Abstract

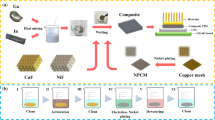

Microchannels on metallic substrates are essential parts of microreactors, micro heat exchangers, micro heat sinks, and fuel cell bipolar plates. Because of superior properties, such as good corrosion resistance, excellent thermal conductivity, high strength, excellent ductility and structural stability, composite metal foils are gaining popularity as substrates for microchannels. With the increasing demands of low cost, high efficiency and accuracy, novel micro forming technologies must be capable of creating intricate and precise micro features of microchannels at a low cost. An ultra-thin metal foil rolling for the fabrication of micro composite channels is proposed in this study, which can improve product function and reduce operational costs. Copper/ stainless steel 304L (SS304L) composite foils with a thickness of 0.41 mm after annealing treatment at 800 ℃ and holding for 0.5 h, 1.0 h and 2.0 h are used to fabricate microchannels under the rolling reduction of 60.9%. The hardness of composite foils has been characterised before and after different annealing processes, in which the hardness decreases due to the synergistic effects of decreased dislocation density, grain coarsening and phase transformation. Further, the formability of composite foils after annealing is discussed. In addition, the processing characteristics, material deformation behaviours and mechanisms during micro rolling are also investigated.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Elyasi, M., Khatir, F.A., Hosseinzadeh, M.: Manufacturing metallic bipolar plate fuel cells through rubber pad forming process. Int. J. Adv. Manuf. Technol. 89(9–12), 3257–3269 (2016). https://doi.org/10.1007/s00170-016-9297-6

Deng, D., **e, Y., Chen, L., Chen, X.: Experimental investigation on laser micromilling of SiC microchannels. Int. J. Adv. Manuf. Technol. 101(1–4), 9–21 (2018). https://doi.org/10.1007/s00170-018-2800-5

Zhang, X., Pan, T., Flood, A., Chen, Y., Zhang, Y., Liou, F.: Investigation of copper/stainless steel multi-metallic materials fabricated by laser metal deposition. Mater. Sci. Eng. A 811, 141071 (2021)

Weiss, M., Zhang, P., Pereira, M.P., Rolfe, B.F., Wilkosz, D.E., Hodgson, P.D.: Understanding size effects and forming limits in the micro-stam** of industrial stainless steel foils. Metals 11(1), 38 (2020)

Song, Y., et al.: Review on current research of materials, fabrication and application for bipolar plate in proton exchange membrane fuel cell. Int. J. Hydrog. Energy 45(54), 29832–29847 (2020)

Abeyrathna, B., Zhang, P., Pereira, M.P., Wilkosz, D., Weiss, M.: Micro-roll forming of stainless steel bipolar plates for fuel cells. Int. J. Hydrog. Energy 44(7), 3861–3875 (2019)

Huang, J., Deng, Y., Yi, P., Peng, L.: Experimental and numerical investigation on thin sheet metal roll forming process of micro channels with high aspect ratio. Int. J. Adv. Manuf. Technol. 100(1–4), 117–129 (2018). https://doi.org/10.1007/s00170-018-2606-5

Ren, M., Lin, F., Jia, F., **e, H., Yang, M., Jiang, Z.: Micro rolling fabrication of copper/SS304L micro composite channels. J. Manuf. Process. 90, 1–13 (2023)

**e, H.B., Manabe, K., Furushima, T., Tada, K., Jiang, Z.Y.: An experimental and numerical investigation on micro rolling for ultra-thin strip. Int. J. Mater. Form. 9(3), 405–412 (2015). https://doi.org/10.1007/s12289-015-1229-8

Ren, M., et al.: Effect of heat treatment on the microstructure and mechanical properties of copper/SS304L composite sheets. Vacuum 204, 111307 (2022)

Ren, M., et al.: Evolutions of microstructure and mechanical properties of copper/SS304L composite micro channels during micro rolling. Mater. Sci. Eng. A 871, 144881 (2023)

Jiang, Z.: Ribbed strip rolling by three-dimensional finite element method combining extremely thin array of elements. Front. Mech. Eng. 5(1), 52–60 (2009)

Acknowledgements

The authors acknowledge the financial support from Australian Research Council (ARC, Grant Nos. DP190100408). The first author appreciates the University of Wollongong for the scholarship support.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Ren, M. et al. (2024). Novel Fabrication of Ultra-thin Copper/SS304L Composite Microchannels. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-40920-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-40920-2_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-40919-6

Online ISBN: 978-3-031-40920-2

eBook Packages: EngineeringEngineering (R0)