Abstract

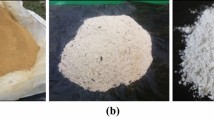

Peat is Geotechnically problematic for any infrastructure as it contains a lot of moisture, low shear strength, and high compressibility. This paper particularly focuses on the improvement of peat in Ziro valley, Arunachal Pradesh using cement and rice husk ash. An environmentally responsible replacement to final disposal using rice husk ash as a soil stabiliser because it is a waste product from the rice industry with pozzolanic qualities. By adjusting the amount of rice husk ash put to the peat soil during all of the usual laboratory procedures as 6, 8, and 12% by weight of soil and cement as 5, 10, 15, 20 and 25%. The strength of peat is greatly enhanced by cement, neutralises the impact of organic matter content, and lessens the impact of acidity. with an increasing amount of cement material, the dry density increases and the optimum water content decreases. With increase in RHA content, MDD decreases but OMC increases. Both unsoaked and soaked CBR test were carried out on peat mixed with cement and RHA. For the test specimen made up of soil, cement, and rice husk ash, it was noticed that the mixture of peat-cement-RHA significantly improved the strength characteristic of parent peat soil. S + 25C and S + 25C + 8RHA can be recommended for treating subgrade.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Hoikkala S, Leppänen M, Lahtinen P (1996) Mass stabilization of peat in road construction. XII Nordiska Geoteknikermötet NGM, Reykjavík 1:26–28

Den Haan EJ (1998) Cement based stabilizers for Dutch organic soils. In: Problematic soils, pp 53–56

Bergado DT, Anderson LR, Miura N, Balasubramaniam AS (1996) Soft ground improvement in lowland and other environments. ASCE

Evans J, Ruffing D, Elton D (2021) Fundamentals of ground improvement engineering. CRC Press

Sherwood P (1993) Soil stabilization with cement and lime. H.M stationery office, London, p 153

Porbaha A, Shibuya S, Kishida T (2000) State of the art in deep mixing technology. Part III: geomaterial characterization. In: Proceedings of the institution of civil engineers-ground improvement, vol 4, issue 3, pp 91–110

Chaudhary DS, Jollands MC (2004) Characterization of rice hull ash. J Appl Polym Sci 93(1):1–8

Quispe I, Navia R, Kahhat R (2019) Life cycle assessment of rice husk as an energy source. a Peruvian case study. J Clean Prod 209:1235–1244

Paul A, Hussain M (2020) Sustainable use of GGBS and RHA as a partial replacement of cement in the stabilization of Indian Peat. Int J Geosynthetics Ground Eng 6:1–15

Jittin V, Bahurudeen A, A**kya SD (2020) Utilisation of rice husk ash for cleaner production of different construction products. J Clean Prod 263:121578

He J, Jie Y, Zhang J, Yu Y, Zhang G (2013) Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem Concr Compos 37:108–118

Nimwinya E, Arjharn W, Horpibulsuk S, Phoo-Ngernkham T, Poowancum A (2016) A sustainable calcined water treatment sludge and rice husk ash geopolymer. J Clean Prod 119:128–134

Chaudhary DS, Jollands MC, Cser F (2004) Recycling rice hull ash: a filler material for polymeric composites? Adv Polym Technol: J Polym Process Inst 23(2):147–155

Nair DG, Jagadish KS, Fraaij A (2006) Reactive pozzolanas from rice husk ash: an alternative to cement for rural housing. Cem Concr Res 36(6):1062–1071

Rahman MA (1987) Effects of cement-rice husk ash mixtures on geotechnical properties of lateritic soils. Soils Found 27(2):61–65

Zhang MH, Lastra R, Malhotra VM (1996) Rice-husk ash paste and concrete: some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste. Cem Concr Res 26(6):963–977

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Jumsi, N., Kalita, A. (2024). The Pozzolanic Effect of Rice Husk Ash on the California Bearing Ratio Behaviour of Arunachal Peat with Cement as Admixture. In: Nehdi, M., Hung, M.K., Venkataramana, K., Antony, J., Kavitha, P.E., Beena B R (eds) Proceedings of SECON’23. SECON 2023. Lecture Notes in Civil Engineering, vol 381. Springer, Cham. https://doi.org/10.1007/978-3-031-39663-2_33

Download citation

DOI: https://doi.org/10.1007/978-3-031-39663-2_33

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-39662-5

Online ISBN: 978-3-031-39663-2

eBook Packages: EngineeringEngineering (R0)