Abstract

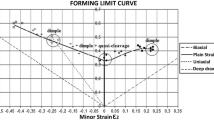

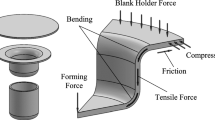

A study on the stam** process of a chair surface with complex profiles made from SS400 material sheets, this part is welded to the mounting bracket used for transporting mining workers in the mines. During the stam** process, the seat surface often appears tearing at the front position of the seat. This position has non-uniform deformation, a large degree of deformation is easy to tear, and the surface after deformation will be uneven, affecting the quality and aesthetics of the product. Defects occur when stam** the seat surface due to many reasons such as the calculation of the initial profile of the workpiece, selection of geometrical parameters, and inappropriate technology. Therefore, this study has conducted a simulation of the stam** process with different types of billet profiles, after being simulated stam**, the deformation and thickness will be determined at many locations. From there, select the appropriate billet profile so that the part after stam** does not appear to be torn, ensuring the size requirements and no need to add rim cutting operations. The suitable workpiece profile will be simulated and verified with the corresponding experiment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Luyen TT, Tong VC, Nguyen DT (2021) A simulation and experimental study on the deep drawing process of SPCC sheet using the graphical method. Alexandria Eng J 61(3):2472–2483. https://doi.org/10.1016/j.aej.2021.07.009

The-Thanh L, Tien-Long B, The-Van T, Duc-Toan N (2019) A study on a deep-drawing process with two sha** states for a fuel-filter cup using combined simulation and experiment. Adv Mech Eng 11(8):1–11. https://doi.org/10.1177/1687814019872674

Wang J, Goel A, Yang F, Gau JT (2009) Blank optimization for sheet metal forming using multi-step finite element simulations. Int J Adv Manuf Technol 40(7–8):709–720. https://doi.org/10.1007/s00170-008-1383-y

Starman B, Cafuta G, Mole N (2021) A method for simultaneous optimization of blank shape and forming tool geometry in sheet metal forming simulations. Metals (Basel) 11(4):1–19. https://doi.org/10.3390/met11040544

Nguyen D et al (2014) Formability improvement and blank shape definition for deep drawing of cylindrical cup with complex curve profile from SPCC sheets using FEM. J Cent South Univ 21:27–34

Hai VG, Minh NTH, Nguyen DT (2020) A study on experiment and simulation to predict the spring-back of SS400 steel sheet in large radius of V-bending process. Mater Res Express 7. https://doi.org/10.1088/2053-1591/ab67f5

Voce E (1978) The relationship between stress and strain for homogeneous deformation. J Inst Metals 74:537–562

Luyen T-T, Pham Q-T, Kim Y-S, Nguyen D-T (2019) Application/comparison study of a graphical method of forming limit curve estimation for DP590 steel sheets. J Korean Soc Precis Eng 36(9):883–890. https://doi.org/10.7736/kspe.2019.36.9.883

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Luyen, TT., Nguyen, DT., Nguyen, VN., Pham, TH. (2023). FEM Simulation and Experimental Study on Improving the Forming Ability in Stam** SS400 Sheet Material with a Variable Blank Profile. In: Long, B.T., et al. Proceedings of the 3rd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2022). MMMS 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-31824-5_56

Download citation

DOI: https://doi.org/10.1007/978-3-031-31824-5_56

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-31823-8

Online ISBN: 978-3-031-31824-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)