Abstract

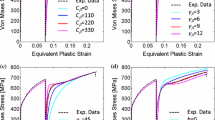

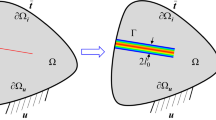

This paper presents a rate-dependent extension of Jia-Zang ductile fracture model with five parameters considering void nucleation, growth and coalescence. A series of ductile fracture tests is designed and conducted on aluminum alloy (6016-T6) specimens, which allows wide ranges for stress state and strain rate (0.1–100/s) under room temperature. A hybrid experiment-simulation method is employed to investigate the effects of stress state and strain rate on the material ductility. The results indicate an increasing equivalent plastic strain to fracture for each specimen as the strain rate increases from 0.1/s to 100/s. In addition, several nonlinear empirical functions are used to extend the original model parameters with strain rate dependent integrated. Subsequently, an uncoupled ductile fracture model considering strain rate dependent is developed, which can work from quasi-static to dynamic scenarios.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Yan, Z., **ao, A., Zhao, P., Cui, X., Yu, H., Lin, Y.: Deformation behavior of 5052 aluminum alloy sheets during electromagnetic hydraulic forming. Int. J. Mach. Tools Manuf. 179, 103916 (2022)

Yu, H.P., Zheng, Q.L.: Forming limit diagram of DP600 steel sheets during electrohydraulic forming. Int. J. Adv. Manuf. Technol. 104(1–4), 743–756 (2019)

Ma, Y., et al.: Investigation on formability enhancement of 5A06 aluminium sheet by impact hydroforming. CIRP Ann. 67(1), 281–284 (2018)

Li, H., Fu, M.W., Lu, J., Yang, H.: Ductile fracture: experiments and computations. Int. J. Plast. 27(2), 147–180 (2011)

Gurson, A.L.: Continuum theory of ductile rupture by void nucleation and growth: part I-yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99(1), 2–15 (1977)

Tvergaard, V.: On localization in ductile materials containing spherical voids. Int. J. Fract. 18(4), 237–252 (1982)

Bai, Y., Wierzbicki, T.: Application of extended Mohr-Coulomb criterion to ductile fracture. Int. J. Fract. 161, 1–20 (2009)

Lou, Y.S., Chen, L., Clausmeyer, T., Tekkaya, A.E., Yoon, J.W.: Modeling of ductile fracture from shear to balanced biaxial tension for sheet metals. Int. J. Solids Struct. 112, 169–184 (2017)

Jia, Z., Mu, L., Guan, B., Qian, L.-Y., Zang, Y.: Experimental and numerical study on ductile fracture prediction of aluminum alloy 6016–T6 sheets using a phenomenological model. J. Mater. Eng. Perform. 31, 867–881 (2022)

Erice, B., Roth, C.C., Mohr, D.: Stress-state and strain-rate dependent ductile fracture of dual and complex phase steel. Mech. Mater. 116, 11–32 (2018)

Ji, C., Li, Z.G., Liu, J.G.: Development of an improved MMC-based fracture criterion characterizing the anisotropic and strain rate-dependent behavior of 6061–T5 aluminum alloy. Mech. Mater. 150, 103598 (2020)

Lim, S.J., Huh, H.: Ductile fracture behavior of BCC and FCC metals at a wide range of strain rates. Int. J. Impact Eng. 159, 104050 (2022)

Jia, Z., Guan, B., Zang, Y., Wang, Y., Mu, L.: Modified Johnson-Cook model of aluminum alloy 6016–T6 sheets at low dynamic strain rates. Mater. Sci. Eng. A 820, 141565 (2021)

Ma, H.J., Huang, L., Tian, Y., Li, J.J.: Effects of strain rate on dynamic mechanical behavior and microstructure evolution of 5A02-O aluminum alloy. Mater. Sci. Eng. A 606, 233–239 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Jia, Z., Mu, L., Liu, Y., Zang, Y. (2024). An Extended Ductile Fracture Prediction Model Considering Strain Rate Effects. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-42093-1_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-42093-1_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-42092-4

Online ISBN: 978-3-031-42093-1

eBook Packages: EngineeringEngineering (R0)