds) Computational and Experimental Simulations in Engineering. ICCES 2023. Mechanisms and Machine Science, vol 146. Springer, Cham. https://doi.org/10.1007/978-3-031-44947-5_59

Download citation

DOI: https://doi.org/10.1007/978-3-031-44947-5_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-44946-8

Online ISBN: 978-3-031-44947-5

eBook Packages: EngineeringEngineering (R0)